COMPACT & COMFORT

Start-up solutions in automated insulating glass production

Looking to start automated insulating glass production?

Here are three reasons why Glaston COMPACT and Glaston COMFORT are your best choice

1.

Up to 800 gas-filled insulating glass units per shift

2.

Low investment costs

3.

Compact line layout

The Glaston COMPACT and Glaston COMFORT provide high quality I.G. unit manufacturing with an excellent cost/performance ratio – optional with gas filling by Glaston COMFORT.

In addition to the proven quality and reliability, these I.G. lines offer real added value.

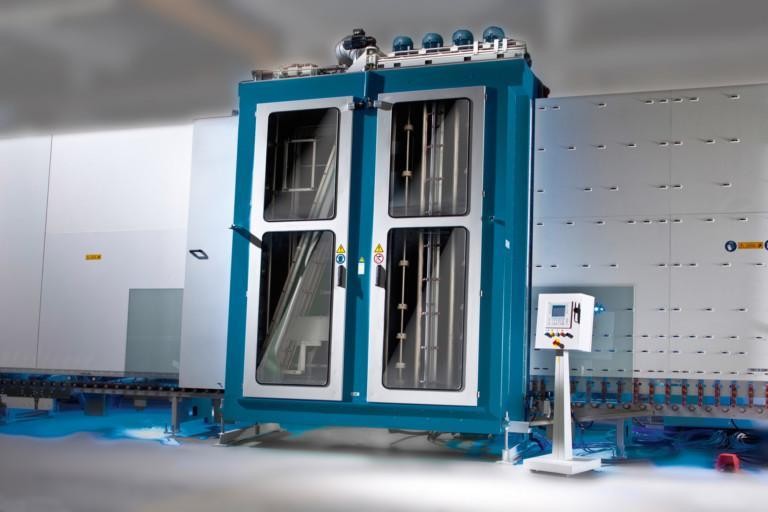

COMPACT

Your entry into the world of insulating glass manufacturing.

Double-sided spacer frame coating with thermoplastic sealants

Coated glass plate edge deletion

COMFORT

Your entry into the world of insulating glass manufacturing with automated gas filling.

Continuous washing and drying of diverse glass plates

Visual glass inspection and manual positioning of spacer frames

Automatic assembling, gas filling and pressing of I.G. units

Continuous sealing of I.G. units of different formats and dimensions

References

FLACHGLAS, Germany

#flat glass laminating #glass processing #glass quality #laminated glass #laminating #ProL #ProL-zone #quality control #reference #safety glass #upgrades

At FLACHGLAS, a culture of operational excellence fuels continuous modernizations. “The latest Glaston ProL upgrade for our 50-year-old lamination line has helped us raise performance, save energy and automate production with the push of a button,” says Martin Geiss, Technical Manager at FLACHGLAS Wernberg.

Read moreFull Glass, Peru

#architectural #automation #flat glass tempering #glass tempering #glass tempering process #iControL #RC Series #reference #tempered glass

“We are very satisfied with the quality of our new RC Series tempering line and the glass it produces. The Vortex Pro convection control system is excellent. The furnace made by Glaston China is just as well manufactured as the previous furnace we bought from Glaston’s factory in Finland,” says Frank Calderón Gómez, Managing Director at Full Glass in Lima, Peru.

Read moreAGC Interpane, Germany

#architectural #automation #glass processing #IG unit #insulating glass #reference #technology

“I walk through our insulating glass production facility every day with pride,” says Daniel Bruckelt, Production Manager Insulating Glass of AGC Interpane in Plattling, Germany. “Not just because everything is so well organized and structured, but also because Glaston has given us a coherent concept for our unique insulating glass (IG) production. And this is what allows us to remain top-of-mind for challenging world-class projects.”

Read moreArticles

GPD 2023 Presentations – Sustainability and trends

The Glass Performance Days 2023 conference brought forward a compelling array of presentations focused on sustainability and emerging trends within the glass industry....

Read moreGPD 2023 Presentations – Glass processing technologies

The Glass Performance Days 2023 conference showcased a range of pioneering presentations on glass processing technologies, bringing together industry leaders and...

Read moreGPD 2023 Presentations – Architectural glass

The Glass Performance Days 2023 conference has once again brought together a wealth of knowledge and innovation from the leading minds in the glass industry. We...

Read more