EASY’LIFTERS

Ergonomic, universal handling equipment

Looking to handle flat glass efficiently?

Here are three reasons why Glaston EASY'LIFTERS are your best choice

1.

Careful load handling

2.

Minimized operator effort

3.

Quick, efficient and safe glass lifting

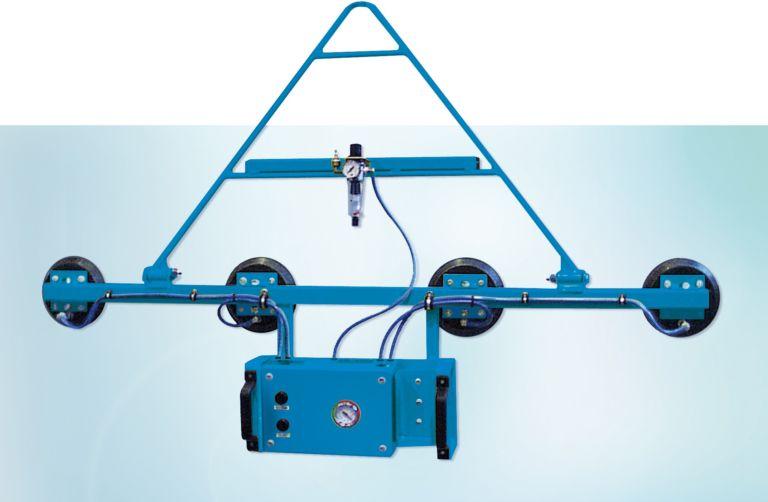

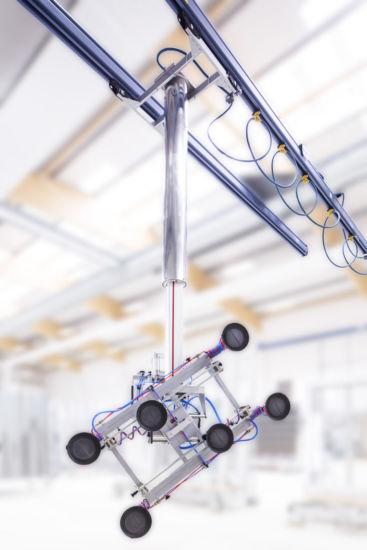

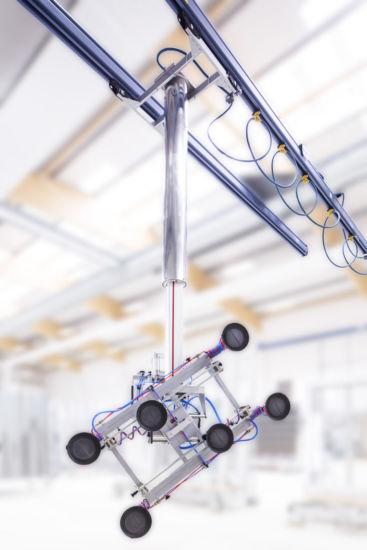

One-column lifters

Glass handling made easy

One-column lifters simplify glass handling thanks to their low dead weight and rigid guidance. The vacuum lifters are used in an X–Y craneway or slewing crane. All functions of the lifting equipment with a column are achieved pneumatically. The vacuum lifting technology works using Venturi nozzles.

- Enables unrivaled simple lifting, tilting or inclining, and turning of glass plates

- Suction using Venturi nozzles or a vacuum pump powered by compressed air

- Available in versions with a lifting capacity of 150, 250, 350 or 500 kg

- For simple vertical transportation

- Enables lifting, tilting, inclining and turning (also endless)

- Available in versions with a lifting capacity of 150 or 250 kg

- Safe, simple and functional design with rigid handling equipment guidance

- Accurate positioning via stepless, adjustable lifting speed

- Vacuum creation through powerful Venturi nozzles, which include a latching system for each suction pad

- Functionally designed operating elements

- Adjustable suction pads

- Low dead weight

- Low maintenance requirements

- Easy-to-operate lifter for the positioning and removal of vertical glass units

- Particularly suitable for the lifting and turning of smaller glass plates up

to 2 m2 - Lifting capacity of up to 250 kg

- Special equipment for the turning of glass units by up to 180°

- Can be hung into a lightweight craneway

- Available in versions with a lifting capacity of 150, 250 or 300 kg

Two-column lifters

All-inclusive device for handling heavy glass units

The two-column lifter simplifies the handling of big and heavy glass units thanks to rigid guidance. The two-column variant lifts, tilts, inclines and turns glass plates weighing up to 1,000 kg. The vacuum lifting device is utilized in an X–Y craneway in lightweight construction. The vacuum is generated on the suction lift either using an electrical vacuum pump or Venturi nozzles.

