Independent Glass, UK

Reference - Europe

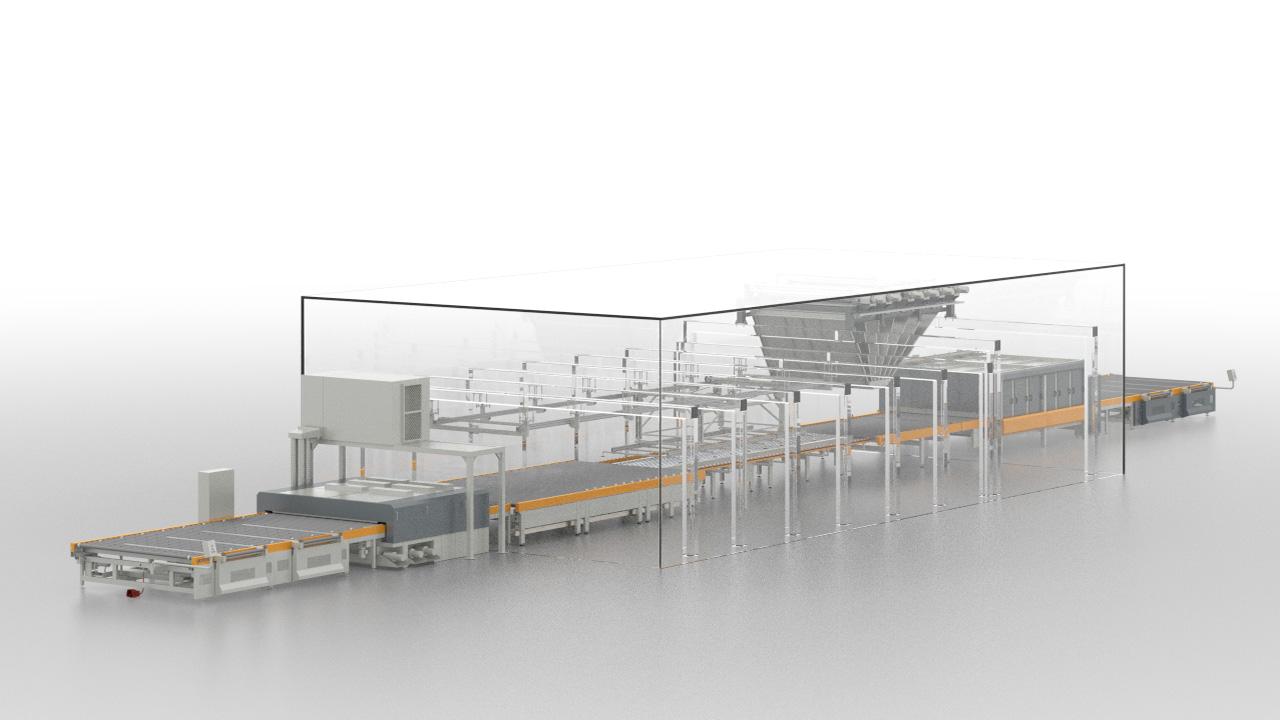

Independent Glass upgrades lamination with Glaston ProL-zone

“Integration is always the biggest risk when combining sections from two different manufacturers,” says Andrew Smith, Group Manufacturing Manager at Independent Glass. Speaking about his company’s recent upgrade, he continues: “The entire upgrade project with Glaston’s ProL-zone went very smoothly. We’ve now been able to increase our laminating capacity, run the line with flexibility and ease – and lower our energy consumption.”

Glaston is no stranger to Independent Glass. For over a quarter of a century, the laminating and glass toughening company has been investing in lines from Glaston for its three sites in Glasgow, Scotland, and the one in Mansfield, England.

In late 2016, the company decided to upgrade the lamination oven at its Mansfield location – which focuses on structural glazing, architectural glass and balustrades – to better serve the growing needs of their market.

“The first question was whether to retrofit the oven or to upgrade,” Andrew explains. “We looked at several options alongside of Glaston, but in the end, we decided to go with the advantages the ProL technology could offer, rather than an infrared retrofit solution.”

Integration of the new machine was a key concern for Andrew and his team, since the existing laminating line was from a different manufacturer. So he went to see another ProL-zone in Denmark with Glaston’s UK representative Steve Brammer. The trip offered exactly what Andrew wanted to see: Glaston’s ProLzone working seamlessly with another manufacturer’s laminating line.

Andrew says that his company has been receiving benefits from the upgraded machine since day one. The machine has been operating in an extremely reliable manner. The new line has achieved increased capacity, greater flexibility and ease of running.

“The ProL now has increased our yield considerably, which means increased efficiency. This was one of our main objectives for the investment. Now we have the competence again to compete successfully in lamination.”

Similar references

FLACHGLAS, Germany

#flat glass laminating #glass processing #glass quality #laminated glass #laminating #ProL #ProL-zone #quality control #reference #safety glass #upgrades

At FLACHGLAS, a culture of operational excellence fuels continuous modernizations. “The latest Glaston ProL upgrade for our 50-year-old lamination line has helped us raise performance, save energy and automate production with the push of a button,” says Martin Geiss, Technical Manager at FLACHGLAS Wernberg.

Read moreFull Glass, Peru

#architectural #automation #flat glass tempering #glass tempering #glass tempering process #iControL #RC Series #reference #tempered glass

“We are very satisfied with the quality of our new RC Series tempering line and the glass it produces. The Vortex Pro convection control system is excellent. The furnace made by Glaston China is just as well manufactured as the previous furnace we bought from Glaston’s factory in Finland,” says Frank Calderón Gómez, Managing Director at Full Glass in Lima, Peru.

Read moreAGC Interpane, Germany

#architectural #automation #glass processing #IG unit #insulating glass #reference #technology

“I walk through our insulating glass production facility every day with pride,” says Daniel Bruckelt, Production Manager Insulating Glass of AGC Interpane in Plattling, Germany. “Not just because everything is so well organized and structured, but also because Glaston has given us a coherent concept for our unique insulating glass (IG) production. And this is what allows us to remain top-of-mind for challenging world-class projects.”

Read moreArticles

GPD 2023 Presentations – Sustainability and trends

The Glass Performance Days 2023 conference brought forward a compelling array of presentations focused on sustainability and emerging trends within the glass industry....

Read moreGPD 2023 Presentations – Glass processing technologies

The Glass Performance Days 2023 conference showcased a range of pioneering presentations on glass processing technologies, bringing together industry leaders and...

Read moreGPD 2023 Presentations – Architectural glass

The Glass Performance Days 2023 conference has once again brought together a wealth of knowledge and innovation from the leading minds in the glass industry. We...

Read more