When the glasstec trade fair opens its doors in Düsseldorf on 20-23 September 2016, Bystronic glass will present more than 50 years of experience, innovations and trends in insulating glass manufacturing as well as automotive glass pre-processing at Stand A38/E38 in Hall 14 true to the motto “Mission next 50 years“. Two years after celebrating this anniversary milestone with the Swiss Bystronic glass subsidiary in Bützberg, it is now the turn of the subsidiary in Neuhausen-Hamberg (Baden-Württemberg, Germany): Here, machines and plants for the manufacturing of insulating glass have been developed, manufactured and shipped across the world since 1966. This landmark achievement is being celebrated during a daily Happy Hour on the trade fair stand, which will be held between 5.00 p.m. and 6.00 p.m. where regional specialities will be served.

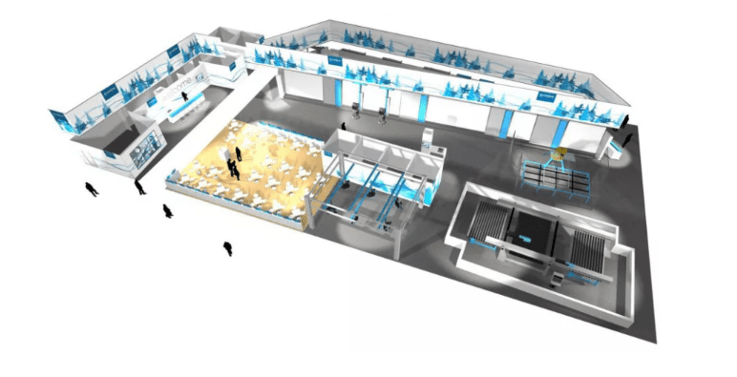

Bystronic glass will present innovative glass processing solutions for the architectural and automotive glass industries in over 1,200 square metres of exhibition space. A number of moderated, live machinery presentations will take place every day to provide the visitors with an in-depth view of the fascinating technologies. Cooperation partner Hegla will again be on the neighbouring stand, enabling the customers to easily enter into discussions with experts from both of the companies.

Insulating glass manufacturing – the customers’ choice

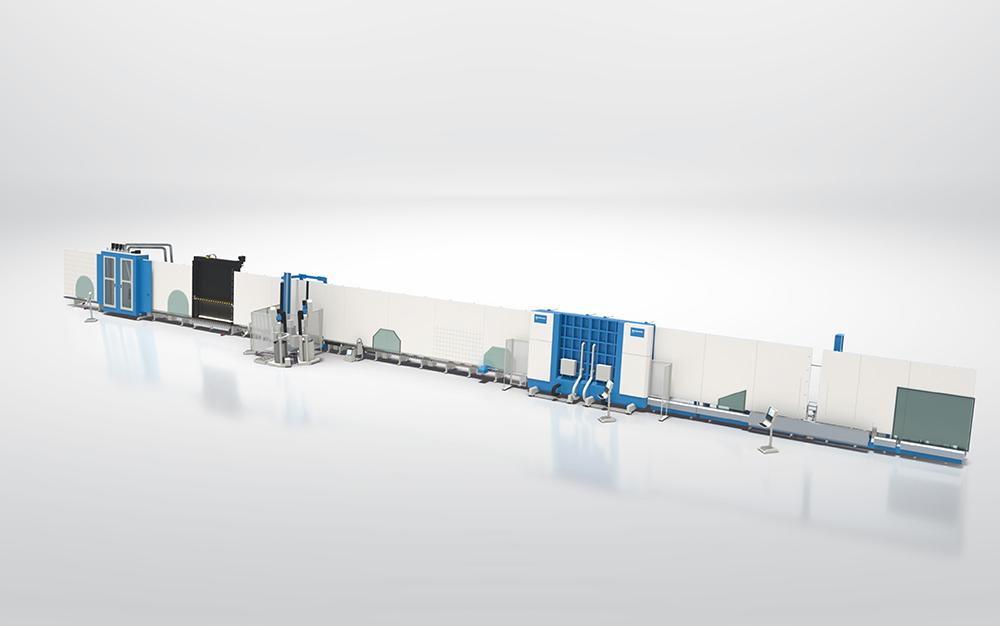

Not one, but two insulating glass lines will be in action on the Bystronic glass stand this year. The B’VARIO TPS and the B’COMFORT will be working back to back:

Within the stand interior, the B’VARIO TPS will demonstrate the flexibility and possibilities of insulating glass manufacturing. The line that can be configured according to specifications will prove its unique diversity, offering a customised production solution for all types of orders.

