Edge processing

Quick and economical high-quality glass arrissing

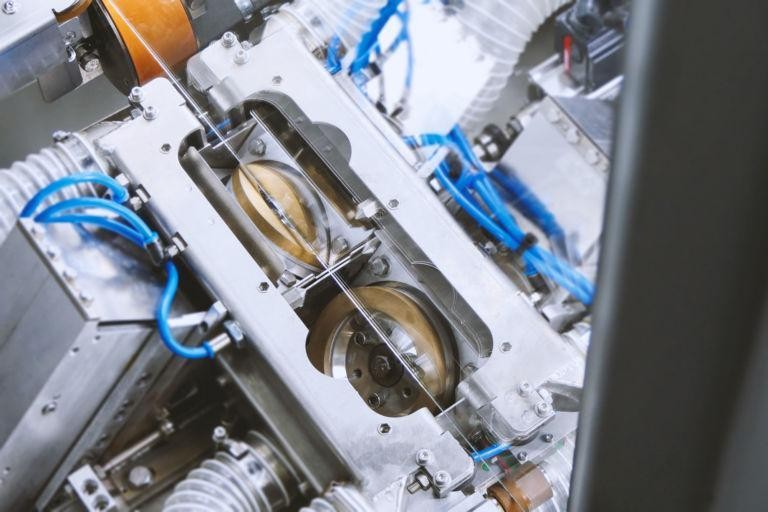

The 3in1 glass arrissing solution with cup wheel technology

1.

Versatile and flexible applications

- Automatic arrssing of rectangular and shaped glasses

- Straight edges and radii – both possible

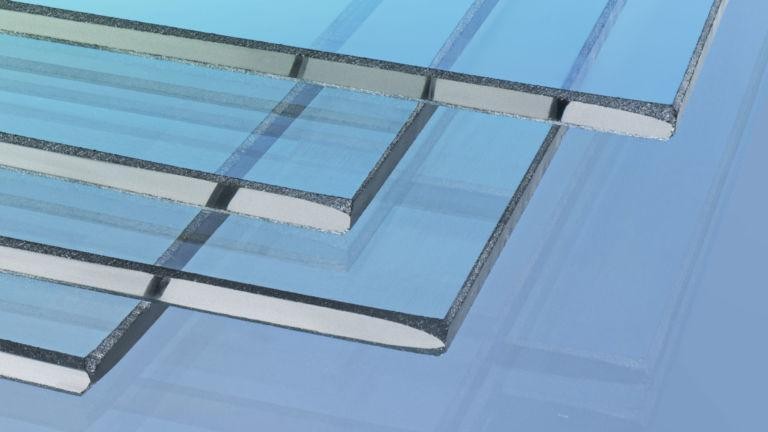

- Float glass, tempered glass and laminated glass

2.

Homogeneous and uniform arrissing quality

- Edge arrissing

- Flat edge arrissing

- Corner dubbing

3.

Economical and accurate production

- Highest process speed up to 60 m/min (edge and flat edge)

- Low cycle times & operating costs

- No tool change with the cup wheel technology

MULTI'ARRISSER

Automatic vertical arrissing machine

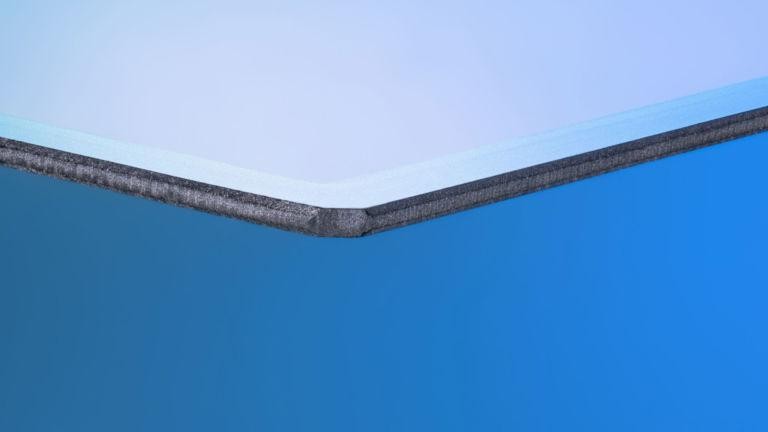

Homogeneous and uniform arrissing quality even at the beginning and the end

- Best arrissing quality through the use of cup wheels.

