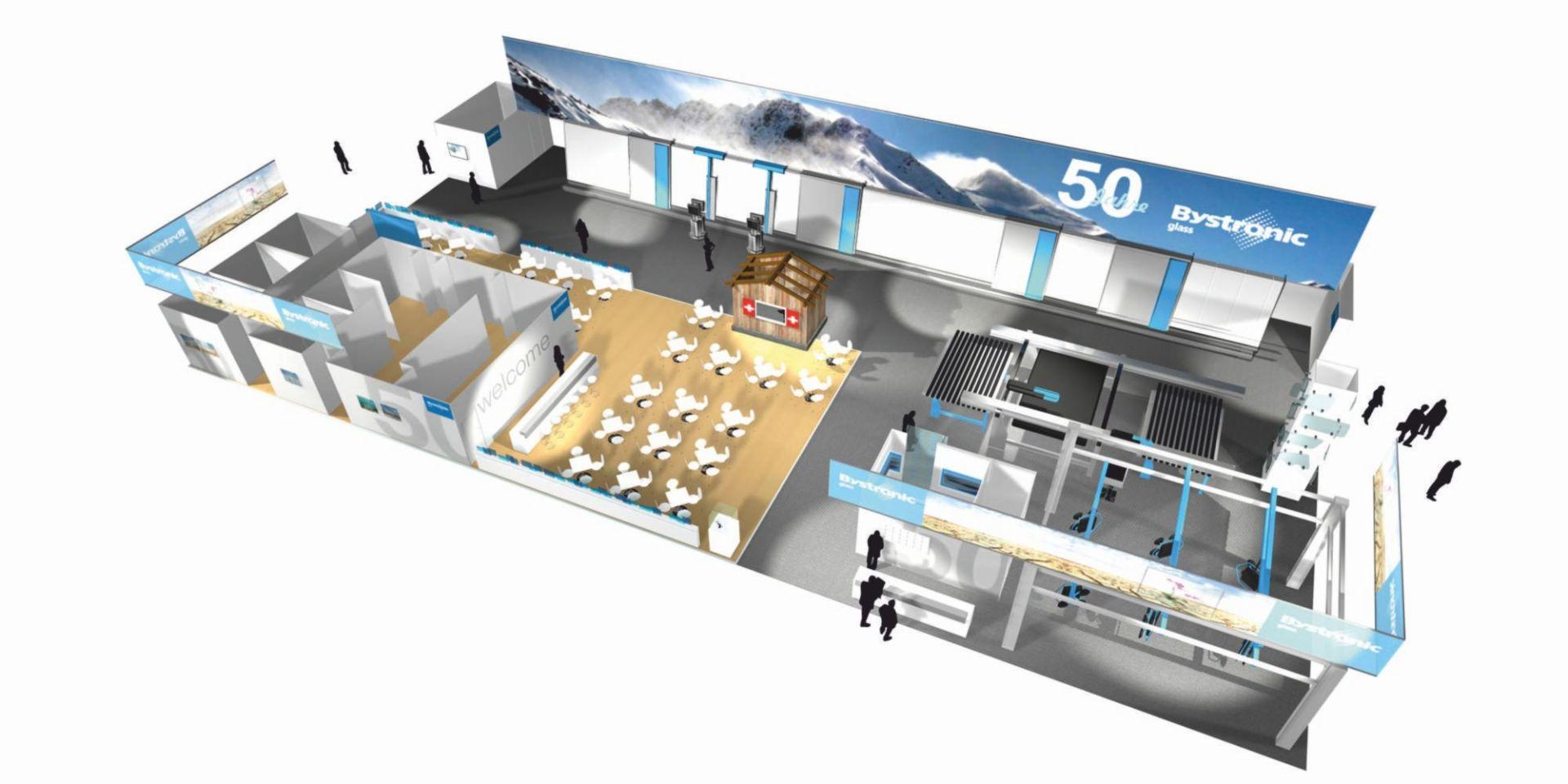

For Bystronic glass, the 2014 glasstec trade fair, which will take place between the 21st and 24th of October in Düsseldorf, will be characterised by the 50th anniversary of the Bützberg location (Switzerland). Together with its customers, Bystronic glass will celebrate with a daily “Swiss Hour” between 17:00 and 18:00 complete with Swiss culinary delights.

Bystronic glass will use its exhibition space to present high speed solutions for glass processing in the architectural and automotive glass sectors. Moderated live presentations of the machines that will take place several times per day will provide visitors with deeper insights into the fascinating technologies. Once again, Bystronic glass will emphasise its preferred partner cooperation with HEGLA in a spatial manner. The trade fair stands of both companies are located next to each other in Hall 14, meaning that customers will be able to comfortably conduct joint talks with experts from both companies.

The Bystronic glass exhibits at a glance:

