At this year’s China Glass exhibition from 19th – 22nd April 2018 in Shanghai Bystronic glass will present again future-oriented technologies for trend-setting and efficient processing of architectural, automotive and thin glass.

B’CHAMP (Automotive and thin glass processing)

Profitability in automotive glass pre-processing or thin glass production will be redefined.

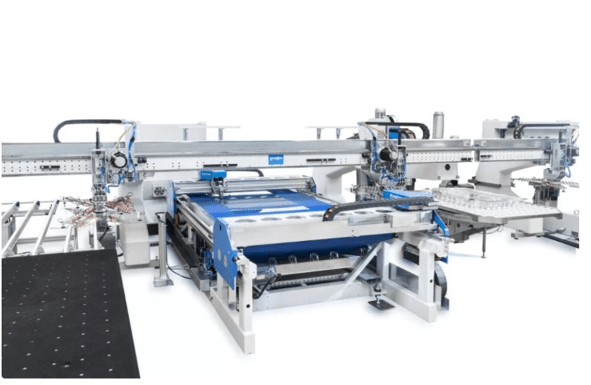

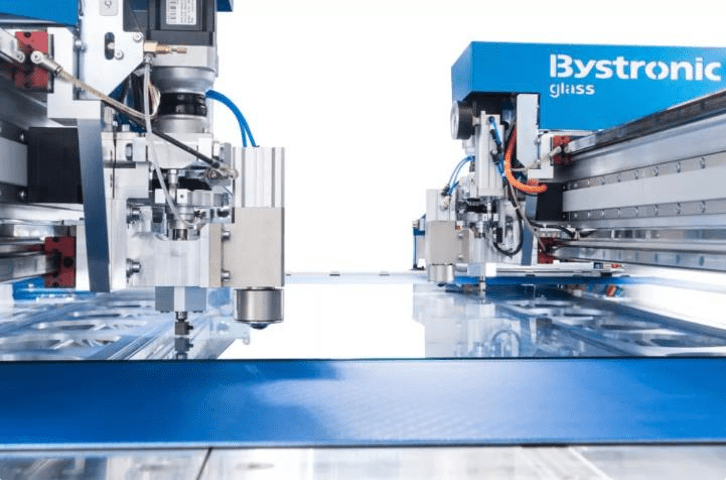

As highlight of the exhibits Bystronic glass will present the B’CHAMP WS – a variant of the new machine generation. The optimized functions of this new B’CHAMP generation enables automotive glass or thin glass producers to enhance the efficiency in their daily production. B’CHAMP installations enable quick and precise cutting, breaking, grinding and drilling of automotive glass or thin glass down to 0.4 mm glass thickness.

By optimizing the key components for the glass processing in a linear manner, space is saved through ingenuity. This leads to a reduced footprint of up to 50 %, a transparent and continuous material flow, a simple installation, improved maintenance possibilities and specified plant configurations for individual glass products, e.g. quarter lites, side lites and windshields.

The improved accessibility to the key components and the innovative software-based support dramatically improves changeover times. For glass producers this means shorter changeover times when changing the model, simplified maintenance and highest possible flexibility in connection with the automated single piece production. The reaction-fast software leads to a minimizing of downtimes, while a camera surveillance system will be used for an automatic positioning aid.

The new B’CHAMP machine generation is available in three variants: B’CHAMP WS for the manufacturing of automotive glass windshields, B’CHAMP SL for the production of side lites and B’CHAMP QL for the manufacturing of quarter lites.

Due to the modular design of the B’CHAMP, it enables to combine several cells together or add additional components that are individually adapted to the customers’ specific requirements – from glass loading, to primitive cutting, through to finished pre-processed automotive or thin glass – all in one system.

B’ADVANCE (Insulating glass manufacturing)

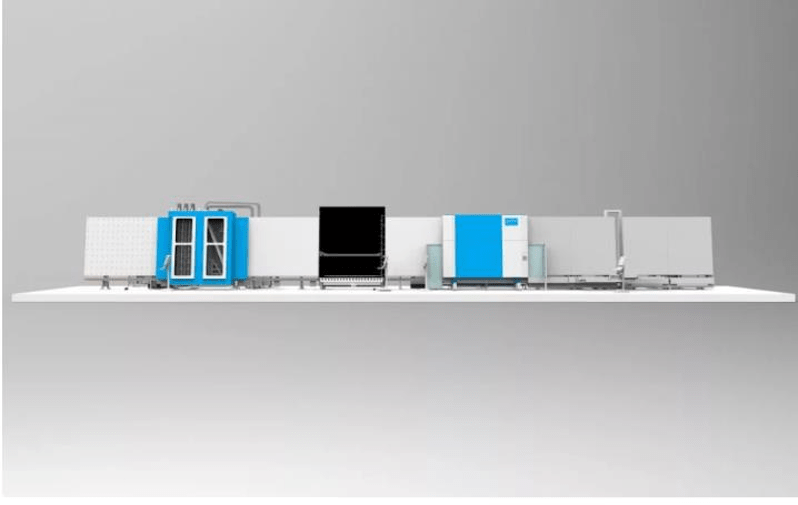

The new I.G. manufacturing line B’ADVANCE will be presented during an Open House Event at the premises of Bystronic Glass Machinery (Shanghai) Co. Ltd. in Jiading District / Shanghai. By joining a shuttle bus service interested customers and prospects are invited to visit the live demonstrations of the B’ADVANCE under production conditions.

The B’ADVANCE is a standardized solution for high quality manufacturing of rectangular or shaped, gas filled I.G. units with low-E glass on one line. The fully equipped I.G. line is engineered and manufactured in Germany. It offers numerous components as standard – like e.g. manufacturing of 3-sided stepped I.G. units, air cushion conveyors instead of roller conveyors or a server based control system including remote support. With the B’ADVANCE the I.G. producers will be able to enhance their flexibility in I.G. manufacturing and to increase their productivity on a next higher level.

B’EASY (Glass handling)

The best-selling Easy-Lift has been inspiring customers from the glass processing industry with its rigid guidance and its own low dead weight since 1998. In recent years, the handling equipment has also gradually established itself with large window manufacturers as it is extremely flexible in terms of frame design, easily meeting their needs.

Service – on hand, wherever our customers are located

Right from the very first minute, Bystronic glass supports its customers during the planning stage. The customer service department is then on-hand all over the world for the delivery of spare parts and on-site support. Maintenance contracts and individual training sessions round off the range of services on offer.