Craneways and slewing cranes

Individually integrated craneways and slewing cranes

Looking for tailored handling machines that work with your production?

Here are three reasons why craneways and slewing cranes are your best choice

1.

Customer-specific X–Y craneway design

2.

Optionally available with assembly

3.

Slewing crane as a low-price solution to work in a circular area

CRANEWAY

- Smooth running with a large operating area

- Different suspension possibilities available using existing structures or separate supports

- Available with a travel drive for heavy weights

- Jib constructions or steel substructure where required

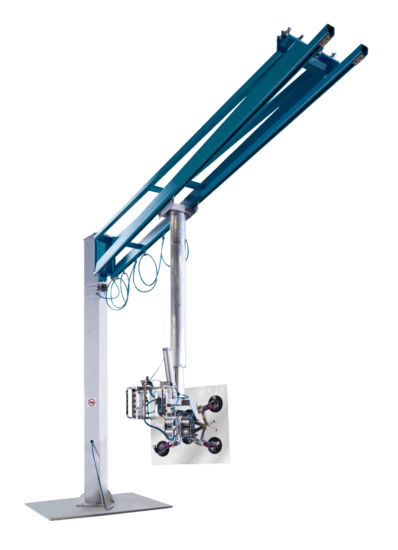

SLEWING CRANE

- Serves as a wall slewing crane or pillar slewing crane

- Working length of up to 6 meters

- Also available with a slewing drive when dealing with heavy weights

- Height of the jib edge designed according to customer requirements

References

AURYS, France

#appliances #automation #autopilot #energy efficiency #flat glass tempering #glass tempering #interior #RC Series #reference #safety glass

“We had an excellent opportunity to replace our two older tempering furnaces with one new Glaston RC Series line to reduce energy consumption, avoid problems with outdated spare parts and beef up our production with more automation,” says Samir Bou Obeid, Chairman of AURYS.

Read moreEuroglas, Belgium

#flat glass tempering #glass tempering #iControL #RHC #safety glass #tempered glass #upgrades

Euroglas chose Glaston’s Roller Heat Control (RHC) upgrade to improve its tempering line performance as part of a series of investments to grow with its customers. “We aim to offer the width and depth of glass products they need to be their best partner,” says Frederik De Knijf, CEO of Euroglas in Belgium.

Read morePilkington Automotive Finland, Finland

#automotive glass #automotiveindustry #CNC #CNC96 #lifecycleservices #mobility #reference #upgrades

“We decided to extend the lifetime of our Bystronic (now Glaston) automotive glass cutting equipment with a Glaston CNC96 upgrade kit and ensure that we can continue to get spare parts,” says Matti Säynäväjärvi, Technical Services Group Leader, Pilkington Automotive Finland Oy, Laitila plant.

Read moreArticles

Does turning a tempering furnace off really save energy?

Some manufacturers suggest you can save energy by heating the furnace from room temperature in just one hour at the start of each shift. Does this approach actually...

Read moreTempering energy-consumption claims – don’t fall for them

Modern tempering technologies bring glass processors significant energy efficiencies. However, some tempering line manufacturers make energy-saving claims that sound...

Read moreBreakthroughs in automating glass processing

From traditional applications to cutting-edge capabilities, automation revolutionizes production, enhances quality and boosts efficiency. In this blog, we’ll discuss...

Read more