The use of the thermoplastic spacer TPS® further establishes how the production mix can be manufactured on a single line – without the need for external frame production or separating orders into standard and specialized batches. The insulating glass line is complemented by the newly developed finisher, which is an optional machine that makes the patented bevel joint invisible. In the tried and tested standard version, the bevel joint does not require any thermal-mechanical reworking – it is gastight. The use of the finisher allows customers the option of smoothing the TPS® bevel joint if desired, resulting in an aesthetically improved product. After processing, the thermoplastic spacer retains its form and density. The processing of shapes using the finisher is also possible. The newly developed machine can be easily integrated in existing insulating glass production lines without requiring additional space.

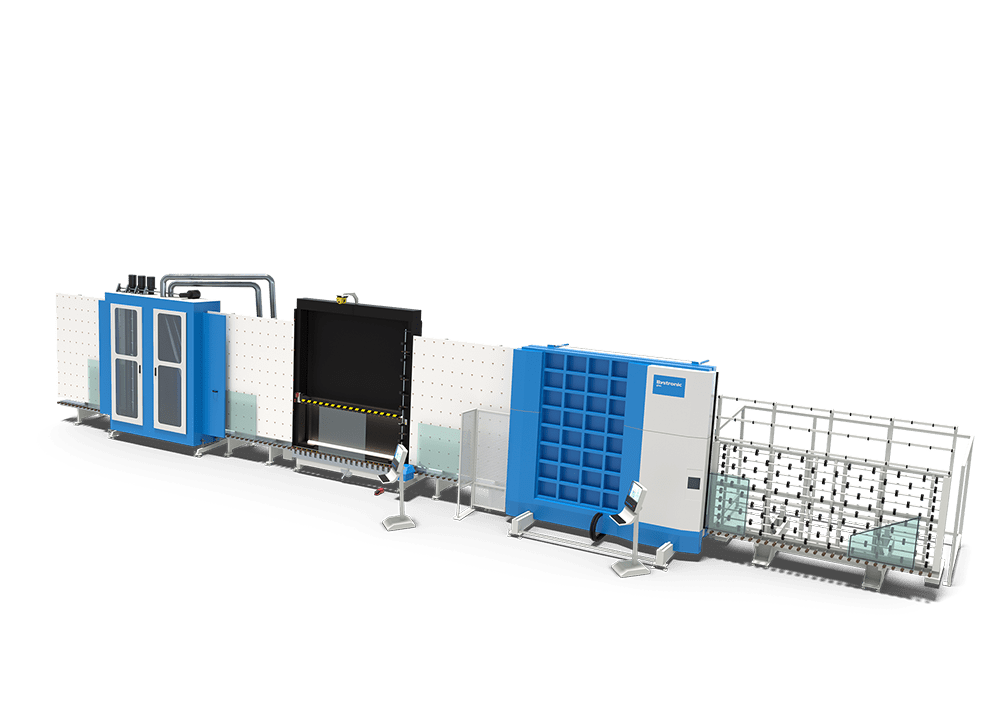

The B’COMFORT on the edge of the stand is a start-up solution for use in automated insulating glass manufacturing processes. In addition to proven Bystronic glass quality and reliability, it is impressive due to low investment costs, a compact unit layout, individual expansion possibilities and high productivity capabilities.

At the trade fair stand it will be presented together with the optional eco’sealer sealing robot. This is the economical solution for the automated insulated glass sealing, and is available in a number of options with numerous expansion possibilities.