AGC Interpane, Germany

Reference - Europe

Tailoring a unique spacer application approach for world-class insulating glass

“I walk through our insulating glass production facility every day with pride,” says Daniel Bruckelt, Production Manager Insulating Glass of AGC Interpane in Plattling, Germany. “Not just because everything is so well organized and structured, but also because Glaston has given us a coherent concept for our unique insulating glass (IG) production. And this is what allows us to remain top-of-mind for challenging world-class projects.”

AGC Interpane’s Plattling plant, located at the gateway to the Bavarian Forest, produces high-quality semi-finished glass products and insulating glass. Since 2012, AGC Interpane has been coating glass up to 18 m x 3.21 m. This extra-long glass can be coated with a variety of solar control layers or iplus thermal insulation layers.

AGC Interpane’s Plattling site specializes in processing logistically complex, fixed-size insulating glass orders. The company’s magnetron sputtering system, a physical vapor deposition method that produces thin films and coating, differentiates the company from its competition. The system allows AGC Interpane to offer high-quality façade glass from a single source.

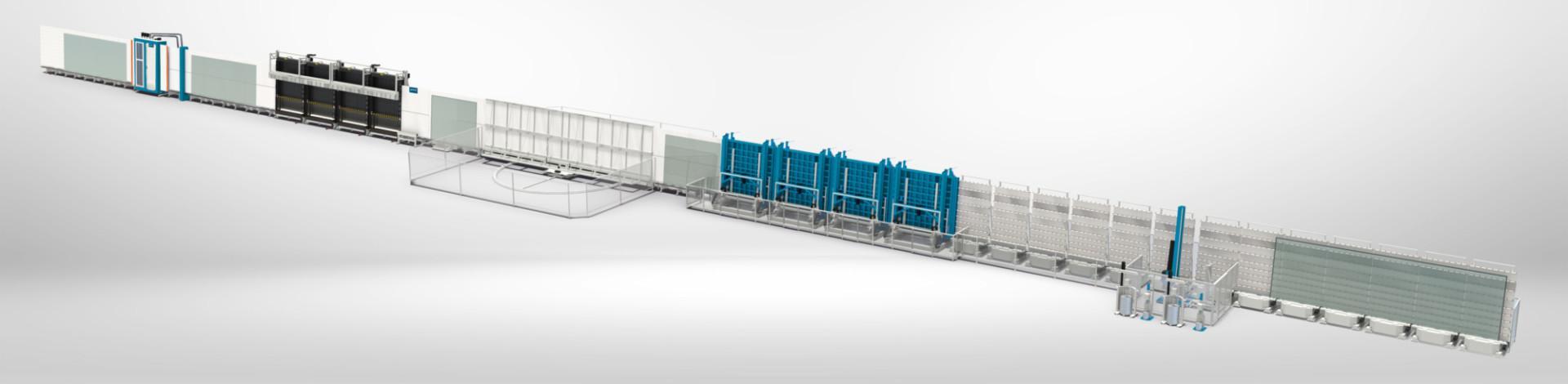

AGC Interpane has been a long-term customer of Glaston and the earlier brands that now belong to the Glaston family. The company currently has three Glaston insulating glass lines and one Glaston tempering line. The most recent addition, the Glaston JUMBO XXL FLEX line, was customized for AGC Interpane. The line was ordered in 2021 and commissioned in April 2022. It allows AGC Interpane to automatically produce jumbo formats up to 3.3 x 6 m.

Earlier, these could only be produced semi-automatically or with additional manual effort. The line includes standard components for edge deletion, glass cleaning and glass inspection as well as several specially engineered features.

“Glaston has given AGC Interpane a unique constellation in the spacer application sector. We are the only ones in the world to have this configuration. The UNIT’ASSEMBLER allows us to process special shapes and fill them automatically with gas. The SPEED’SEALER has eliminated any bottleneck at the end of the line. This means that it is now possible to automatically produce large insulating glass units weighing up to 600 kg / m.”

Similar references

Pilkington Automotive Finland, Finland

#automotive glass #automotiveindustry #CNC #CNC96 #lifecycleservices #mobility #reference #upgrades

“We decided to extend the lifetime of our Bystronic (now Glaston) automotive glass cutting equipment with a Glaston CNC96 upgrade kit and ensure that we can continue to get spare parts,” says Matti Säynäväjärvi, Technical Services Group Leader, Pilkington Automotive Finland Oy, Laitila plant.

Read moreViridian Glass, Australia

#architectural #automation #COMFORT #glass quality #IG unit #insulating glass #reference

As building regulations require more energy-efficient glass, Viridian Glass has stepped up its game. Purchasing Glaston’s COMFORT BOX IG manufacturing line enables its Woodville plant in Adelaide to meet burgeoning demands with visibly better quality and shorter lead times. “High quality insulated glass is the future in Australia,” says, National Operational Excellence Manager, Tarun Bhatia at Viridian Glass.

Read moreAGP, New Zealand

#architectural #automation #autopilot #digitalization #FC Series #flat glass tempering #reference

“We’re now running with the stability, reliability and consistency we aimed to achieve when we invested in Glaston’s Autopilot,” David Bunting, Managing Director of Architectural Glass Products (AGP), says.

Read moreArticles

Breakthroughs in automating glass processing

From traditional applications to cutting-edge capabilities, automation revolutionizes production, enhances quality and boosts efficiency. In this blog, we’ll discuss...

Read moreKey takeaways from glasstec 2024

Held in late October, glasstec 2024 buzzed with energy, robotic solutions and serious discussions. Based on what we saw and heard at the event, we can outline a...

Read moreKey applications of automation in glass processing

What glass processes gain the most from automation? In this blog, we’ll focus on some of the particularly promising application areas. As we discovered in the...

Read more