BRIGHT 25

Maximum precision and productivity for large displays

Looking to perform precise cutting, breaking and grinding of large display glasses?

Here are three reasons why Glaston BRIGHT 25 is your best choice

1.

Two grinding wheels per grinding head

2.

Short cycle times

3.

High repetition accuracy and minimal grinding allowance

Glaston BRIGHT 25 is a line for the highly efficient and precise cutting, breaking and grinding of large display glasses. The design offers not only a process-optimized line layout, but also various expansion options using upgrade kits.

- Consistently rough and fine grinding for maximum edge strength and quality with two grinding wheels on one grinding head

- Short cycle times based on the simultaneous use of up to two tools on the same glass

- High repetition accuracy and minimal grinding allowance with a precise cutting and breaking tool

- High degree of automation with short changeover time

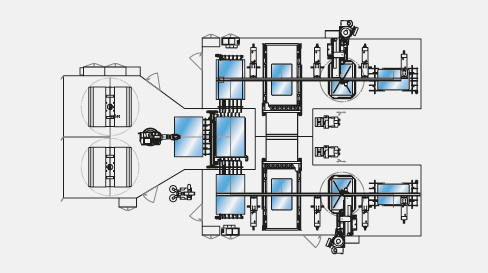

BRIGHT 25 VARIANT 1

The high-performance line for parallel production

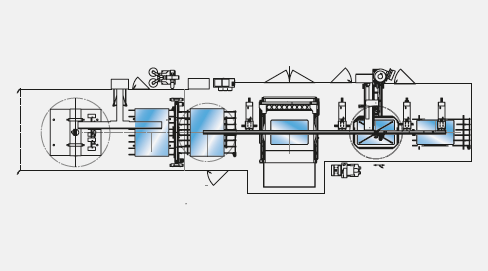

BRIGHT 25 VARIANT 2

The 2-in-1 system offers maximum flexibility in glass breaking, with or without a template

References

FLACHGLAS, Germany

#flat glass laminating #glass processing #glass quality #laminated glass #laminating #ProL #ProL-zone #quality control #reference #safety glass #upgrades

At FLACHGLAS, a culture of operational excellence fuels continuous modernizations. “The latest Glaston ProL upgrade for our 50-year-old lamination line has helped us raise performance, save energy and automate production with the push of a button,” says Martin Geiss, Technical Manager at FLACHGLAS Wernberg.

Read moreAGC Interpane, Germany

#architectural #automation #glass processing #IG unit #insulating glass #reference #technology

“I walk through our insulating glass production facility every day with pride,” says Daniel Bruckelt, Production Manager Insulating Glass of AGC Interpane in Plattling, Germany. “Not just because everything is so well organized and structured, but also because Glaston has given us a coherent concept for our unique insulating glass (IG) production. And this is what allows us to remain top-of-mind for challenging world-class projects.”

Read morePress Glass Inc., U.S.A.

#automation #flat glass laminating #glass processing #laminating #ProL #reference #safety glass #upgrades

Since establishing their presence in the US through an acquisition, Poland-based Press Glass has continued its brisk growth based on the same values that make it the #1 glass fabricator in Europe and the UK. The company’s latest US investment is a Glaston ProL convection control upgrade at its Ridgeway, Virginia, plant.

Read more