CHAMP EVO BL

Product-specific design for maximum precision and productivity of backlites

Looking for highly efficient processing of backlites or appliance glass?

Here are three reasons why Glaston CHAMP EVO BL is your best choice

1.

High repetition accuracy

2.

High degree of automation

3.

Short changeover time

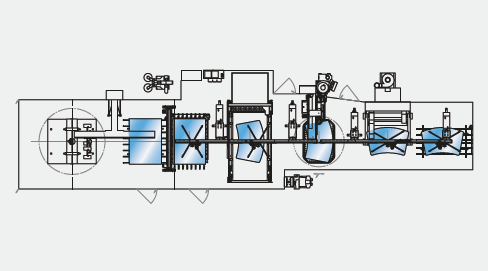

Glaston CHAMP EVO BL is a product-specific line for the highly efficient and precise cutting, breaking, grinding and drilling of backlites, appliance and solar glass. The standardized design not only offers a process-optimized line layout, but also various expansion options using upgrade kits.

- Highly efficient and precise cutting, breaking, grinding and drilling

- Process-optimized line layout and space saving footprint

- Individual configurations possible, also only grinding and drilling of cut glass

- Ability to use several grinding wheels for rough and fine grinding without manual intervention

- Various expansion options using upgrade kits

- High degree of automation with the shortest changeover time

CHAMP EVO BL VARIANT

Fully integrated design for simultaneous drilling of two holes

References

FLACHGLAS, Germany

#flat glass laminating #glass processing #glass quality #laminated glass #laminating #ProL #ProL-zone #quality control #reference #safety glass #upgrades

At FLACHGLAS, a culture of operational excellence fuels continuous modernizations. “The latest Glaston ProL upgrade for our 50-year-old lamination line has helped us raise performance, save energy and automate production with the push of a button,” says Martin Geiss, Technical Manager at FLACHGLAS Wernberg.

Read moreAGC Interpane, Germany

#architectural #automation #glass processing #IG unit #insulating glass #reference #technology

“I walk through our insulating glass production facility every day with pride,” says Daniel Bruckelt, Production Manager Insulating Glass of AGC Interpane in Plattling, Germany. “Not just because everything is so well organized and structured, but also because Glaston has given us a coherent concept for our unique insulating glass (IG) production. And this is what allows us to remain top-of-mind for challenging world-class projects.”

Read moreLippert Components, USA

#automation #automotive #automotive glass #bending #CHAMP #CHF #glass bending #glass tempering #Matrix #reference #safety glass

Tim Widner at Lippert Components in the US is sharing his and his team's experiences working with the Glaston glass processing machinery. "The new equipment has been a great addition to us. We are able to one-piece flow our raw material through our line, hands-free. No humans come in contact with the glass until it is fully tempered and at the end of the process."

Read more