Armour Sealed Units Ltd., UK

Reference - Europe

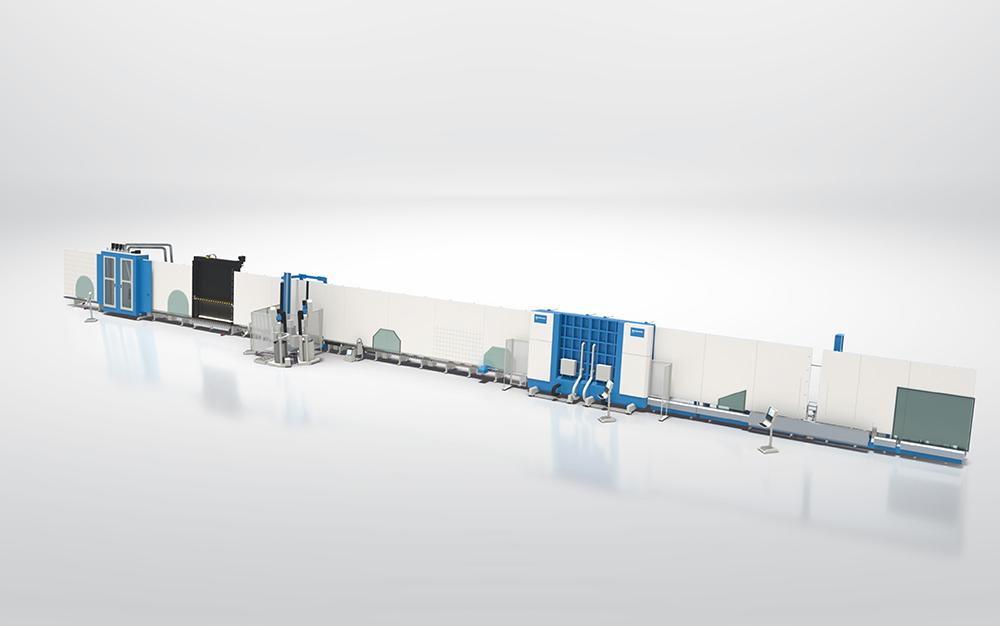

Tailor-made IG solution for Armour Sealed Units Ltd. in Bristol

Those who believe that insulating glass (IG) manufacturers are always located on industrial estates on the outskirts of towns are very much mistaken. The route to Armour Sealed Units passes through the centre of a quiet residential area in Bristol and ends in a cul-de-sac. An older building, measuring almost 250 square metres with the white-red company logo can be found at the end of this cul-de-sac. Company founder and owner Peter Crowley explains how his desire for an insulating glass line in the small factory was fulfilled thanks to Bystronic glass and tells of the challenges that had to be overcome.

Peter Crowley founded Armour Sealed Units Ltd. in 1983 and, since then, has been able to acquire numerous regular customers from the surrounding area for his insulating glass. Two years later, the family company – his son is the head of production and his wife takes care of the office work – moved to the current location. Initially, the insulating glass production was largely performed on a manual basis. Later, it was only the sealing that was performed manually. “For a long time, I could not imagine that a complete insulating glass line including a sealing robot would fit in our small factory”, explains Peter. However, the entrepreneur was fully aware that he needed to invest in his production facility and modernise the old machinery in order to remain competitive and continue to be able to produce premium products that meet the current legal requirements.

“Bystronic glass was the only provider that was able to offer me a fully-equipped insulating glass line for my factory that only measures about 20 metres in length.What most impressed me was the fact that they did not want to force a standard solution full of compromises upon us, they fully recognised our production needs and the on-site conditions.”

Similar references

Pavle, Serbia

#architectural #automation #flat glass tempering #glass tempering #iControL #Jumbo Series #reference #safety glass #tempered glass

“With our Glaston Jumbo furnace and insulating line, we can now produce the biggest IG units in the Balkans, and our business is taking off internationally. The line helps us serve architects who want ever-larger, top-quality windows for offices, schools and even shopping malls with glass sizes up to 3.5 meters or more,” says Jelena Blagojevic, Marketing Manager of Pavle.

Read moreFLACHGLAS, Germany

#flat glass laminating #glass processing #glass quality #laminated glass #laminating #ProL #ProL-zone #quality control #reference #safety glass #upgrades

At FLACHGLAS, a culture of operational excellence fuels continuous modernizations. “The latest Glaston ProL upgrade for our 50-year-old lamination line has helped us raise performance, save energy and automate production with the push of a button,” says Martin Geiss, Technical Manager at FLACHGLAS Wernberg.

Read moreFull Glass, Peru

#architectural #automation #flat glass tempering #glass tempering #glass tempering process #iControL #RC Series #reference #tempered glass

“We are very satisfied with the quality of our new RC Series tempering line and the glass it produces. The Vortex Pro convection control system is excellent. The furnace made by Glaston China is just as well manufactured as the previous furnace we bought from Glaston’s factory in Finland,” says Frank Calderón Gómez, Managing Director at Full Glass in Lima, Peru.

Read moreArticles

The rise of thin triple insulating glass units: An industry game-changer

The push for better thermal performance in insulating glass units (IGUs) is greater than ever. For example, the 2024 Energy Star guidelines in the U.S. have set...

Read moreWhat users say about tempering process Autopilot

The demand for higher output quality and yield in flat glass tempering is rising quickly, yet at the same time, the availability of experienced operators is declining....

Read moreGPD 2023 Presentations – Case studies

Explore a variety of practical insights from industry experts through detailed case studies covered during the Glass Performance Days 2023 conference. These sessions...

Read more