Glaston Insight Automotive PLUS

Performance increasing digital service upgrade package

For operator and production support

1.

Upgrade your Glaston CHAMP or BRIGHT machine

2.

Increase your daily performance and productivity

3.

Benefit from a steadily growing selection of digital services

Your benefits from Glaston Insight Automotive PLUS

With Glaston Insight Automotive PLUS you will easily improve your performance and productivity. Save precious time and money and take advantage of the full potential of your diamond tools. This digital service is the perfect completion to our exclusive Glaston grinding tools, designed to match 100% customer requirements.

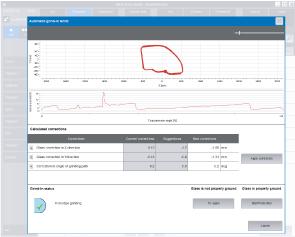

Auto centering

Automatic self-adjustment of the grinding machine after job change.

Lower your tool cost based on an automatic optimized set up of the grinding parameters what leads to an extended grinding wheel life time. Increase your productivity significantly by saving up to 70% of the time normally needed for a job change.

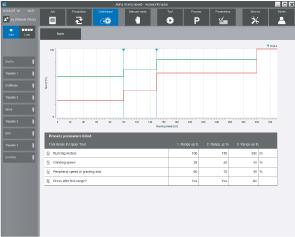

Tool break-in

Fully customizable break-in process for new grinding tools.

Extend the lifetime of your expensive grinding tools and make sure that even the first pane after a tool change is on the highest quality level by setting a defined running-in procedure easily.

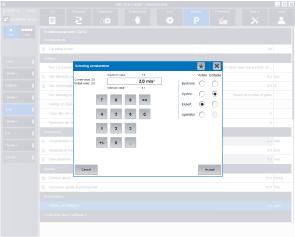

User setting

Individually assignable user rights for each parameter.

Protect your investment and ensure the highest quality level for your customers. Make sure that only authorized and trained personnel have access to critical machine parameters.

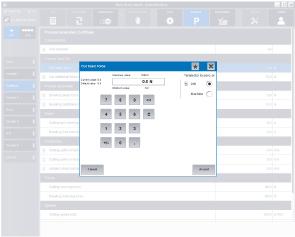

Parameter setting

Individually designable parameter storage for customer-specific production optimization.

Master all job dependent parameters and increase your productivity by setting up your customized production parameter database.

Advanced control system ACS3

All Glaston Insight Automotive Digital Services are designed to operate on our Microsoft Windows 10 based advanced control system ACS3, which is available for all machines from 2010 on.

- Intuitive and operator friendly HMI: Usable even without keyboard and mouse, supports multi touch gestures

- Favorite parameters: Create your own parameter hit list as a short cut and adapt them immediately without scrolling through many different menus

- Simplified parameter structure of only 3 categories: tool, process, machine

- Multiple languages: Switch instantly between 11 pre-installed languages

- Job Change Assistant: Menu-guided and self-explaining job change procedures support your operators to save valuable production

time - Pre-installed digital services such as our “Job Report” or “Logfile Analyzer”

References

Pilkington Automotive Finland, Finland

#automotive glass #automotiveindustry #CNC #CNC96 #lifecycleservices #mobility #reference #upgrades

“We decided to extend the lifetime of our Bystronic (now Glaston) automotive glass cutting equipment with a Glaston CNC96 upgrade kit and ensure that we can continue to get spare parts,” says Matti Säynäväjärvi, Technical Services Group Leader, Pilkington Automotive Finland Oy, Laitila plant.

Read moreVitropor, Portugal

#architectural #automation #flat glass laminating #flat glass tempering #glass processing #glass tempering #iControL #laminating #ProL #reference #RHC #safety glass #tempered glass #upgrades

“When we buy a new TV or piece of furniture for our home, it gives us good vibes – a nice feeling. In a similar way, we chose to upgrade our tempering furnace to make things easier and better for our team, so their work would be more enjoyable,” says Pedro Aguilar, Managing Director of Vitropor.

Read moreFLACHGLAS, Germany

#flat glass laminating #glass processing #glass quality #laminated glass #laminating #ProL #ProL-zone #quality control #reference #safety glass #upgrades

At FLACHGLAS, a culture of operational excellence fuels continuous modernizations. “The latest Glaston ProL upgrade for our 50-year-old lamination line has helped us raise performance, save energy and automate production with the push of a button,” says Martin Geiss, Technical Manager at FLACHGLAS Wernberg.

Read moreArticles

Breakthroughs in automating glass processing

From traditional applications to cutting-edge capabilities, automation revolutionizes production, enhances quality and boosts efficiency. In this blog, we’ll discuss...

Read moreKey takeaways from glasstec 2024

Held in late October, glasstec 2024 buzzed with energy, robotic solutions and serious discussions. Based on what we saw and heard at the event, we can outline a...

Read moreKey applications of automation in glass processing

What glass processes gain the most from automation? In this blog, we’ll focus on some of the particularly promising application areas. As we discovered in the...

Read more