Fraunhofer ISE, Germany

Reference - Europe

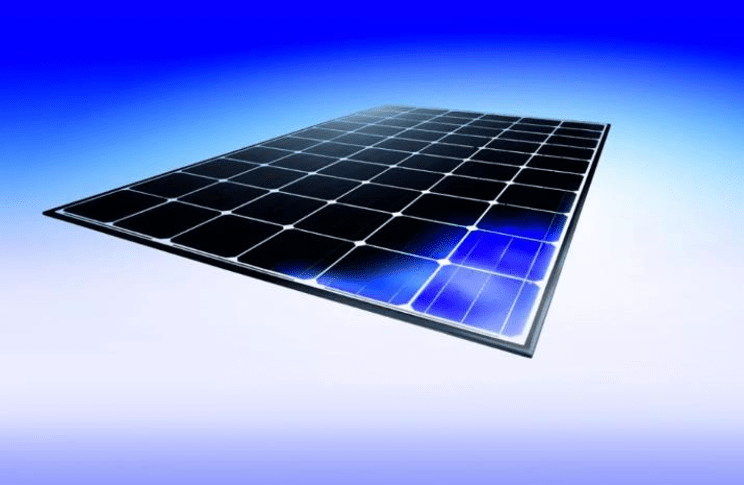

70 TPedge modules on the Fraunhofer ISE façade in Freiburg

It is only recently that 70 TPedge photovoltaic modules have adorned the external façade of Fraunhofer Institute for Solar Energy Systems (ISE) laboratory in Freiburg, Germany. These modules are a joint development between Bystronic glass and the Fraunhofer ISE. Ten of these modules were already integrated into the façade in 2013 and still they continue to work reliably. A further 60 modules will now follow.

The TPedge modules are the result of a long lasting project that has been running for several years with the objective of finding a less expensive, faster and more simple PV module production.

Instead of taking the necessary 12 minutes to produce a PV module when adopting the standard process, a TPedge module can be produced within cycle times of less than one minute. “A modified TPS® insulating glass line along with a robot can accurately position the adhesive points with exceptional precision in terms of millimeters. This enables all insulating glass manufacturers to now be able to produce TPedge modules, and therefore expand their market“, explained Tobias Neff, Solar Product Manager at Bystronic glass.

“TPS insulating glass has been tried and tested on a global scale, which gives tremendous advantages, as it has proven itself resistant in a variety of temperatures and diverse weather conditions.”

Similar references

FLACHGLAS, Germany

#flat glass laminating #glass processing #glass quality #laminated glass #laminating #ProL #ProL-zone #quality control #reference #safety glass #upgrades

At FLACHGLAS, a culture of operational excellence fuels continuous modernizations. “The latest Glaston ProL upgrade for our 50-year-old lamination line has helped us raise performance, save energy and automate production with the push of a button,” says Martin Geiss, Technical Manager at FLACHGLAS Wernberg.

Read moreFull Glass, Peru

#architectural #automation #flat glass tempering #glass tempering #glass tempering process #iControL #RC Series #reference #tempered glass

“We are very satisfied with the quality of our new RC Series tempering line and the glass it produces. The Vortex Pro convection control system is excellent. The furnace made by Glaston China is just as well manufactured as the previous furnace we bought from Glaston’s factory in Finland,” says Frank Calderón Gómez, Managing Director at Full Glass in Lima, Peru.

Read moreAGC Interpane, Germany

#architectural #automation #glass processing #IG unit #insulating glass #reference #technology

“I walk through our insulating glass production facility every day with pride,” says Daniel Bruckelt, Production Manager Insulating Glass of AGC Interpane in Plattling, Germany. “Not just because everything is so well organized and structured, but also because Glaston has given us a coherent concept for our unique insulating glass (IG) production. And this is what allows us to remain top-of-mind for challenging world-class projects.”

Read moreArticles

GPD 2023 Presentations – Sustainability and trends

The Glass Performance Days 2023 conference brought forward a compelling array of presentations focused on sustainability and emerging trends within the glass industry....

Read moreGPD 2023 Presentations – Glass processing technologies

The Glass Performance Days 2023 conference showcased a range of pioneering presentations on glass processing technologies, bringing together industry leaders and...

Read moreGPD 2023 Presentations – Architectural glass

The Glass Performance Days 2023 conference has once again brought together a wealth of knowledge and innovation from the leading minds in the glass industry. We...

Read more