Responsible Partner

Customer experience

At the heart of Glaston’s strategy and values is success with its customers. By creating more customer-oriented operating practices, the company adds customer value and continually improves the customer experience.

As the operating environment changes, customers’ requirements and expectations of Glaston increase. Higher quality and more versatile features are continually required from customers’ end products. Glass processing machines must be able to produce larger, more uniform and thinner glass surfaces. Production must also be able to adapt flexibly to making different types of glass.

Glaston develops technologies and solutions that meet these changing customer needs, and product development is often done in partnership with customers.

One of Glaston’s strategic targets is related to customer satisfaction. The target is that customers’ recommendation rate (Net Promoter Score, NPS) is above 40 by 2025.

In 2023, the customer recommendation rate NPS was 62. As the number of respondents was relatively low, the results cannot be considered fully representative.

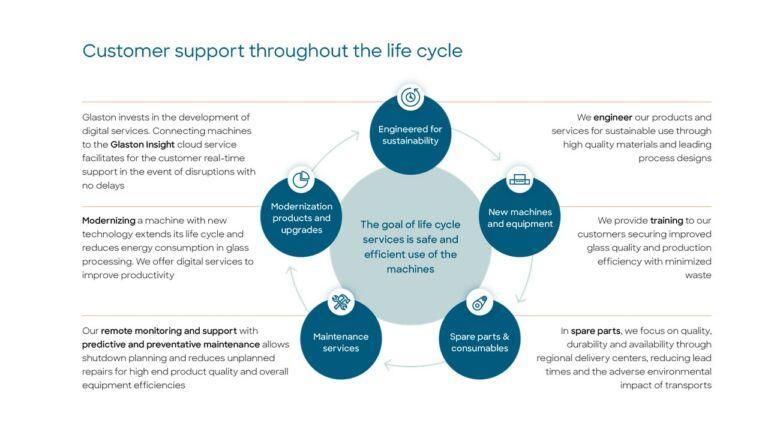

Support throughout the life-cycle

Glass processing machines are long-term investments for their owners as, depending on the machine, they have fairly long operating lives, some of the lines up to 20 years. The machines are designed to withstand constant use at high utilization rates. At Glaston, we pay special attention to the quality and durability of the materials used in our machines.

Our production and assembly processes and installation methods are designed to promote product quality and reliability as well as the safety of installers and customers.

In accordance with our life cycle model, we have been actively developing the maintenance services, as regular service intervals increase product life and safety. Glaston has over 100 different upgrade products for different models of machine. Modernizing a machine with new technology extends its operating life, improves end product quality and production process efficiency, and reduces energy consumption in glass processing.

Preventive maintenance extends the useful life of machines, while planned service intervals ensure production quality and efficiency. Connecting machines to the Glaston Insight cloud service enables the customer to monitor and report on production in real time, and provides customer support in the event of disruptions with no delays.

Glaston has approximately 4,000 installed and operating machine lines

Customer-oriented R&D

Glaston is the frontrunner in its field, and is known in the glass industry for its high quality. Our position is particularly strong in developing technologically demanding products and we carry out product development in close cooperation with our customers and partners, such as research institutes, universities and other higher education institutions.

At the forefront of our product development are projects and innovations related to increasing automation that facilitate the transition towards fully automated glass processing. In addition to efficiency and reliability, consumption of energy and materials will be optimized and wastage reduced.

Growing demand for solar energy

The increasingly visible consequences of climate change will also affect the glass industry and demand for different kinds of products. The demand for solar energy is growing, and the glass used in solar cells and panels is subject to exacting quality requirements, for example with respect to glass thickness and curved surfaces. Glaston has taken this into account in its product development, and has a wide variety of solar solutions available.

Smart glass entering the market

New glass technologies and glass products providing added value, such as smart glass, are also increasingly entering the market, and the energy-saving potential of smart glass products, for example, is boosting demand for them. Glaston provides consulting and planning services for smart glass and energy glass window production as well as solar energy applications.

Articles

The rise of thin triple insulating glass units: An industry game-changer

The push for better thermal performance in insulating glass units (IGUs) is greater than ever. For example, the 2024 Energy Star guidelines in the U.S. have set...

Read moreGPD 2023 Presentations – Research and development

The Glass Performance Days 2023 conference featured a wealth of cutting-edge research and development sessions. This category is dedicated to showcasing groundbreaking...

Read moreGPD 2023 Presentations – Sustainability and trends

The Glass Performance Days 2023 conference brought forward a compelling array of presentations focused on sustainability and emerging trends within the glass industry....

Read more