TPS® – Thermo Plastic Spacer

The Original. Proven since 1994.

Sustainable, efficient and durable.

1.

MODERN & FLEXIBLE

- TPS® allows applying the thermoplastic spacer material directly onto the glass plate

- Most modern and flexible solution

- Simplifies organization within the factory

- Even mixed production can be flexibly manufactured on a single line in an endless mode – without any loss of time.

2.

PROVEN SINCE 1994

- Glaston launched the technology into the market in 1994

- Over 170 TPS® systems in use globally

- Several million TPS® IG units installed

3.

HIGH AUTOMATIZATION

- Only one single machine instead of separate IG production processes

- No more bending, sawing, connecting, filling and butyl coating necessary

- Spacer widths can be changed automatically without manual intervention

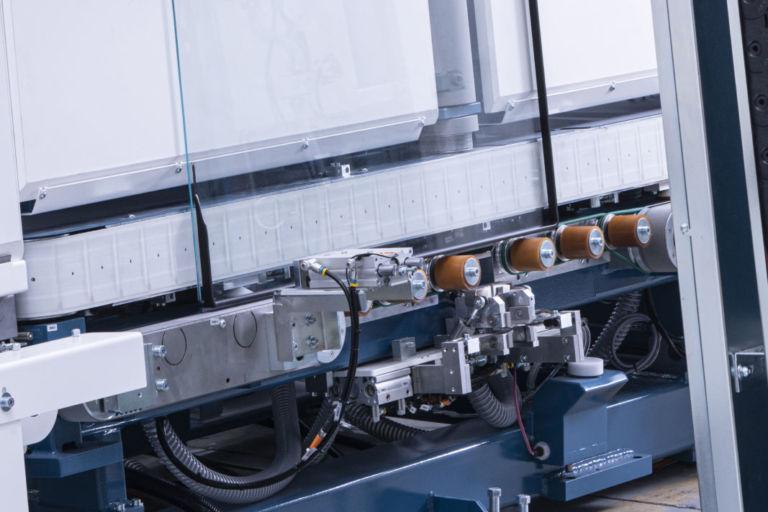

New drum pump system

- Glaston is the inventor of the dual-drum pump system for an entirely interruption-free production process. This guarantees a continuous material flow even if drum changes take place during production

- NEW: Glaston-patented, specially designed follower plate

- Higher heating capacity and optimized material flow. This leads to up to 35% improved material output and productivity

- No need to reduce the speed for larger spacer widths or larger glass plates

- New drum pump system is available as an upgrade for all existing Glaston TPS®IG manufacturing lines with SIMOTION control

New drum trolley system

- TPS® features a new drum trolley system

- The trolley system enables a simple drum change in less than three minutes. The same process takes around 10 minutes for alternative solutions

- Easy to use, the new drum trolley system requires only four actions from the operator: unlock, lift, replace, lock

