CHAMP EVO BL

Product-specific design for maximum precision and productivity of backlites

Looking for highly efficient processing of backlites or appliance glass?

Here are three reasons why Glaston CHAMP EVO BL is your best choice

1.

High repetition accuracy

2.

High degree of automation

3.

Short changeover time

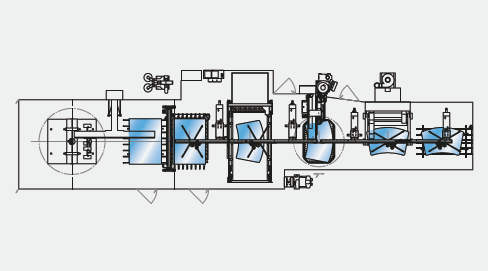

Glaston CHAMP EVO BL is a product-specific line for the highly efficient and precise cutting, breaking, grinding and drilling of backlites, appliance and solar glass. The standardized design not only offers a process-optimized line layout, but also various expansion options using upgrade kits.

- Highly efficient and precise cutting, breaking, grinding and drilling

- Process-optimized line layout and space saving footprint

- Individual configurations possible, also only grinding and drilling of cut glass

- Ability to use several grinding wheels for rough and fine grinding without manual intervention

- Various expansion options using upgrade kits

- High degree of automation with the shortest changeover time

CHAMP EVO BL VARIANT

Fully integrated design for simultaneous drilling of two holes

References

Pilkington Automotive Finland, Finland

#automotive glass #automotiveindustry #CNC #CNC96 #lifecycleservices #mobility #reference #upgrades

“We decided to extend the lifetime of our Bystronic (now Glaston) automotive glass cutting equipment with a Glaston CNC96 upgrade kit and ensure that we can continue to get spare parts,” says Matti Säynäväjärvi, Technical Services Group Leader, Pilkington Automotive Finland Oy, Laitila plant.

Read moreVitropor, Portugal

#architectural #automation #flat glass laminating #flat glass tempering #glass processing #glass tempering #iControL #laminating #ProL #reference #RHC #safety glass #tempered glass #upgrades

“When we buy a new TV or piece of furniture for our home, it gives us good vibes – a nice feeling. In a similar way, we chose to upgrade our tempering furnace to make things easier and better for our team, so their work would be more enjoyable,” says Pedro Aguilar, Managing Director of Vitropor.

Read moreFLACHGLAS, Germany

#flat glass laminating #glass processing #glass quality #laminated glass #laminating #ProL #ProL-zone #quality control #reference #safety glass #upgrades

At FLACHGLAS, a culture of operational excellence fuels continuous modernizations. “The latest Glaston ProL upgrade for our 50-year-old lamination line has helped us raise performance, save energy and automate production with the push of a button,” says Martin Geiss, Technical Manager at FLACHGLAS Wernberg.

Read more