JUMBO & JUMBO XXL

The system solution for maximum requirements

Looking to aim big?

Here are three reasons why Glaston JUMBO and Glaston JUMBO XXL are your best choice

1.

Insulating glass units

up to 600 kg/m

2.

Maximum glass size

3.3 x 18 m

3.

“Green production” with optimum energy efficiency

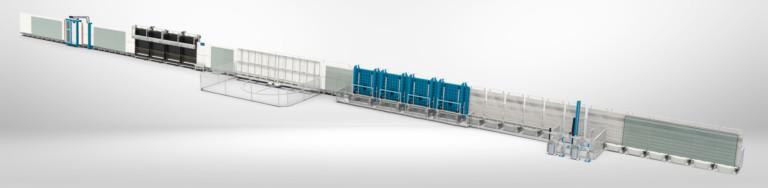

JUMBO & JUMBO XXL

Impressive insulating glass manufacturing in maximum size

Glaston JUMBO and Glaston JUMBO XXL are insulating glass lines specially designed for manufacturing large-sized insulating glass units and façade elements up to 18 m in length.

- Up to 600 kg per running meter with heavy unit capability

- Optimized insulating glass line energy efficiency

Edge deletion of jumbo units in rectangular and shaped formats

Automatic positioning and pressing of the upper frame edge

Automatic turning of coated glass plates up to 12 m in length

Automatic assembling, gas filling and pressing of up to four-sided stepped jumbo units

Continuous sealing of up to four-sided stepped jumbo units with up to 30 mm sealing depth

References

Full Glass, Peru

#architectural #automation #flat glass tempering #glass tempering #glass tempering process #iControL #RC Series #reference #tempered glass

“We are very satisfied with the quality of our new RC Series tempering line and the glass it produces. The Vortex Pro convection control system is excellent. The furnace made by Glaston China is just as well manufactured as the previous furnace we bought from Glaston’s factory in Finland,” says Frank Calderón Gómez, Managing Director at Full Glass in Lima, Peru.

Read moreAGC Interpane, Germany

#architectural #automation #glass processing #IG unit #insulating glass #reference #technology

“I walk through our insulating glass production facility every day with pride,” says Daniel Bruckelt, Production Manager Insulating Glass of AGC Interpane in Plattling, Germany. “Not just because everything is so well organized and structured, but also because Glaston has given us a coherent concept for our unique insulating glass (IG) production. And this is what allows us to remain top-of-mind for challenging world-class projects.”

Read moreEmirates Glass, UAE

#architectural #automation #flat glass tempering #glass tempering #iLooK #Jumbo Series #reference #safety glass #tempered glass

Emirates Glass LLC, one of the leading organizations in the glass industry and a long-time advocate of Glaston technology, continues its journey of innovation and quality enhancement with the installation of the Glaston Jumbo Series flat glass tempering line featuring Vortex Pro convection technology. This investment marks Emirates Glass’s commitment to delivering top-notch architectural glass solutions to the region and far beyond.

Read moreArticles

TPS® – revolutionizing insulating glass production

The production of insulating glass (IG) is undergoing a radical transformation. As long as glass plates keep getting larger and the demand for triple IG continues...

Read moreUnlocking energy efficiency potential: vacuum-insulated glazing for sustainable buildings

Do you know that uplifting existing building stock with high-performance insulating windows will decrease the building sector’s total energy consumption by 40%...

Read more#AskGlaston Insulating Glass Manufacturing Series Episode 2: MULTI’ARRISSER

This is the second video in our #AskGlaston Insulating Glass Manufacturing Series. This time, we will talk about the new glass arrissing machine, MULTI’ARRISSER....

Read more