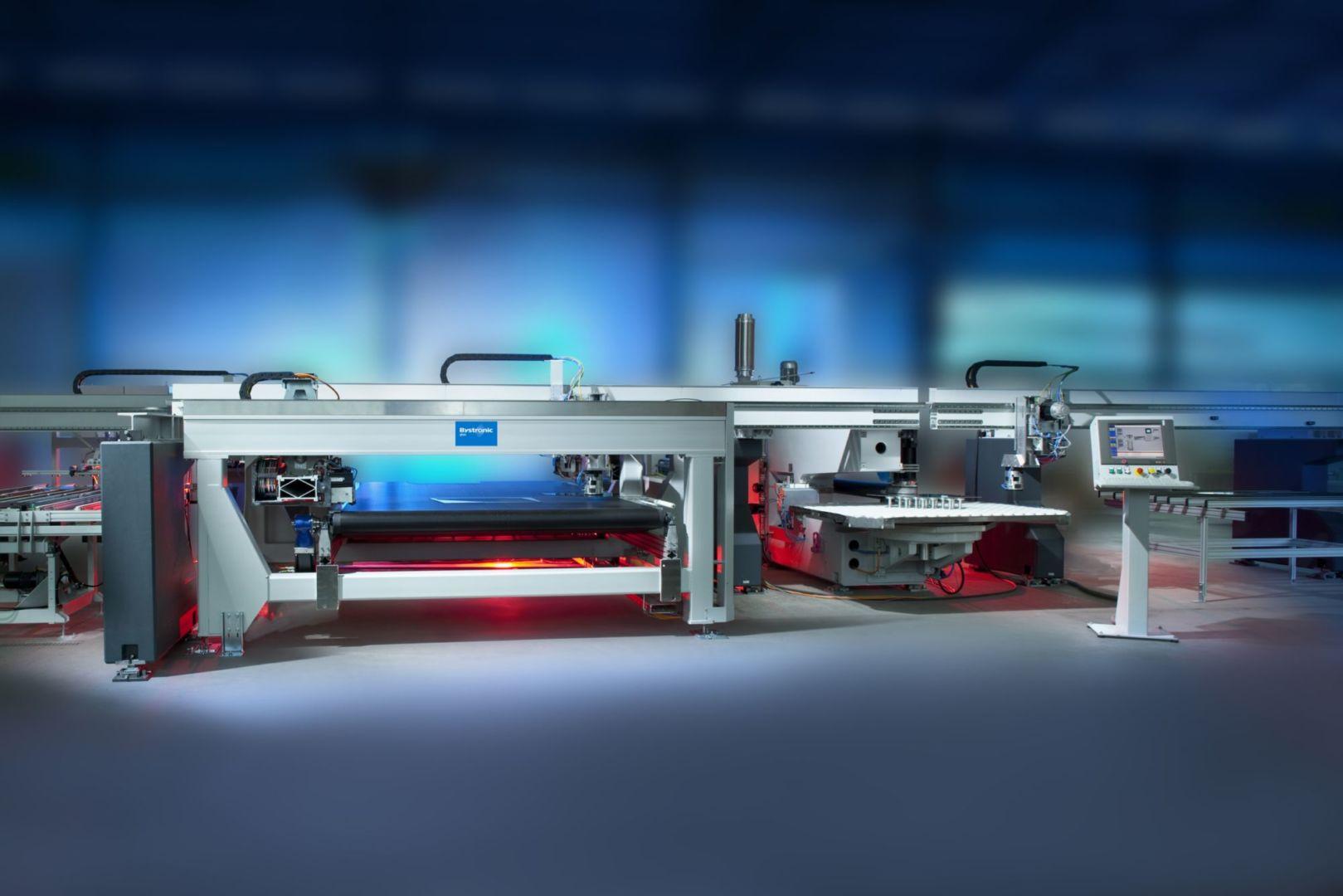

Benchmark in the field of triple insulating glass production

The rapidinsulating glass production line speed’line is able to produce triple insulating glass units in the same time it takes other lines to produce double insulating glass units. This speed’line is characterised by numerous further developments including a new control unit with a higher dynamism and even more flexible options for customers involved in the production of warm edge insulating glasses.

The best possible cycle time is guaranteed by the utilisation of the following unit components: two tps’applicator components arranged one after the other for the application of the TPS® Thermo Plastic Spacer, the speed’assembler, the press for the quick assembly and gas-filling of triple insulating glass units and the speed’sealer sealing robot that, with its dynamic mixing system and the maximum volume flow of up to six litres per minute, enables a rapid sealing.

New applicator for flexible IG spacers

Bystronic glass has further developed its flexspacer’applicator for the application of flexible IG spacers. The core of this machine is a new gear pump that applies the butyl onto the flexible spacer in a volume-accurate manner. Consequently, Bystronic glass continues to be the only provider that offers automated production solutions for all common warm edge spacer systems.

Accurate cost determination via software solution

With the new Total Cost of Ownership (TCO) software, Bystronic glass is in a position to simulate various unit configurations for the customers and to accurately determine certain parameters such as cycle times as well as production and logistics costs, etc. The results assist the customer with the optimisation of their production processes and the selection of the correct spacer type.

Furthermore, it is possible to generate a detailed Return on Investment calculation with the aid of the TCO software.

Glass handling – take it easy

In addition to the insulating glass line, customers will also be able to try a selection of rational handling equipment for all flat glass and plate processing sectors for themselves. This also includes the best seller, the Easy-Lift, which has been convincing customers from the glass processing industry with its rigid guidance and its own low own weight since 1998.

In recent years, the handling equipment has also gradually asserted itself with large window manufacturers due to the fact that it is extremely flexible in terms of frame design and therefore meets their special requirements.

Quick and precise pre-processing of automotive glass

Bystronic glass has been extremely successful on the market for many years with the champ’speed machine generation for the pre-processing of automotive glass. Almost half of all passenger cars are equipped with an automotive lite that was produced on a Bystronic glass unit. The champ’speed 2in1 version is the first machine in the world that can break automotive glass with or without a template on a single machine. At glasstec 2014, Bystronic glass will present the numerous new and further developments to the champ’speed in a multimedia manner in an Automotive Innovation Center.

Service – wherever our customers need us

Right from the very first minute, Bystronic glass supports its customers during the planning of their unit. The customer service department is then on hand all over the world for the delivery of spare parts and on-site support. Maintenance contracts and individual training sessions round off the range of services on offer. Our expert contact partners will be on hand at our glasstec trade fair stand to provide information regarding the Bystronic glass service.