At this year’s Vitrum trade fair taking place in Milan between October 23 and 26, Bystronic glass and Hegla will emphasise their preferred partner cooperation and will share stand space measuring 300 square metres. There, they will present their machines together: Bystronic glass handling equipment will equip a Hegla cutting table with glass. Of course, the other specialist fields of insulating glass production, laminated glass production and the pre-processing of automotive glass will also be showcased on the trade fair stand.

The Bystronic glass lines for insulating glass production and the systems for laminated glass production work together perfectly alongside the solutions for flat glass cutting from Hegla. As a result, the joint trade appearance offers a definitive advantage to customers and interested parties: They will be able to conduct talks comfortably with experts from both companies where necessary and obtain advice about the captivating technologies, all from one source.

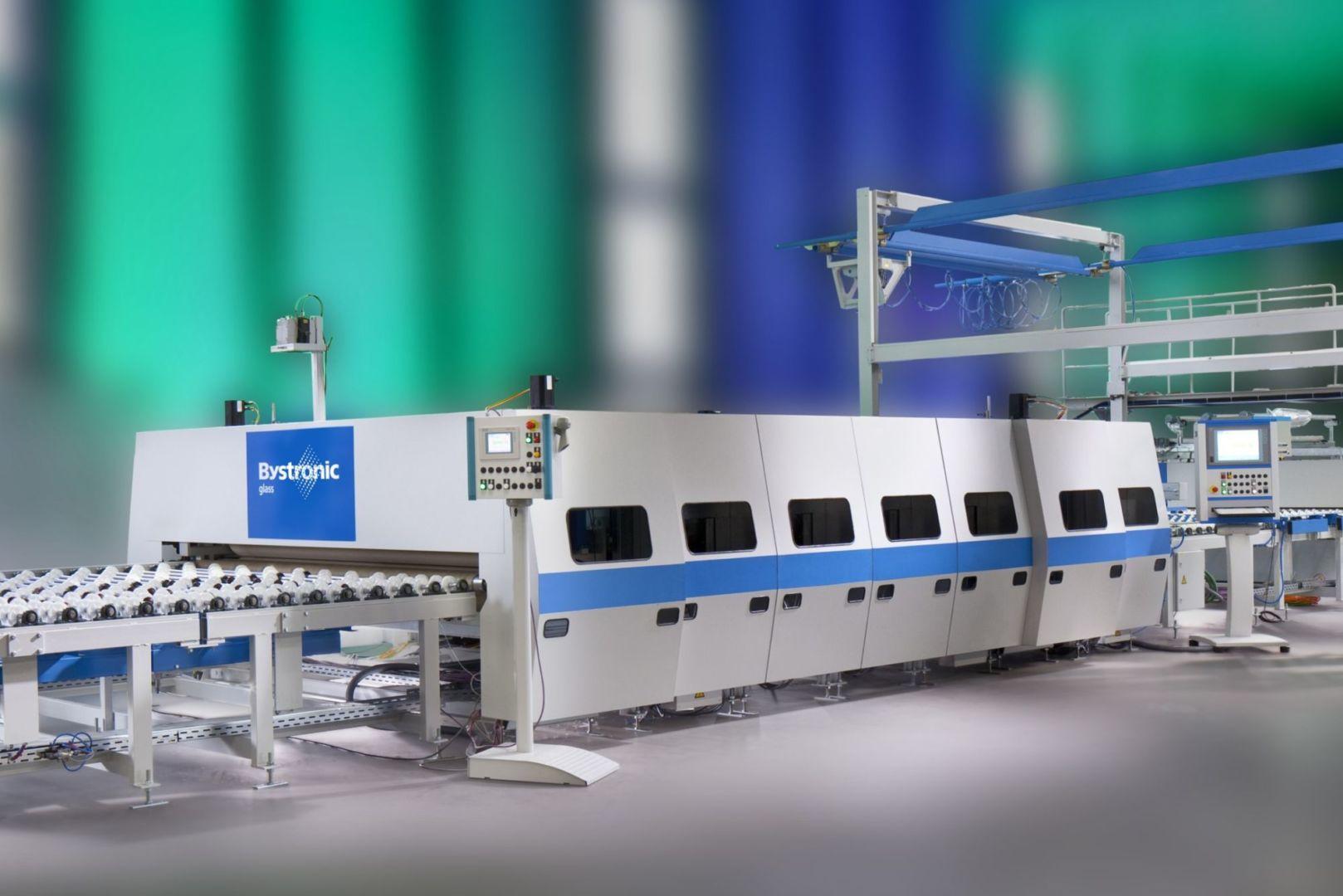

Insulating glass lines for the most diverse demands

Irrespective of whether a fully-automatic line for insulating glass production with warm-edge spacers or an entry-level solution: At Bystronic glass, every insulating glass manufacturer will find the line or machine that meets their requirements. The benchmark in this sector is the modern speed’line production line, which can be used to produce triple insulating glass units in the same time it takes other lines to produce double units. The line consists of two tps’applicator components arranged one after the other in order to apply the spacer, the new speed’assembler for the quick assembly and gas-filling of insulating glass units as well as the speed’sealer sealing robot. On the other side of the product range is the comfort’line, the ideal entry-level solution to industrial insulating glass production. Anybody on the lookout for an inexpensive opportunity to expand their production capacity is also well served with this model: The comfort’line offers high quality manufacturing of gas-filled insulating glass units at an excellent cost/performance ratio. In addition to the proven Bystronic glass quality, the insulating glass line convinces with its high productivity, low investment costs, a compact unit layout and individual expansion possibilities.

Proven, revolutionary technologies for laminated glass

In the laminated glass production sector, customers can obtain information about the eco’lamiline, the new production line, with which all versions of laminated glass can be produced in an energy-efficient manner – from simple constructions through to complex shaped formats with special films – all on a single system. The eco’convect, the pre-nip that is proven and continues to be revolutionary enables a homogeneous heat input that is obvious in the quality of the end product as it is crystal