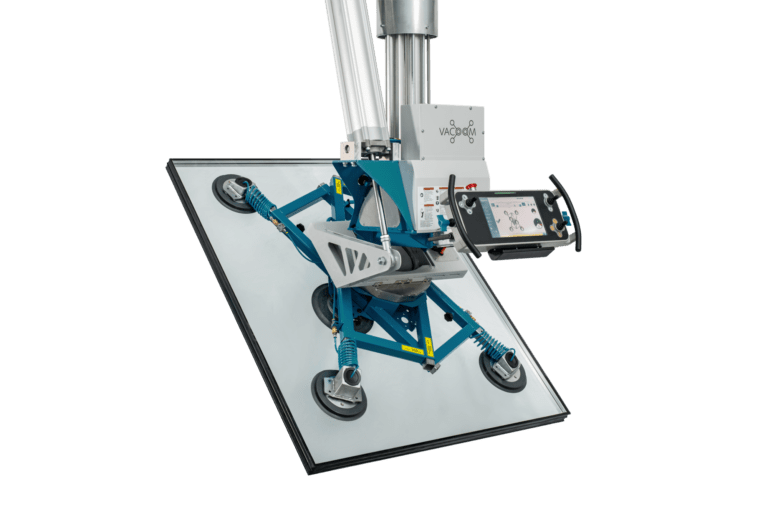

VACOOM’LIFTER

The new generation of handling equipment

Looking for a new-generation handling machine?

Here are three reasons why Glaston VACOOM’LIFTER is your best choice

1.

Increased safety standards

2.

Proven, rigid guidance

3.

Sensors for predictive maintenance of components

Tangible benefits

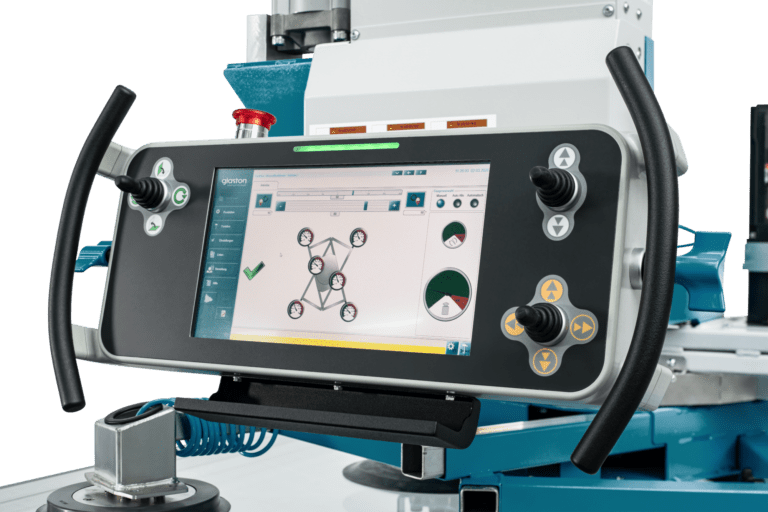

The newly developed Glaston VACOOM’LIFTER handling machine represents a successful combination of traditional equipment manufacturing processes and digital transformation. Let’s call it Glaston 4.0 in practical use.

- Accurate positioning with stepless, adjustable lifting speed

- Vacuum generation with intelligent ejector technology

- System status in real time

- Malfunction avoidance

- Integrated energy-saving function

- Integrated load cell protection against overload

- Maximum possible weight only when using all suction cups

- Automatic load reduction with deactivated suction cups

- Safe parking of transported goods with automatic recognition of successful load docking

- Various evaluation options for process and suction cycles over a longer period of time

- Platform concept for different device versions

- Rigid guidance

- Hooks into crane hooks or chain hoists

References

Pavle, Serbia

#architectural #automation #flat glass tempering #glass tempering #iControL #Jumbo Series #reference #safety glass #tempered glass

“With our Glaston Jumbo furnace and insulating line, we can now produce the biggest IG units in the Balkans, and our business is taking off internationally. The line helps us serve architects who want ever-larger, top-quality windows for offices, schools and even shopping malls with glass sizes up to 3.5 meters or more,” says Jelena Blagojevic, Marketing Manager of Pavle.

Read moreFLACHGLAS, Germany

#flat glass laminating #glass processing #glass quality #laminated glass #laminating #ProL #ProL-zone #quality control #reference #safety glass #upgrades

At FLACHGLAS, a culture of operational excellence fuels continuous modernizations. “The latest Glaston ProL upgrade for our 50-year-old lamination line has helped us raise performance, save energy and automate production with the push of a button,” says Martin Geiss, Technical Manager at FLACHGLAS Wernberg.

Read moreFull Glass, Peru

#architectural #automation #flat glass tempering #glass tempering #glass tempering process #iControL #RC Series #reference #tempered glass

“We are very satisfied with the quality of our new RC Series tempering line and the glass it produces. The Vortex Pro convection control system is excellent. The furnace made by Glaston China is just as well manufactured as the previous furnace we bought from Glaston’s factory in Finland,” says Frank Calderón Gómez, Managing Director at Full Glass in Lima, Peru.

Read more