- Compared to profiled wheels, the contact surface to the glass with cup wheels is much higher.

- Material removal is distributed over several diamonds and thus becomes more even.

Highest arrissing speed

- The cup wheels allow a maximum arrissing speed of 60m/min (also for flat edge).

- With these speed the MULTI’ARRISSER is the fastest single-head-machine worldwide.

No tool change necessary

- Always the same cup wheels are used for different glass plate thicknesses and different functions.

One cup wheel for multiple functions

- Different glass thickness from 3 mm to 25 mm

- Different functions such as edge, flat side, corner dubbing are realized with the same cup wheel

- No loss of production time in mixed operation

- Only one wear part

- Best price/performance ratio for the tool due to simplest geometry

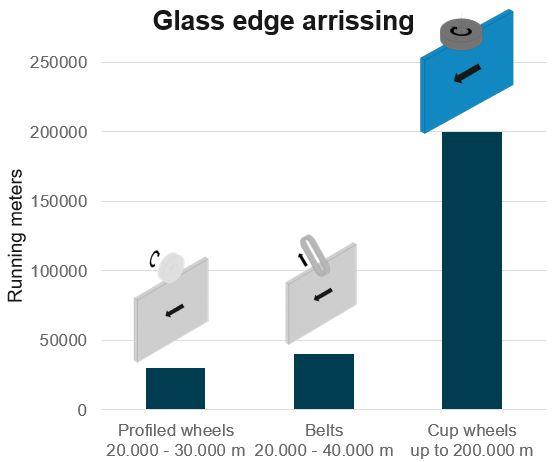

Long lifetime of arrissing tool

- 5 to 10 times higher lifetime for glass edge arrissing than all other arrissing systems

- Higher productivity due to higher uptime

- Less service interventions due to less shutdown time

- Possible cost reduction within a shortest period of time due to longer lifespan of the tools

References

Full Glass, Peru

#architectural #automation #flat glass tempering #glass tempering #glass tempering process #iControL #RC Series #reference #tempered glass

“We are very satisfied with the quality of our new RC Series tempering line and the glass it produces. The Vortex Pro convection control system is excellent. The furnace made by Glaston China is just as well manufactured as the previous furnace we bought from Glaston’s factory in Finland,” says Frank Calderón Gómez, Managing Director at Full Glass in Lima, Peru.

Read moreAGC Interpane, Germany

#architectural #automation #glass processing #IG unit #insulating glass #reference #technology

“I walk through our insulating glass production facility every day with pride,” says Daniel Bruckelt, Production Manager Insulating Glass of AGC Interpane in Plattling, Germany. “Not just because everything is so well organized and structured, but also because Glaston has given us a coherent concept for our unique insulating glass (IG) production. And this is what allows us to remain top-of-mind for challenging world-class projects.”

Read moreEmirates Glass, UAE

#architectural #automation #flat glass tempering #glass tempering #iLooK #Jumbo Series #reference #safety glass #tempered glass

Emirates Glass LLC, one of the leading organizations in the glass industry and a long-time advocate of Glaston technology, continues its journey of innovation and quality enhancement with the installation of the Glaston Jumbo Series flat glass tempering line featuring Vortex Pro convection technology. This investment marks Emirates Glass’s commitment to delivering top-notch architectural glass solutions to the region and far beyond.

Read moreArticles

GPD 2023 Presentations – Sustainability and trends

The Glass Performance Days 2023 conference brought forward a compelling array of presentations focused on sustainability and emerging trends within the glass industry....

Read moreGPD 2023 Presentations – Glass processing technologies

The Glass Performance Days 2023 conference showcased a range of pioneering presentations on glass processing technologies, bringing together industry leaders and...

Read moreGPD 2023 Presentations – Architectural glass

The Glass Performance Days 2023 conference has once again brought together a wealth of knowledge and innovation from the leading minds in the glass industry. We...

Read more