- No need for heavy lifting, eliminating risks to operator health and safety

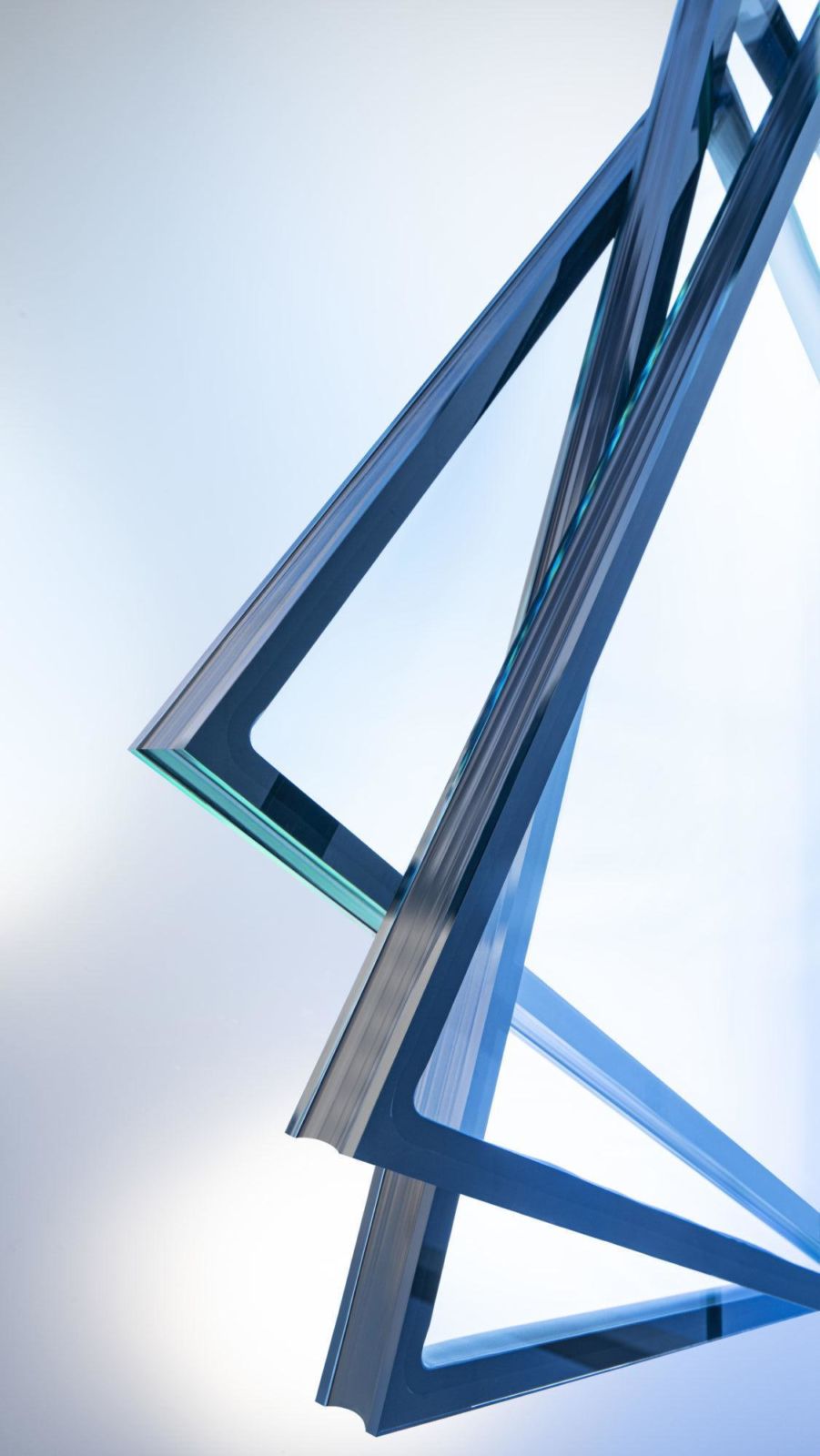

Bevel joint

- Glaston can now address individual customer needs and position the bevel joint in every corner, which makes it almost invisible

- The bevel joint positioning on the glass side is also possible

- It is suitable for all glass formats and spacer widths between 4 and 20 mm

- Unlike other solutions on the market, Glaston’s bevel joint doesn’t require any thermal-mechanical reworking or finishing processes

- Irrespective of radii, small or large airspaces between the glass units, Glaston’s bevel joint ensures the highest gas tightness

- When installed in a window frame, it makes the final aesthetic appearance admirable

And more...

References

Glas Dreisbusch, Germany

#architectural #IG unit #insulating glass #TPS #VARIO

“The idea of a special U-shaped design to fit our confined space was created over lunch by my son Maximillian Dreisbusch and two Glaston service engineers. I think this says everything about our close and collaborative partnership with Glaston,” says Thomas Dreisbusch, Managing Director of Glas Dreisbusch.

Read moreNortheast Building Products, U.S.A.

#architectural #glass processing #IG unit #insulating glass #reference #TPS #VARIO

With over 650 employees, Northeast Building Products, based in Philadelphia PA, USA, manufactures high quality, energy efficient windows, doors and ancillary products for the residential window and door market. Alan Levin, President of NBP, has partnered with Bystronic glass since 2009 when they invested in the cutting edge Sashlite™ technology, SashLine, to support the company’s diversification and growth strategy.

Read moreMetro Performance Glass, New Zealand

#architectural #glass processing #IG unit #insulating glass #JUMBO #reference #TPS

Bystronic glass once again achieved great success after the commissioning and installation of a new B’JUMBO I.G. line in Auckland, New Zealand. The progressive project is part of an expansion phase at one of Australasia’s leading glass processors – Metro Performance Glass.

Read moreArticles

GPD 2023 Presentations – Sustainability and trends

The Glass Performance Days 2023 conference brought forward a compelling array of presentations focused on sustainability and emerging trends within the glass industry....

Read moreGPD 2023 Presentations – Glass processing technologies

The Glass Performance Days 2023 conference showcased a range of pioneering presentations on glass processing technologies, bringing together industry leaders and...

Read moreGPD 2023 Presentations – Architectural glass

The Glass Performance Days 2023 conference has once again brought together a wealth of knowledge and innovation from the leading minds in the glass industry. We...

Read more