TPS® (Thermo Plastic Spacer) will once again be the focus of the Bystronic glass presentation at this year’s Glassbuild America from 17 to 19 September 2019 in Atlanta. Bystronic glass is the inventor of this «warm edge» technology and launched this system in 1994. This is the Original with more than 100 installed TPS® I.G. manufacturing lines worldwide.

TPS® has also been the most successful insulating glass system in the USA in recent years and conquered the American residential insulating glass market. Bystronic glass once again reinforces its image as a market leader of future-oriented technologies for the efficient processing of architectural and automotive glass.

Especially in the residential insulating glass market, the challenges for the glass producers are very high because they cannot process the manufactured insulating glass units so quickly due to the long curing process. The combination of Thermo Plastic Spacer TPS® and hotmelt sealing material offers the I.G. manufacturer a much faster curing process and thus much faster handling of the I.G. units after sealing. This leads to a simplified logistics of the finished I.G. units and a remarkable reduction of requested storage space.

A major advantage of TPS® is its production flexibility: the direct application of the thermo plastic spacer onto the glass lite significantly simplifies the processes for I.G. manufacturers.

The spacer width between the lites can be varied fully-automatically for each I.G. unit during the production process. The respectively required spacer – whether rectangular or shaped format – is always available and is applied as a bead out of a drum. The storage of different spacer profiles and connectors is no longer necessary. Separate production processes are no longer needed for sawing, bending, connecting, desiccant filling and butyl-coating.

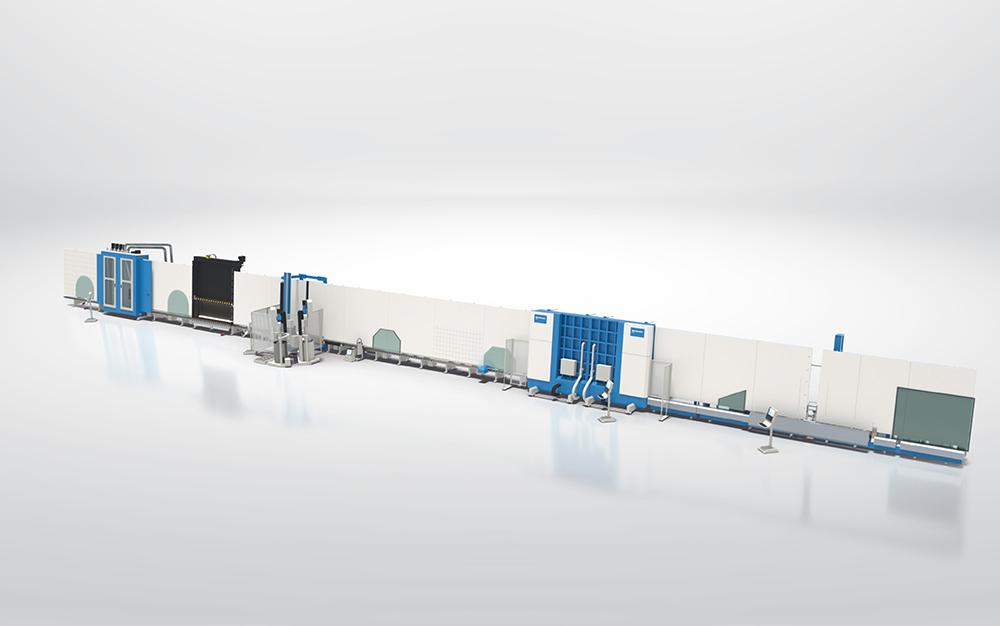

Thus, the entire production mix can be manufactured on one line on the various Bystronic glass TPS® insulating glass production lines. The insulating glass manufacturer can choose from the following system solutions for this purpose:

- B’VARIO TPS® – the individually configurable I.G. manufacturing line

- B’SPEED TPS® – the fast system solution with shortest cycle times

- B’JUMBO TPS® – the I.G. line for max. glass sizes up to 9 m length

The patented, gas-tight bevel joint of TPS® I.G. units has been proven a million times over and does not require any thermal-mechanical reworking. Irrespective of radii, small or large spaces between the lites, this seal always works and is the distinguishing feature of the TPS® edge seal.