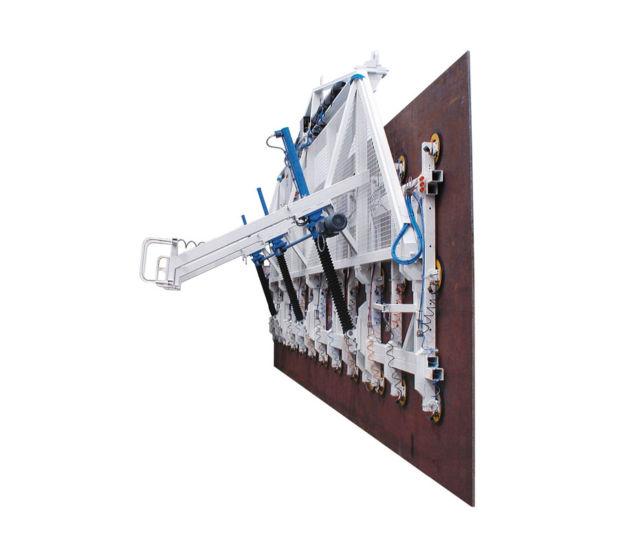

Manipulators

Vacuum hoists that can be used flexibly

The manipulators are particularly suitable for use in chain hoists, cable hoists or hall cranes. Vacuum is generated either using an electrical vacuum pump or Venturi nozzles.

- For use on vertical glass processing machines, such as grinding machines

- Continuously turns glass plates electronically

- Addition to the one-column lifter for oversized glass units

- Available in versions with a lifting capacity of up to 2,000 kg

- Suction unit for the vertical transport, carrying or turning of glass plates by up to 90°

- Often used in insulating glass production and window construction

- Available in various types with a lifting capacity of up to 350 kg

- Manual or pneumatic turning function

- Special equipment to be hung in hoisting gear

- Tilts and turns glass plates where horizontal to vertical positioning movements have to be made

- Available in versions with a lifting capacity of up to 5,000 kg

Accumulator lifters

Practicable solutions for vertical glass handling

These glass suction devices are ideal for the vertical handling of glass, for example, in a storage or cutting area.

- Standard device for vertical glass transport of heavy and large glass units of up to even jumbo sizes

- Vertical glass handling and removal from an insulating glass line

- Available in versions with a lifting capacity of up to 2,500 kg

- Also available as a very light suction lifter to transport units in a lifting device

