Consolidated Glass Corporation, U.S.A.

Reference - Americas

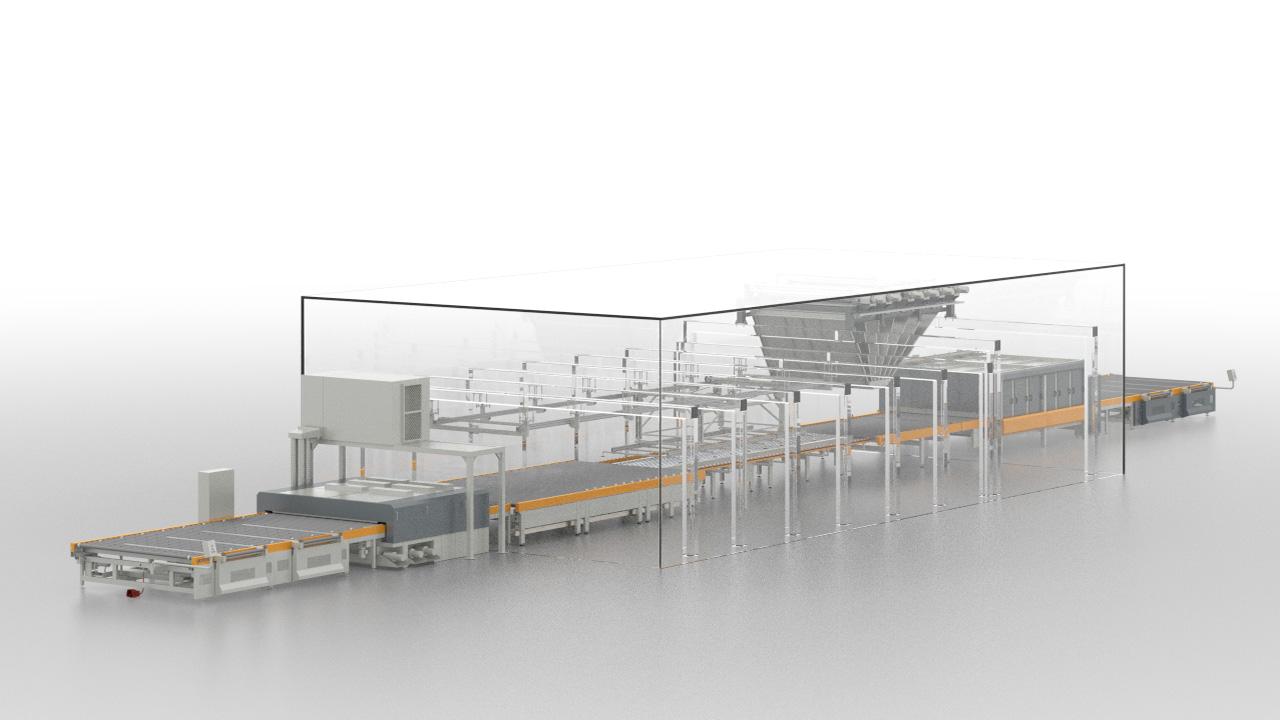

Opening up new opportunities with laminated glass

“We saw the move into laminating glass as an exciting opportunity to explore. It gives us an open door to many new areas, such as security, acoustic and decorative glass. After thoroughly reviewing six lines, we chose Glaston’s ProL lamination thanks to its convection heating and simplicity,” say Consolidated Glass Corporation’s Brad Bartley, General Manager, and Lindsey Merryman, Lamination Line Program Manager.

Consolidated Glass Corporation is no newcomer to diamond-standard interior glass nor making larger transitions to stay ahead of the game. Now being led by the founding family’s fifth-generation president, the company started in 1967 in New Castle, Pennsylvania, fabricating the then fashionable jalousie doors and windows formed with multiple parallel panes of glass. It made a significant expansion in 1994 with its first tempering furnace to supply store fixtures, high-end shower doors and enclosures.

In 2015, Consolidated Glass purchased its second tempering line, a Glaston RC Series, to be able to keep up its outstanding five- to ten-day lead times and push into the lucrative office partition market.

The same spirit of growth and expansion into new glass processing areas led the company to venture into laminated glass in 2021. This meant a new 15,000 sq. ft. building and automated lamination line.

“We reviewed six different lines, comparing price and performance,” Brad recalls. “We were familiar with Glaston’s background and knew the technology they bring to the tempering world. That was important to us.” But what caught his attention most was the convection heating system used on the ProL line as opposed to the infrared (IR) heating systems that most competitors use.

“For me, just the simplicity was impressive. And when you’re investing that much in new technology, you want to know that the supplier is highly experienced in that area. I also spoke with close friends in the industry who praised Glaston’s lamination technology.,”

Similar references

Pilkington Automotive Finland, Finland

#automotive glass #automotiveindustry #CNC #CNC96 #lifecycleservices #mobility #reference #upgrades

“We decided to extend the lifetime of our Bystronic (now Glaston) automotive glass cutting equipment with a Glaston CNC96 upgrade kit and ensure that we can continue to get spare parts,” says Matti Säynäväjärvi, Technical Services Group Leader, Pilkington Automotive Finland Oy, Laitila plant.

Read moreViridian Glass, Australia

#architectural #automation #COMFORT #glass quality #IG unit #insulating glass #reference

As building regulations require more energy-efficient glass, Viridian Glass has stepped up its game. Purchasing Glaston’s COMFORT BOX IG manufacturing line enables its Woodville plant in Adelaide to meet burgeoning demands with visibly better quality and shorter lead times. “High quality insulated glass is the future in Australia,” says, National Operational Excellence Manager, Tarun Bhatia at Viridian Glass.

Read moreAGP, New Zealand

#architectural #automation #autopilot #digitalization #FC Series #flat glass tempering #reference

“We’re now running with the stability, reliability and consistency we aimed to achieve when we invested in Glaston’s Autopilot,” David Bunting, Managing Director of Architectural Glass Products (AGP), says.

Read moreArticles

Convection technology for flat glass lamination keeps improving

The rising preference for laminated glass, known for its safety features, is driving significant market growth. One notable trend in this market is the increasingly...

Read moreOvercoming interlayer temperature hurdles with the prediction method

Flat glass lamination presents various challenges, one of which is achieving the right temperature for the interlayer to ensure high-quality laminated glass without...

Read moreHow to reduce energy consumption in glass lamination

In our previous blog post, we covered some tips for improving energy efficiency in tempering. This time, let’s turn to glass lamination. Typically, the lamination...

Read more