AGC Interpane, Germany

Reference - Europe

Tailoring a unique spacer application approach for world-class insulating glass

“I walk through our insulating glass production facility every day with pride,” says Daniel Bruckelt, Production Manager Insulating Glass of AGC Interpane in Plattling, Germany. “Not just because everything is so well organized and structured, but also because Glaston has given us a coherent concept for our unique insulating glass (IG) production. And this is what allows us to remain top-of-mind for challenging world-class projects.”

AGC Interpane’s Plattling plant, located at the gateway to the Bavarian Forest, produces high-quality semi-finished glass products and insulating glass. Since 2012, AGC Interpane has been coating glass up to 18 m x 3.21 m. This extra-long glass can be coated with a variety of solar control layers or iplus thermal insulation layers.

AGC Interpane’s Plattling site specializes in processing logistically complex, fixed-size insulating glass orders. The company’s magnetron sputtering system, a physical vapor deposition method that produces thin films and coating, differentiates the company from its competition. The system allows AGC Interpane to offer high-quality façade glass from a single source.

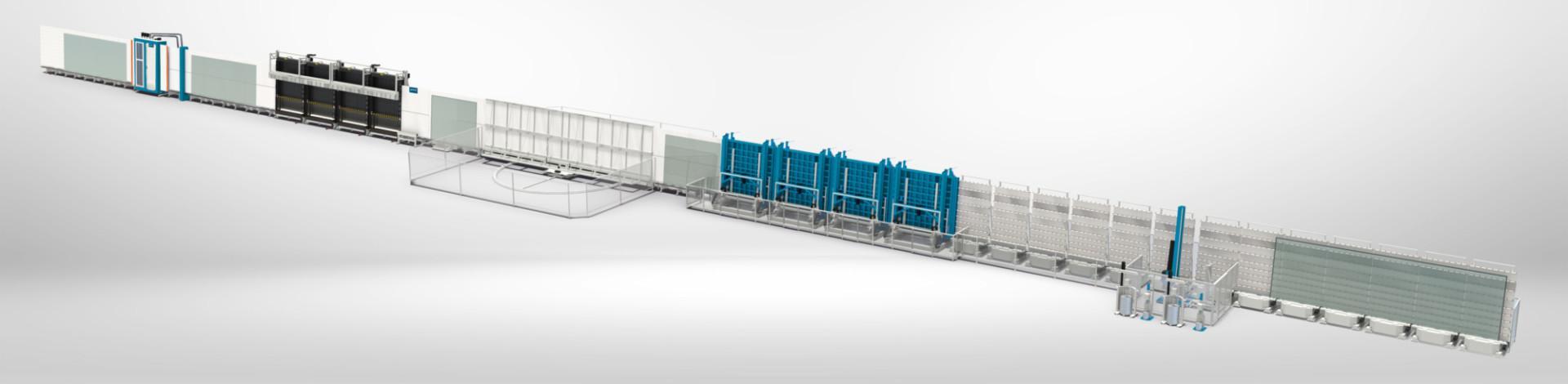

AGC Interpane has been a long-term customer of Glaston and the earlier brands that now belong to the Glaston family. The company currently has three Glaston insulating glass lines and one Glaston tempering line. The most recent addition, the Glaston JUMBO XXL FLEX line, was customized for AGC Interpane. The line was ordered in 2021 and commissioned in April 2022. It allows AGC Interpane to automatically produce jumbo formats up to 3.3 x 6 m.

Earlier, these could only be produced semi-automatically or with additional manual effort. The line includes standard components for edge deletion, glass cleaning and glass inspection as well as several specially engineered features.

“Glaston has given AGC Interpane a unique constellation in the spacer application sector. We are the only ones in the world to have this configuration. The UNIT’ASSEMBLER allows us to process special shapes and fill them automatically with gas. The SPEED’SEALER has eliminated any bottleneck at the end of the line. This means that it is now possible to automatically produce large insulating glass units weighing up to 600 kg / m.”

Similar references

Pavle, Serbia

#architectural #automation #flat glass tempering #glass tempering #iControL #Jumbo Series #reference #safety glass #tempered glass

“With our Glaston Jumbo furnace and insulating line, we can now produce the biggest IG units in the Balkans, and our business is taking off internationally. The line helps us serve architects who want ever-larger, top-quality windows for offices, schools and even shopping malls with glass sizes up to 3.5 meters or more,” says Jelena Blagojevic, Marketing Manager of Pavle.

Read moreFLACHGLAS, Germany

#flat glass laminating #glass processing #glass quality #laminated glass #laminating #ProL #ProL-zone #quality control #reference #safety glass #upgrades

At FLACHGLAS, a culture of operational excellence fuels continuous modernizations. “The latest Glaston ProL upgrade for our 50-year-old lamination line has helped us raise performance, save energy and automate production with the push of a button,” says Martin Geiss, Technical Manager at FLACHGLAS Wernberg.

Read moreFull Glass, Peru

#architectural #automation #flat glass tempering #glass tempering #glass tempering process #iControL #RC Series #reference #tempered glass

“We are very satisfied with the quality of our new RC Series tempering line and the glass it produces. The Vortex Pro convection control system is excellent. The furnace made by Glaston China is just as well manufactured as the previous furnace we bought from Glaston’s factory in Finland,” says Frank Calderón Gómez, Managing Director at Full Glass in Lima, Peru.

Read moreArticles

The rise of thin triple insulating glass units: An industry game-changer

The push for better thermal performance in insulating glass units (IGUs) is greater than ever. For example, the 2024 Energy Star guidelines in the U.S. have set...

Read moreWhat users say about tempering process Autopilot

The demand for higher output quality and yield in flat glass tempering is rising quickly, yet at the same time, the availability of experienced operators is declining....

Read moreGPD 2023 Presentations – Case studies

Explore a variety of practical insights from industry experts through detailed case studies covered during the Glass Performance Days 2023 conference. These sessions...

Read more