Semcoglas, Germany

Reference - Europe

Semcoglas uses insulating glass with thermoplastic spacers

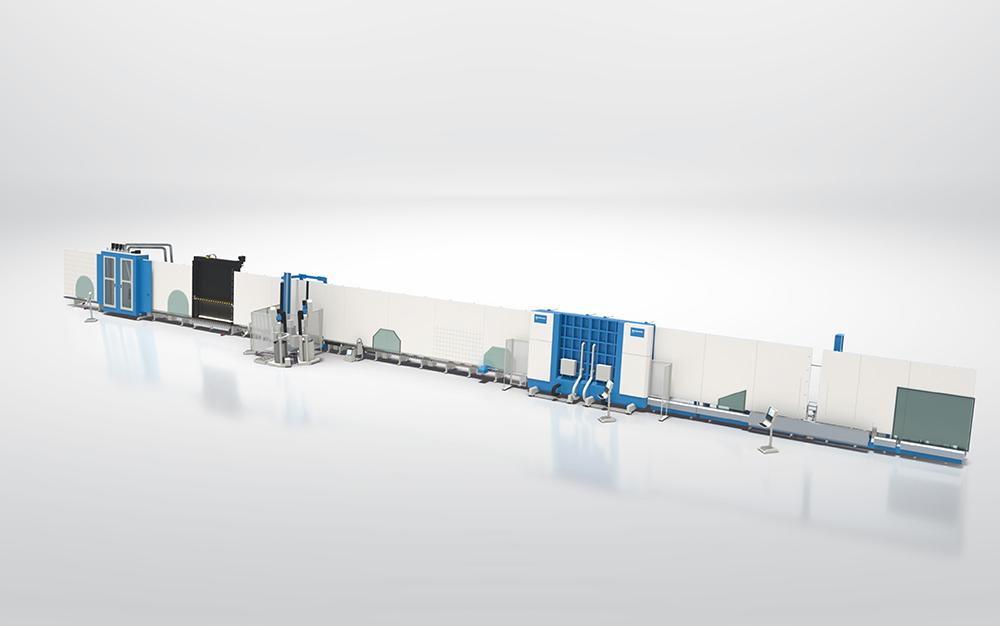

When Semcoglas added the German Aschaffenburg location to its Company Group in October 2003, the production facility only had an old glass cutting facility and a small insulating glass line at its disposal. Since the start of this year, Semcoglas has now been working with an ultra-modern Bystronic glass production line for the manufacture of insulating glass which uses glass supplied by a rapid HEGLA insulating glass feed system.

The new insulating glass line measures 64 metres in length and processes glass sizes ranging from 19 x 35 centimetres up to 2.70 x 5.00 metres. In doing so, the production is completely focused on the current and future requirements of the insulating glass customers.

The Company Group produces insulating glass in 15 of the 20 branches and has used Bystronic glass production lines for many years – mostly including the tps’applicator for the processing of thermoplastic spacers. “We made the conscious decision to invest in this future-oriented technology as it is one of the most advanced warm edge technologies on the market: The thermoplastic edge bond simultaneously replaces a conventional metallic spacer, the desiccant and the primary seal”, explains Michel Schüller, Technical Branch Manager in Aschaffenburg and son of the Managing Partner of the Semcoglas Group, Hermann Schüller. He goes on to explain: “As a result, the thermal bridges found at the edge of the insulating glass are considerably reduced compared to the conventional spacers, thus improving the internal temperature.”

“The use of thermoplastic spacers is of particular benefit when producing triple insulating glass units as both spacers are automatically applied without any offset whatsoever – even when dealing with shaped formats. As a result, we are able to achieve better quality even in terms of visual appearance. Semcoglas customers also appreciate this”

Similar references

FLACHGLAS, Germany

#flat glass laminating #glass processing #glass quality #laminated glass #laminating #ProL #ProL-zone #quality control #reference #safety glass #upgrades

At FLACHGLAS, a culture of operational excellence fuels continuous modernizations. “The latest Glaston ProL upgrade for our 50-year-old lamination line has helped us raise performance, save energy and automate production with the push of a button,” says Martin Geiss, Technical Manager at FLACHGLAS Wernberg.

Read moreFull Glass, Peru

#architectural #automation #flat glass tempering #glass tempering #glass tempering process #iControL #RC Series #reference #tempered glass

“We are very satisfied with the quality of our new RC Series tempering line and the glass it produces. The Vortex Pro convection control system is excellent. The furnace made by Glaston China is just as well manufactured as the previous furnace we bought from Glaston’s factory in Finland,” says Frank Calderón Gómez, Managing Director at Full Glass in Lima, Peru.

Read moreAGC Interpane, Germany

#architectural #automation #glass processing #IG unit #insulating glass #reference #technology

“I walk through our insulating glass production facility every day with pride,” says Daniel Bruckelt, Production Manager Insulating Glass of AGC Interpane in Plattling, Germany. “Not just because everything is so well organized and structured, but also because Glaston has given us a coherent concept for our unique insulating glass (IG) production. And this is what allows us to remain top-of-mind for challenging world-class projects.”

Read moreArticles

GPD 2023 Presentations – Sustainability and trends

The Glass Performance Days 2023 conference brought forward a compelling array of presentations focused on sustainability and emerging trends within the glass industry....

Read moreGPD 2023 Presentations – Glass processing technologies

The Glass Performance Days 2023 conference showcased a range of pioneering presentations on glass processing technologies, bringing together industry leaders and...

Read moreGPD 2023 Presentations – Architectural glass

The Glass Performance Days 2023 conference has once again brought together a wealth of knowledge and innovation from the leading minds in the glass industry. We...

Read more