Outdated lamination line upgraded with Glaston ProL

Enhancing its flat glass lamination line by replacing outdated components with new technology, Malaysia-based Crystal Safety Glass (CSG) turned an expensive problem into an unexpectedly positive experience. The move was not easy, but it helped bring the processor’s existing line back up to date with an impressive list

of value-added features. For the plant operators, the upgrade lowered the cost of modernizing the existing line and provided less downtime, higher productivity and significant improvements in energy consumption.

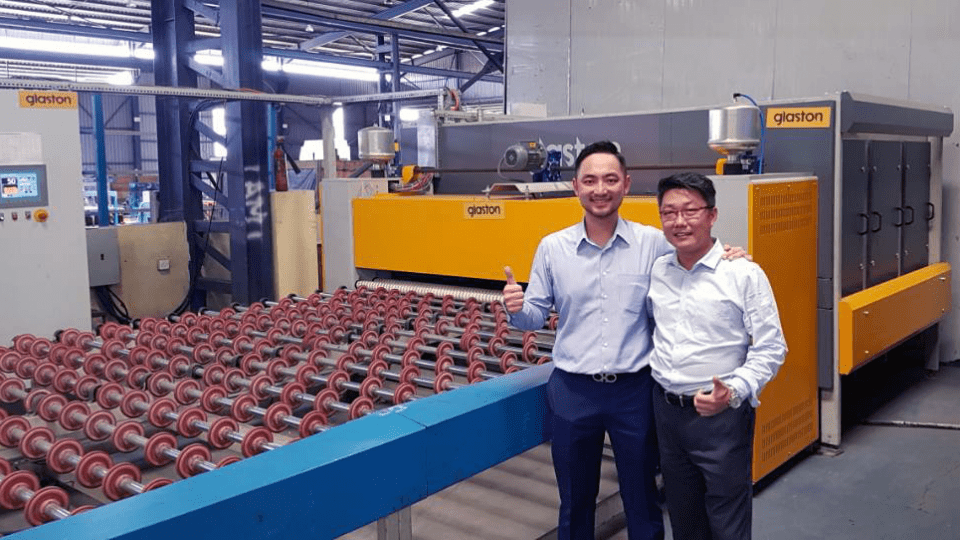

Frank Tan, Group Managing Director at Crystal Safety Glass and his team decided to go with Glaston’s ProL flat glass laminating zone to replace their outmoded pre-pressing unit and heating chamber. Not only is the technology new, but it includes a wide range of features. In particular, the full convection technology of the new ProL seemed ideal for providing much more accurate and optimized heat transfer, therefore enabling consistently high glass quality.

The promise of a quick turnaround also helped. It was essential for CSG to minimize production downtime – with numerous customers expecting orders all

across Asia Pacific. “It took only seven days for Glaston’s installation team to dismantle, install, integrate and commission the new parts,” Frank recalls. “The transition was so smooth, in fact, that it barely interrupted our production schedule.”

A month after the upgrade, the customer reported great performance improvement and even an unexpectedly considerable production increase. “We are really pleased with the results we are seeing now,” Frank comments. “We reached over 90% in capacity increase, which was unexpected and really an impressive figure. The upgrade resolved a lot of our issues and improved our yield significantly.”