SPEED

The benchmark in triple and quadruple insulating glass manufacturing using conventional, flexible and TPS® spacers

Looking for the fastest possible insulating glass production?

Here are three reasons why Glaston SPEED is your best choice

1.

Produce triple units in the same time other lines produce double units

2.

Ideally designed work steps

3.

Choose between conventional, flexible or TPS® spacers

Glaston SPEED is a quick insulating glass manufacturing line that produces triple and quadruple units in the fastest possible cycle times. It is available in the following variants:

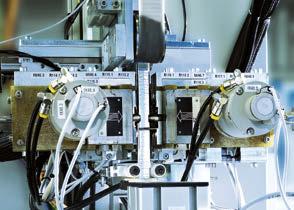

SPEED BOX

Fastest insulating glass manufacturing using conventional spacers

Quick, synchronized gas filling of both spaces between triple insulating glass units

Dynamic quality sealing at the maximum flow rate and highest speed application

Shortest cycle times thanks to parallel filling and transporting operations

Precise, automatic spacer frame butyl coating

SPEED FLEX

Fastest insulating glass manufacturing using flexible spacers from the reel

Twin-head applicator for interruption-free insulating glass production with different spacer widths

Processing of flexible spacers with double-sided polyisobutylene application

SPEED TPS®

Fastest insulating glass manufacturing using TPS®

Direct application of the Thermo Plastic Spacer (TPS®) onto the glass plate. The spacer width can be changed as desired during operation without any time loss

The dual-drum pump system enables completely interruption-free operation. The material drum change takes place during production

Possibility of individual product identification according to local regulations.

References

Glas Herzog, Germany

#architectural #automation #insulating glass #reference #SPEED

“We have a great deal of confidence in our supplier,” says Andreas Herzog, Sr., Managing Director of Glas Herzog. “Our cooperation with former Bystronic glass – and now Glaston – is just as you would want it to be as a customer. In fact, we’re one of their oldest customers – 44 years and counting.”

Read moreFLACHGLAS, Germany

#flat glass laminating #glass processing #glass quality #laminated glass #laminating #ProL #ProL-zone #quality control #reference #safety glass #upgrades

At FLACHGLAS, a culture of operational excellence fuels continuous modernizations. “The latest Glaston ProL upgrade for our 50-year-old lamination line has helped us raise performance, save energy and automate production with the push of a button,” says Martin Geiss, Technical Manager at FLACHGLAS Wernberg.

Read moreFull Glass, Peru

#architectural #automation #flat glass tempering #glass tempering #glass tempering process #iControL #RC Series #reference #tempered glass

“We are very satisfied with the quality of our new RC Series tempering line and the glass it produces. The Vortex Pro convection control system is excellent. The furnace made by Glaston China is just as well manufactured as the previous furnace we bought from Glaston’s factory in Finland,” says Frank Calderón Gómez, Managing Director at Full Glass in Lima, Peru.

Read moreArticles

GPD 2023 Presentations – Sustainability and trends

The Glass Performance Days 2023 conference brought forward a compelling array of presentations focused on sustainability and emerging trends within the glass industry....

Read moreGPD 2023 Presentations – Architectural glass

The Glass Performance Days 2023 conference has once again brought together a wealth of knowledge and innovation from the leading minds in the glass industry. We...

Read moreTPS® – revolutionizing insulating glass production

The production of insulating glass (IG) is undergoing a radical transformation. As long as glass plates keep getting larger and the demand for triple IG continues...

Read more