Long Nhien, Vietnam

Reference - Asia

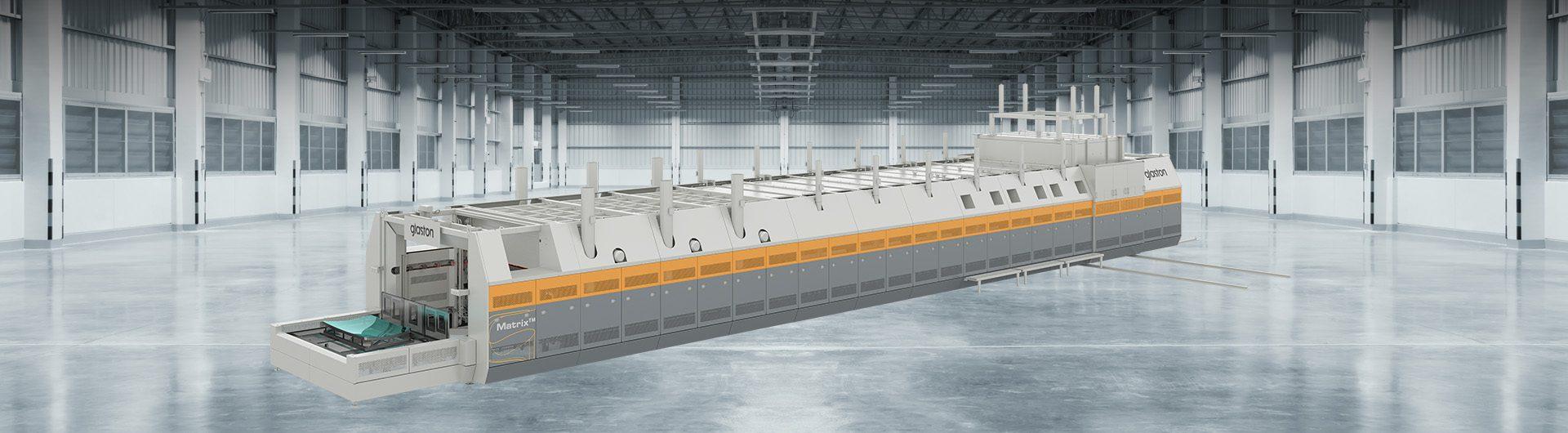

Long Nhien builds capacity to serve Vietnamese automotive market

“The market in Vietnam for cars is very large with lots of room for growth. People are becoming wealthier, and sitting in a car is more comfortable than being on a scooter, which may be prohibited in the next few years,” says Nguyen Phuong Tran, Production Manager, and son of Long Nhien Automotive Glass’s owners, about his home market. “The Glaston Matrix windshield bending furnace is a stepping stone for us to tap into this rapidly expanding business of hundreds of thousands new cars per year.”

Business for the family did not always have such a positive view to the future. Tran’s father always had a passion for windshields, but that market was highly competitive. He recognized, however, that no one was tempering glass in Vietnam at the time. So, in 2001, he established his company by bringing back some old tempering machinery from Australia that he fixed up. “It wasn’t until 2014 that my parents bought their first laminating line from China when the market started to grow and demand expanded. It was a bending furnace, primarily used for bus windshields.”

“My whole life, I had no knowledge about glass,” Tran explains. “When I searched on YouTube, Glaston popped up. Others already knew Glaston was the best in the world. After watching the video on YouTube countless times, I felt it was the most beautiful furnace I’d ever seen. It looked so cool! Since we were aiming to move into passenger cars, Glaston Matrix was the only choice.”

About a year ago, the company contacted Glaston and signed the agreement for a Matrix windshield bending furnace. The new Matrix was installed and commissioned in only 2.5 weeks in mid- May 2019. “I had never installed a machine before,” Tran says. “But my parents and everyone in the factory were really impressed. Of the 10 machines we have at our factory, this was by far the quickest one ever.”

“Yes, the Matrix YouTube video showed the windshields coming out of production quickly – but this was much faster than I expected in reality,”

Similar references

FLACHGLAS, Germany

#flat glass laminating #glass processing #glass quality #laminated glass #laminating #ProL #ProL-zone #quality control #reference #safety glass #upgrades

At FLACHGLAS, a culture of operational excellence fuels continuous modernizations. “The latest Glaston ProL upgrade for our 50-year-old lamination line has helped us raise performance, save energy and automate production with the push of a button,” says Martin Geiss, Technical Manager at FLACHGLAS Wernberg.

Read moreFull Glass, Peru

#architectural #automation #flat glass tempering #glass tempering #glass tempering process #iControL #RC Series #reference #tempered glass

“We are very satisfied with the quality of our new RC Series tempering line and the glass it produces. The Vortex Pro convection control system is excellent. The furnace made by Glaston China is just as well manufactured as the previous furnace we bought from Glaston’s factory in Finland,” says Frank Calderón Gómez, Managing Director at Full Glass in Lima, Peru.

Read moreAGC Interpane, Germany

#architectural #automation #glass processing #IG unit #insulating glass #reference #technology

“I walk through our insulating glass production facility every day with pride,” says Daniel Bruckelt, Production Manager Insulating Glass of AGC Interpane in Plattling, Germany. “Not just because everything is so well organized and structured, but also because Glaston has given us a coherent concept for our unique insulating glass (IG) production. And this is what allows us to remain top-of-mind for challenging world-class projects.”

Read moreArticles

GPD 2023 Presentations – Glass processing technologies

The Glass Performance Days 2023 conference showcased a range of pioneering presentations on glass processing technologies, bringing together industry leaders and...

Read moreSolving windscreen and sunroof production issues with convection preheating

The complexity of automotive windshields and sunroofs has significantly increased with evolving modern car designs. Achieving uniform heating for such complex glass...

Read moreEnergy efficiency best practices in automotive glass production

In this blog, we share some practical tips for optimizing energy consumption in automotive glass production. From preprocessing to final inspection, there is huge...

Read more