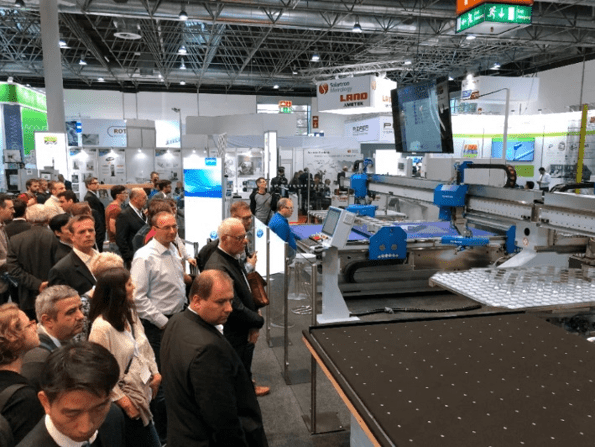

“Join us at the top” was the exhibition motto of Bystronic glass at glasstec 2018 and the show proved very successful with exceedingly positive results achieved. Bystronic glass presented more than 50 years of experience in innovative glass processing solutions for the architectural, automotive and display glass industries in over 1,000 sqm of exhibition space.

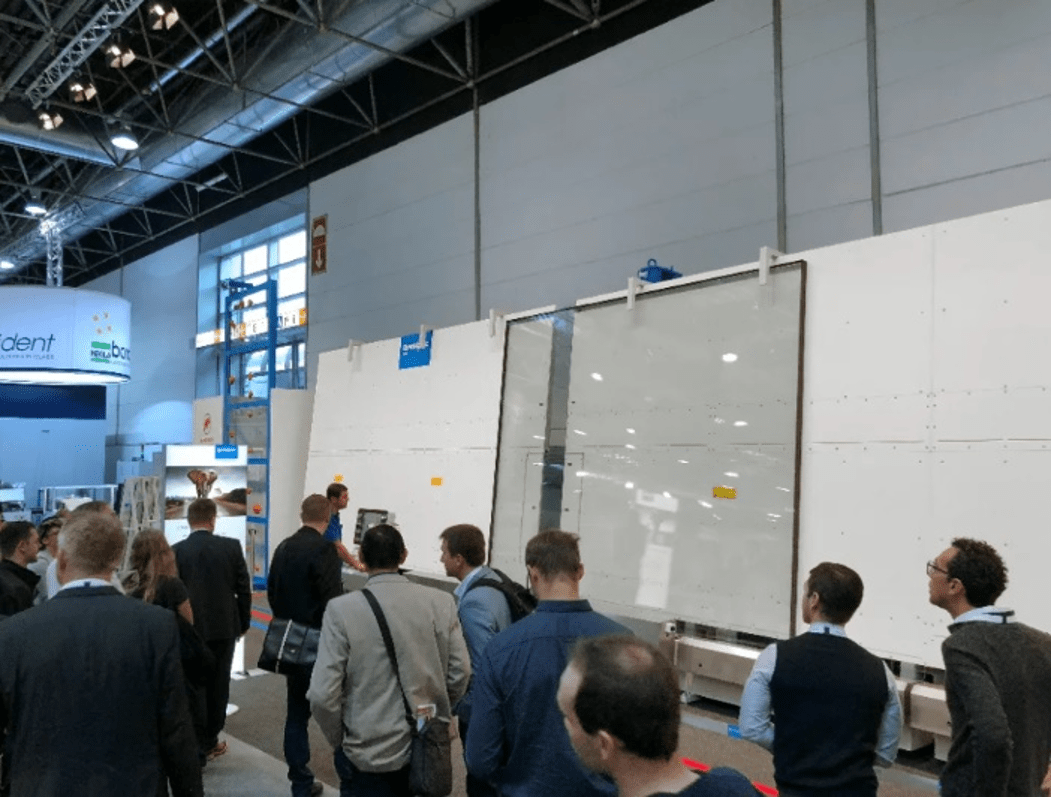

The international biennial event proved the perfect platform to exhibit innovations from the Bystronic glass range, with products including the jumbo’sealer. It can seal even deep spacer setbacks of rectangular and shaped units faster compared to other machines in the market, clearly impressing visitors to the exhibition. With the XXL version, glass sizes up to 18 m in length at a total weight of up to 10 tons can be sealed – and this for up to 4-sided stepped I.G. units.