clear. And the “eco” part of the product name is not just down to chance: The radiant heater technology of the pre-nip controls the energy consumption to match the size of the laminate, meaning that a small laminate only requires half of the radiant heater output by comparison to a large laminate for example. The convection system also ensures a homogeneous heating in the pre-nip, even enabling the rational lamination of highly reflective, coated glasses. The omission of compressed air in the clean room of the eco’lamiline in favour of the servo technology that is seven times less expensive offers a further potential for saving that is beneficial both financially and in time management terms whilst also being beneficial to the environment.

Glas handling – take it easy

At the trade fair stand, customers will also be able to try a selection of rational handling equipment for all flat glass and plate processing sectors for themselves. This also includes the best seller, the Easy-Lift, which has been impressing customers from the glass processing industry with its rigid guidance and its own low dead weight since 1998. In recent years, the handling equipment has also gradually asserted itself with large window manufacturers as it is extremely flexible in terms of frame design and therefore fulfils their requirements. Track-mounted equipment as well as battery-powered suction frames complete the range.

Quick and precise pre-processing of automotive glass

A few years ago, Bystronic glass introduced a completely new machine generation for the pre-processing of automotive glass onto the market in the form of the champ’speed. More than 100 champ’speed units sold speak for themselves. In the meantime, the champ’speed 2in1 version, the first machine in the world that can break automotive glass with or without a template on a single machine has established itself. In addition to templates that support the glass during the cutting process and ensure a correspondingly high quality on the break edge, the champ’speed 2in1 is equipped with a freely manoeuvrable underlay that aligns itself to the break edges. Customers gain both functions in one cell and can flexibly switch between breaking with or without a template. This provides them with the opportunity to deploy the machine according to their requirements or orders as well as to optimise their production processes at the same time.

Service – wherever our customers need us

Right from the very first minute, Bystronic glass supports its customers during the planning of their unit. The customer service department is then on hand all over the world for the delivery of spare parts and on-site support. Maintenance contracts and individual training sessions round off the range of services on offer. Expert contact partners will be on hand at the Vitrum trade fair stand to provide information regarding the Bystronic glass service.