IG Manufacturing Equipment

Reduce your risk and upgrade now!

Service Upgrade Kits for older IG Manufacturing Equipment

1.

Electronic components are discontinued?

This happens faster than you think and 1:1 replacement is almost never possible. In the event of damage, you first have to make complex hardware and software adjustments in order to be able to produce again. Long downtimes are then unavoidable.

2.

Earn money reliably even with our older machines

Avoid financial losses due to incalculable situations. Our specialists from the Glaston Service Upgrade Team analyse your system. You will receive a qualified risk analysis from us, which will serve as a basis for decisions on how to proceed.

3.

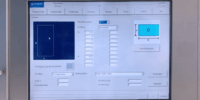

Various upgrade kits available

We have developed and prepared various upgrade kits for you, which we offer at a calculable fixed price plus installation costs. Leave nothing to chance – be proactive and upgrade your IG manufacturing equipment now!

All at a glance.

The procedure step by step:

- Hardware components that are no longer available must be replaced

- Within a few weeks, we deliver prepared upgrade kits, install them in your systems and make any necessary adjustments

- Plannable conversion duration, e.g. by use of maintenance slots

- Afterwards, the new components are again available from stock

- Training of your staff through instruction in the new components

- Updating of the machine documentation and modification of the spare parts lists

References

Pilkington Automotive Finland, Finland

#automotive glass #automotiveindustry #CNC #CNC96 #lifecycleservices #mobility #reference #upgrades

“We decided to extend the lifetime of our Bystronic (now Glaston) automotive glass cutting equipment with a Glaston CNC96 upgrade kit and ensure that we can continue to get spare parts,” says Matti Säynäväjärvi, Technical Services Group Leader, Pilkington Automotive Finland Oy, Laitila plant.

Read moreViridian Glass, Australia

#architectural #automation #COMFORT #glass quality #IG unit #insulating glass #reference

As building regulations require more energy-efficient glass, Viridian Glass has stepped up its game. Purchasing Glaston’s COMFORT BOX IG manufacturing line enables its Woodville plant in Adelaide to meet burgeoning demands with visibly better quality and shorter lead times. “High quality insulated glass is the future in Australia,” says, National Operational Excellence Manager, Tarun Bhatia at Viridian Glass.

Read moreVitropor, Portugal

#architectural #automation #flat glass laminating #flat glass tempering #glass processing #glass tempering #iControL #laminating #ProL #reference #RHC #safety glass #tempered glass #upgrades

“When we buy a new TV or piece of furniture for our home, it gives us good vibes – a nice feeling. In a similar way, we chose to upgrade our tempering furnace to make things easier and better for our team, so their work would be more enjoyable,” says Pedro Aguilar, Managing Director of Vitropor.

Read moreArticles

Tempering energy-consumption claims – don’t fall for them

Modern tempering technologies bring glass processors significant energy efficiencies. However, some tempering line manufacturers make energy-saving claims that sound...

Read moreBreakthroughs in automating glass processing

From traditional applications to cutting-edge capabilities, automation revolutionizes production, enhances quality and boosts efficiency. In this blog, we’ll discuss...

Read moreKey takeaways from glasstec 2024

Held in late October, glasstec 2024 buzzed with energy, robotic solutions and serious discussions. Based on what we saw and heard at the event, we can outline a...

Read more