Paragon Tempered Glass, U.S.A.

Reference - Americas

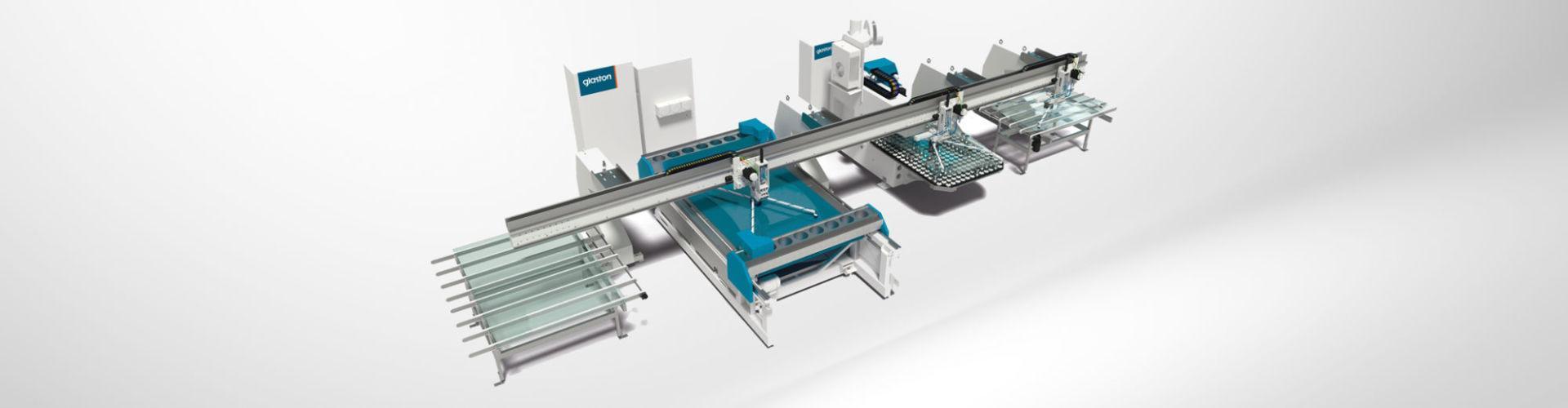

Glaston’s CHAMP 25 helps Paragon meet growing demands

“When we saw the CHAMP 25 a few years ago, we knew this was the future we should pursue for our next round of capital expenditures,” says Dan Wright, CEO of Paragon Tempered Glass.

Dan and his colleague Wes Brigner, Director of Manufacturing, already knew Bystronic glass and Glaston well from their vast experience in the glass industry. The two Paragon plants have 30-year-old Bystronic glass pre-processing equipment and Glaston tempering lines.

“We know that Glaston is very reliable, and the equipment does an awesome job,” says Wes. “We’ve always thought highly of the two equipment manufacturers that are now one Glaston.”

About two years ago, the men saw the CHAMP 25. They reached out to Glaston to learn more and decided it was the right path for their business.

“Not only would the line give us the speed and capacity we needed, we also knew our relationship with Glaston would be excellent and the quality would be of the highest caliber,” Dan says. And this all proved to be so – even down to the way the product was packaged and shipped.

“Of all the equipment we have purchased over the years, this machine came with the best packaging, instructions and top-of-the-line support,” Wes emphasizes. “When it came to support, the Glaston team had a response for us within minutes and a game plan to take care of any issue within an hour. This means the world to us!”

Paragon purchased their first CHAMP 25 in October 2019. Although COVID-19 slowed the process, the line was installed in September 2021. The new line incorporates four different processes – robotic loading, cutting, grinding and drilling with two sets of drills. Earlier, this would have taken four separate pieces of equipment. Now the line combines all processes into one and is tied into the company’s digital printer.

Automation opens door to greater capacity

CHAMP automates the processes, significantly improving yield and quality. At the same time, it helps Paragon focus on what they’re best at – fabricating a high volume of high value-added parts.

This is the direction their business is moving – providing parts with more holes and odder shapes – and serving new and different cab styles with a sharper look.

“Our operators are really excited about the CHAMP line, as they see this as the future. Especially at the Ohio plant, our people have adapted over the years to many changes and expect the best. They also know we share the business profits with our workforce. They understand that the better we do, the better they do, too,” Dan says.

Wes adds that the additional automation is helping them grow the business in a way they can excel without making the personnel work more hours.

“We’ve been short on team members and see automation as a way for us to work to live – and not live to work.”

Similar references

FLACHGLAS, Germany

#flat glass laminating #glass processing #glass quality #laminated glass #laminating #ProL #ProL-zone #quality control #reference #safety glass #upgrades

At FLACHGLAS, a culture of operational excellence fuels continuous modernizations. “The latest Glaston ProL upgrade for our 50-year-old lamination line has helped us raise performance, save energy and automate production with the push of a button,” says Martin Geiss, Technical Manager at FLACHGLAS Wernberg.

Read moreFull Glass, Peru

#architectural #automation #flat glass tempering #glass tempering #glass tempering process #iControL #RC Series #reference #tempered glass

“We are very satisfied with the quality of our new RC Series tempering line and the glass it produces. The Vortex Pro convection control system is excellent. The furnace made by Glaston China is just as well manufactured as the previous furnace we bought from Glaston’s factory in Finland,” says Frank Calderón Gómez, Managing Director at Full Glass in Lima, Peru.

Read moreAGC Interpane, Germany

#architectural #automation #glass processing #IG unit #insulating glass #reference #technology

“I walk through our insulating glass production facility every day with pride,” says Daniel Bruckelt, Production Manager Insulating Glass of AGC Interpane in Plattling, Germany. “Not just because everything is so well organized and structured, but also because Glaston has given us a coherent concept for our unique insulating glass (IG) production. And this is what allows us to remain top-of-mind for challenging world-class projects.”

Read moreArticles

GPD 2023 Presentations – Sustainability and trends

The Glass Performance Days 2023 conference brought forward a compelling array of presentations focused on sustainability and emerging trends within the glass industry....

Read moreGPD 2023 Presentations – Glass processing technologies

The Glass Performance Days 2023 conference showcased a range of pioneering presentations on glass processing technologies, bringing together industry leaders and...

Read moreGPD 2023 Presentations – Architectural glass

The Glass Performance Days 2023 conference has once again brought together a wealth of knowledge and innovation from the leading minds in the glass industry. We...

Read more