FLACHGLAS Wernberg GmbH is one of Europe´s leading glass processors and has been located in the German town of Wernberg since 1938. With more than 600 employees the company manufactures insulating glass, automotive glazing, laminated glass and tempered glass for use in facades, interiors and motor vehicles. The insulating glass units are manufactured on one of the four Bystronic glass lines. Amongst others, that FLACHGLAS Wernberg GmbH has installed in the 9000 m² insulating glass production hall, in order to complement its portfolio.

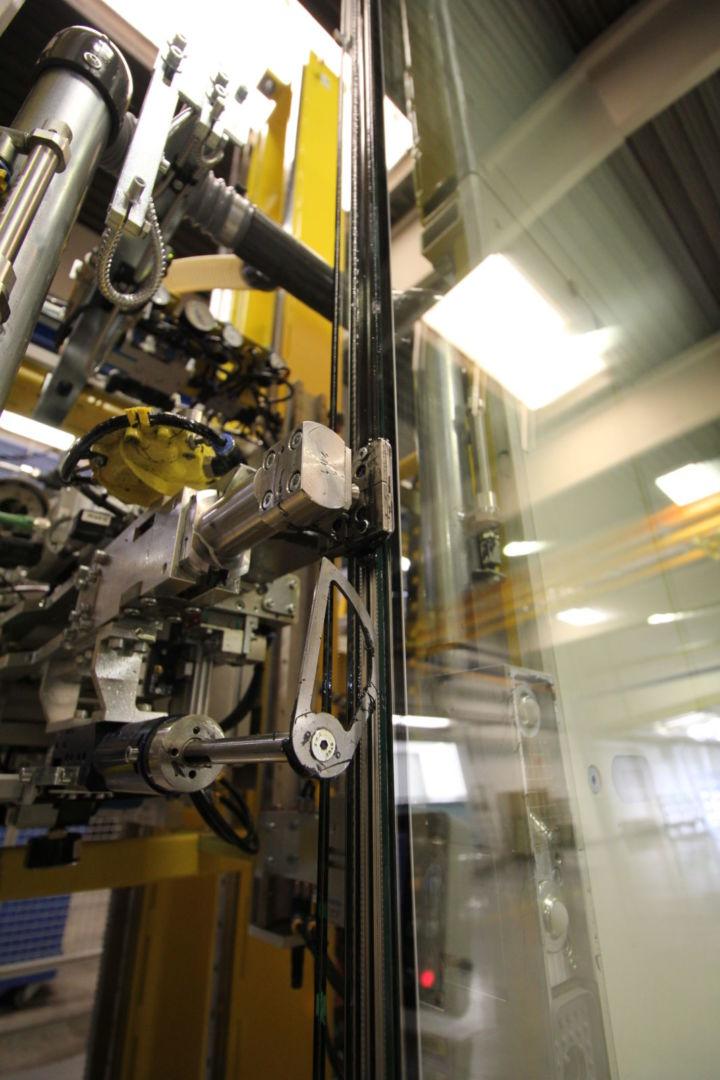

The cooperation between FLACHGLAS Wernberg GmbH and Bystronic glass goes back to the early eighties. This was when the former Lenhardt Maschinenbau GmbH (now Bystronic Lenhardt GmbH) developed the first sealing robots. Despite months of tests being run, company founder Karl Lenhardt, was not satisfied with the sealing quality until employees at FLACHGLAS Wernberg GmbH had provided decisive information necessary on the nozzle shaping which resulted in a design that is still in use today. The speed ‘sealer sealing robot that is the top of the Bystronic glass model range puts in another appearance in the new FLACHGLAS Wernberg GmbH B’JUMBO insulating glass line which was installed as recently as only a few weeks ago. “The sealing robot is first class! The dual circulation provides a perfect sealing quality when sealing triple I.G. units”, said Kai Klinger, Project Manager at FLACHGLAS Wernberg GmbH.

Opting for Bystronic glass

The B’JUMBO insulating glass line enables the I.G. manufacturer to produce its Jumbo glazing with a dimension of 3,210 x 6,000 mm faster and with an even better quality. “It soon became clear at the first meeting with FLACHGLAS Wernberg that not only were demands being placed on the large-dimensioned line, but also on the service, both during and after sales,” said Tobias Schweigert, Project Manager at Bystronic glass.

“Not only was the price-performance ratio of the B’JUMBO best; as a customer in such a project, priority must also be given to the reliability of the supplier. The Service division has to function and react fast. This works extremely well with all of our Bystronic glass lines, so we have a certain amount of basic trust in the new line, and as has been shown, this was not misplaced“, added Kai Klinger. The FLACHGLAS Wernberg GmbH team had already familiarised themselves with the new line at the Bystronic glass site in Neuhausen-Hamberg some months previously. “We had convinced ourselves about the user-friendliness of the line on site whilst also being able to ask some questions in advance. Only three weeks passed between our taking delivery and its complete integration where we could use without any queries or reservations“, explained Kai Klinger.

Working with the B’JUMBO

The B’JUMBO complements the existing plants at FLACHGLAS Wernberg GmbH, enabling excellent quality, global orders to be manufactured. “Working with the B’JUMBO is very easy. As an active global glass supplier, it is important that we are able to accommodate the wishes of our customers. Whether for certain packaging specifications of the installation system concerned, or for orders of bulletproof glass in an I.G. unit, with the B’JUMBO, the implementation of this project is no problem whatsoever”, said a satisfied Kai Klinger.

Project Managers responsible, Kai Klinger and Tobias Schweigert are looking forward to a continued very successful cooperation between FLACHGLAS Wernberg GmbH and Bystronic glass.