Metro Performance Glass, New Zealand

Reference - Asia

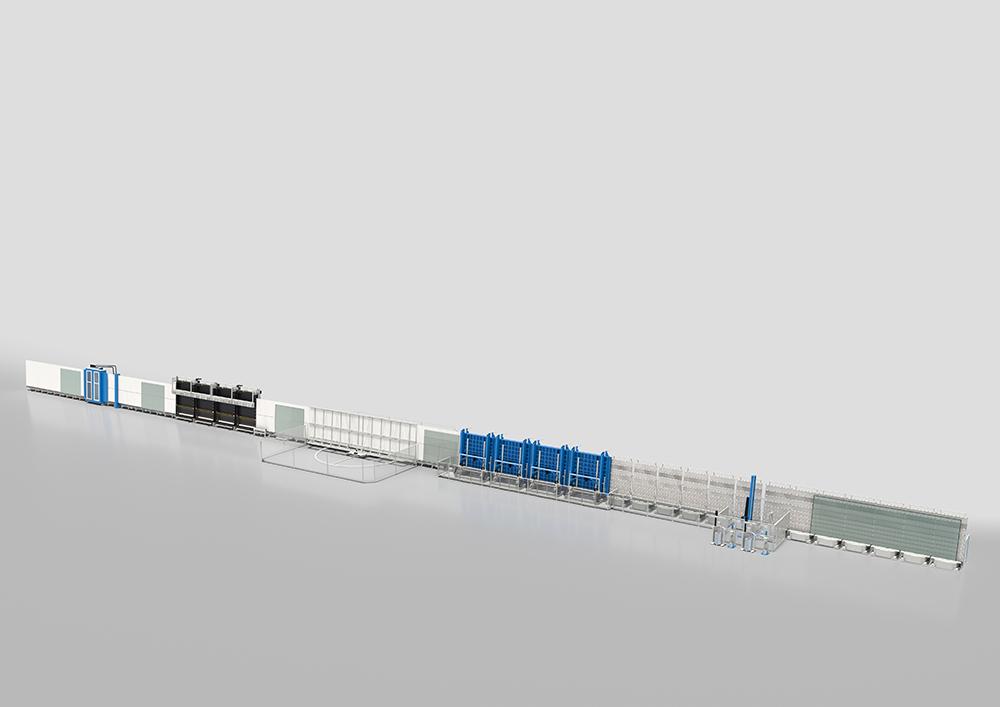

Metro Performance Glass New Zealand to set new industry standards with Bystronic glass B’JUMBO installation

Bystronic glass once again achieved great success after the commissioning and installation of a new B’JUMBO I.G. line in Auckland, New Zealand. The progressive project is part of an expansion phase at one of Australasia’s leading glass processors – Metro Performance Glass.

With a broad product range that caters for both domestic and commercial markets Metro Performance Glass has established a reputation for excellence which their customers rely upon. The B’JUMBO IG production line from Bystronic glass was the preferred choice for this installation, with its technically advanced capabilities that provide greater accuracy and faster output to cope with market demands as they increase.

As product design in the glass market diversifies, the need to invest in greater automation that can easily handle an expanding product range, that includes double glazed units, laminated glass products as well as toughened and heat soaked glass, became essential for the Highbrook based manufacturers.

Accommodating glass dimensions from min. 190 x 350 mm, max. 3210 x 6000 mm, the B’JUMBO system can produce insulating glass units or commercial units from 12 – 80 mm in thickness. Using the Bystronic glass shape catalogue, customers can diversify their portfolio, enabling products to be manufactured in a variety of dimensions and styles. The system opens up new opportunities for Bystronic glass customers, particularly in the commercial sector, and makes an excellent solution in relation to the market’s desire for more dynamic design.

“During a tough economic climate that is dominated by continual change, the quality of build, reliability and support services are essential for us from a supplier. The Bystronic glass team have been great to work with as they developed a rapport and worked with us throughout the whole process, from advising and commissioning the line to training our operators on the equipment post-installation. They gave us confidence in the company as a whole, performing to the highest of standards during our transition phase, which at times had challenging moments.”

Similar references

FLACHGLAS, Germany

#flat glass laminating #glass processing #glass quality #laminated glass #laminating #ProL #ProL-zone #quality control #reference #safety glass #upgrades

At FLACHGLAS, a culture of operational excellence fuels continuous modernizations. “The latest Glaston ProL upgrade for our 50-year-old lamination line has helped us raise performance, save energy and automate production with the push of a button,” says Martin Geiss, Technical Manager at FLACHGLAS Wernberg.

Read moreFull Glass, Peru

#architectural #automation #flat glass tempering #glass tempering #glass tempering process #iControL #RC Series #reference #tempered glass

“We are very satisfied with the quality of our new RC Series tempering line and the glass it produces. The Vortex Pro convection control system is excellent. The furnace made by Glaston China is just as well manufactured as the previous furnace we bought from Glaston’s factory in Finland,” says Frank Calderón Gómez, Managing Director at Full Glass in Lima, Peru.

Read moreAGC Interpane, Germany

#architectural #automation #glass processing #IG unit #insulating glass #reference #technology

“I walk through our insulating glass production facility every day with pride,” says Daniel Bruckelt, Production Manager Insulating Glass of AGC Interpane in Plattling, Germany. “Not just because everything is so well organized and structured, but also because Glaston has given us a coherent concept for our unique insulating glass (IG) production. And this is what allows us to remain top-of-mind for challenging world-class projects.”

Read moreArticles

GPD 2023 Presentations – Sustainability and trends

The Glass Performance Days 2023 conference brought forward a compelling array of presentations focused on sustainability and emerging trends within the glass industry....

Read moreGPD 2023 Presentations – Glass processing technologies

The Glass Performance Days 2023 conference showcased a range of pioneering presentations on glass processing technologies, bringing together industry leaders and...

Read moreGPD 2023 Presentations – Architectural glass

The Glass Performance Days 2023 conference has once again brought together a wealth of knowledge and innovation from the leading minds in the glass industry. We...

Read more