Finding a way to truly temper extremely thin glass has posed a challenge to the glass processing industry. Either the solutions have been too cost-prohibitive or then the end glass products have been of sub-par quality. We have now developed a way to harness air flotation technology to temper glass down to 2 mm, allowing it to be used as an economically viable and durable option for a wide range of weight-sensitive applications.

Solar panels drive development of tempered thin glass

One of the most pressing drivers to tackle the thin glass tempering challenge has been the exponential growth in the global solar industry and the need for lightweight, rugged solar panels at a reasonable cost.

The new air flotation technology not only provides a solution to overcome the technical, cost and energy consumption limitations inherent with conventional heat treatment technologies, it also provides a superb end product for various applications where weight and cost are an issue.

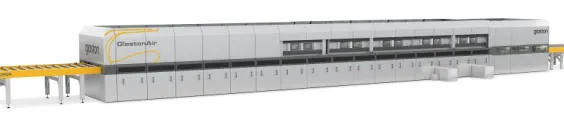

GlastonAir is the fruitful result of this development. The unique air flotation technology allows a higher exit temperature, making it possible to temper thin glass down to 2 mm. The stable bottom heating ensures excellent and consistent end product quality.

We welcome you to learn more at China Glass 2013 in Beijing, China, at GPD Finland 2013 in Tampere, Finland and at MirStekla in Moscow, Russia.