JUMBO & JUMBO XXL

The system solution for maximum requirements

Looking to aim big?

Here are three reasons why Glaston JUMBO and Glaston JUMBO XXL are your best choice

1.

Insulating glass units

up to 600 kg/m

2.

Maximum glass size

3.3 x 18 m

3.

“Green production” with optimum energy efficiency

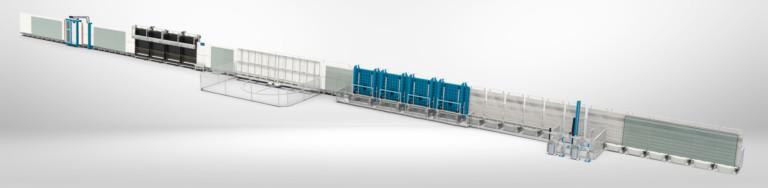

JUMBO & JUMBO XXL

Impressive insulating glass manufacturing in maximum size

Glaston JUMBO and Glaston JUMBO XXL are insulating glass lines specially designed for manufacturing large-sized insulating glass units and façade elements up to 18 m in length.

- Up to 600 kg per running meter with heavy unit capability

- Optimized insulating glass line energy efficiency

Edge deletion of jumbo units in rectangular and shaped formats

Automatic positioning and pressing of the upper frame edge

Automatic turning of coated glass plates up to 12 m in length

Automatic assembling, gas filling and pressing of up to four-sided stepped jumbo units

Continuous sealing of up to four-sided stepped jumbo units with up to 30 mm sealing depth

References

Pavle, Serbia

#architectural #automation #flat glass tempering #glass tempering #iControL #Jumbo Series #reference #safety glass #tempered glass

“With our Glaston Jumbo furnace and insulating line, we can now produce the biggest IG units in the Balkans, and our business is taking off internationally. The line helps us serve architects who want ever-larger, top-quality windows for offices, schools and even shopping malls with glass sizes up to 3.5 meters or more,” says Jelena Blagojevic, Marketing Manager of Pavle.

Read moreFull Glass, Peru

#architectural #automation #flat glass tempering #glass tempering #glass tempering process #iControL #RC Series #reference #tempered glass

“We are very satisfied with the quality of our new RC Series tempering line and the glass it produces. The Vortex Pro convection control system is excellent. The furnace made by Glaston China is just as well manufactured as the previous furnace we bought from Glaston’s factory in Finland,” says Frank Calderón Gómez, Managing Director at Full Glass in Lima, Peru.

Read moreAGC Interpane, Germany

#architectural #automation #glass processing #IG unit #insulating glass #reference #technology

“I walk through our insulating glass production facility every day with pride,” says Daniel Bruckelt, Production Manager Insulating Glass of AGC Interpane in Plattling, Germany. “Not just because everything is so well organized and structured, but also because Glaston has given us a coherent concept for our unique insulating glass (IG) production. And this is what allows us to remain top-of-mind for challenging world-class projects.”

Read moreArticles

The rise of thin triple insulating glass units: An industry game-changer

The push for better thermal performance in insulating glass units (IGUs) is greater than ever. For example, the 2024 Energy Star guidelines in the U.S. have set...

Read moreGPD 2023 Presentations – Sustainability and trends

The Glass Performance Days 2023 conference brought forward a compelling array of presentations focused on sustainability and emerging trends within the glass industry....

Read moreGPD 2023 Presentations – Architectural glass

The Glass Performance Days 2023 conference has once again brought together a wealth of knowledge and innovation from the leading minds in the glass industry. We...

Read more