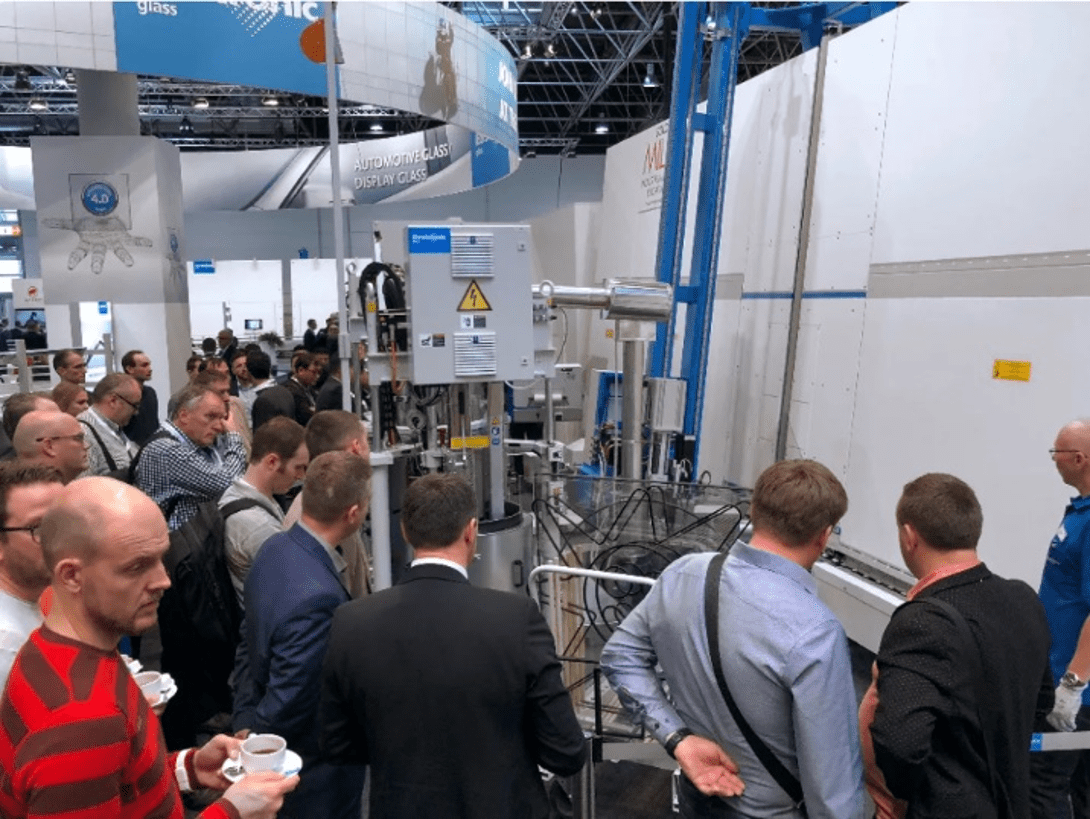

As the original inventors of TPS® Bystronic glass made great headway at glasstec this year with customers looking to invest in ‘warm edge’ technology. Key technical advantages that impressed visitors are its flexibility in the production process and the ability to speed up manufacturing, with fully automatic spacer width change between the lites. The material comes from a drum and is applied as a bead in a proven process, whilst the air-tight bevel joint does not need any thermal-mechanical reworking.

Another exhibit that drew a lot of attention was the new spacerbender MULTI, which has been designed as an economical solution for bending warm edge spacer profiles with heated corners. This created particular interest as aluminium and warm edge hybrid profiles can be processed automatically on this system.

With B’VACOOM Bystronic glass presented a completely new generation of handling equipment for efficient flat glass and plate processing. This newly developed machine generation represents a successful combination of traditional equipment manufacturing and digital transformation, let’s call it Bystronic glass 4.0 in practical use.

In the field of automotive glass Bystronic glass demonstrated B‘CHAMP WS, a complete cell for the pre-processing of windshields. B’CHAMP installations enable fast and precise cutting, breaking, grinding and drilling of automotive or display glass down to 0.4 mm glass thickness.

The event attraction was the 5 metre high glass climbing wall created in cooperation with MAMMUT, another business unit of Conzzeta AG (Switzerland), of which Bystronic glass also belongs. This specially created glass mountain challenge, which was carefully monitored by specialist mountain guides from the MAMMUT Alpine School, proved a tempting focal point at the show for many visitors.

On summing up the event, Peter Nischwitz, Head of Corporate Communications at Bystronic glass commented: “The glasstec 2018 show exceeded our high expectations and our stand was one of the busiest throughout the entire exhibition. This demonstrates to us once again that glasstec has been and continues to remain the most important professional exhibition for us”.

One of the pivotal aspects at the event was the high number of visitors as well as the quality of conversations during the show with leads generated and business deals negotiated.

Dietmar Walz, CSO Bystronic glass, stated: “Our team was able to answer the specific needs of visitors leading to very constructive and positive discussions with them.” He concluded: “glasstec 2018 has given us an excellent framework to build upon and we overachieved our exhibition goals. We noted great interest in our product range, notably among new customers and consequently sold all machinery exhibits at the show. Now we are expecting further new contracts over the coming months.”