- Autonomous, battery-powered glass suction device for mobile use

- Ideal for use on construction sites

- Flexible use in diverse lifting devices

- Variable combination of suction pads and connectors

- Available in versions with a lifting capacity of 220 or 600 kg

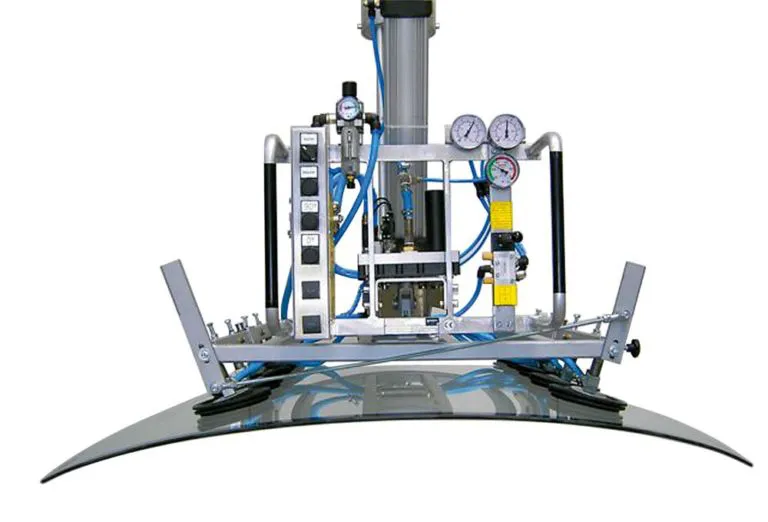

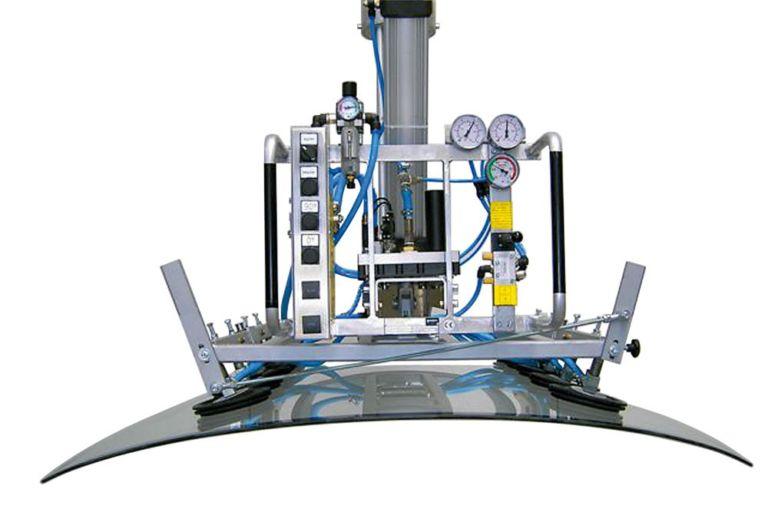

Special applications

Integration of special glass handling into the daily routine

Even the handling of extremely large glass plates or curved plates is child’s play with our handling equipment for special applications. The loading and unloading of systems with closed tops as well as screen printing units can be done without any problems whatsoever.

- Handling equipment for convex and concave curved glass units

- Stepless, pneumatic turning and tilting up to 90°

- Lifting capacity: 250 kg

- Vacuum lifter for the unloading of screen printing systems

- 360° horizontal rotation

- Removable suction pads and rubberized fork arms

- Lifting capacity: 350 kg

- Handling equipment to load CNC centers with closed tops

- Lifting and tilting, 360° horizontal rotation

- Lifting capacity: 150 kg

- Vacuum lifter to handle extremely large glass units and weights

- For use with hall cranes

- Suction frame tilts to a maximum 90° and can be extended from 10 to 13 meters

- Lifting capacity: 5,000 kg

EASY'LIFTER WINDOW

Vacuum hoist for excellent efficiency in the window manufacturing sector

- Safe, simple and functional design with rigid handling equipment guidance

- Accurate positioning via stepless, adjustable lifting speed

- Vacuum creation through powerful Venturi nozzles which include a latching system for each suction pad

- Functionally designed operating elements

- Adjustable suction pads

- Low dead weight

- Low maintenance

References

Euroglas, Belgium

#flat glass tempering #glass tempering #iControL #RHC #safety glass #tempered glass #upgrades

Euroglas chose Glaston’s Roller Heat Control (RHC) upgrade to improve its tempering line performance as part of a series of investments to grow with its customers. “We aim to offer the width and depth of glass products they need to be their best partner,” says Frederik De Knijf, CEO of Euroglas in Belgium.

Read morePilkington Automotive Finland, Finland

#automotive glass #automotiveindustry #CNC #CNC96 #lifecycleservices #mobility #reference #upgrades

“We decided to extend the lifetime of our Bystronic (now Glaston) automotive glass cutting equipment with a Glaston CNC96 upgrade kit and ensure that we can continue to get spare parts,” says Matti Säynäväjärvi, Technical Services Group Leader, Pilkington Automotive Finland Oy, Laitila plant.

Read moreViridian Glass, Australia

#architectural #automation #COMFORT #glass quality #IG unit #insulating glass #reference

As building regulations require more energy-efficient glass, Viridian Glass has stepped up its game. Purchasing Glaston’s COMFORT BOX IG manufacturing line enables its Woodville plant in Adelaide to meet burgeoning demands with visibly better quality and shorter lead times. “High quality insulated glass is the future in Australia,” says, National Operational Excellence Manager, Tarun Bhatia at Viridian Glass.

Read moreArticles

Does turning a tempering furnace off really save energy?

Some manufacturers suggest you can save energy by heating the furnace from room temperature in just one hour at the start of each shift. Does this approach actually...

Read moreTempering energy-consumption claims – don’t fall for them

Modern tempering technologies bring glass processors significant energy efficiencies. However, some tempering line manufacturers make energy-saving claims that sound...

Read moreBreakthroughs in automating glass processing

From traditional applications to cutting-edge capabilities, automation revolutionizes production, enhances quality and boosts efficiency. In this blog, we’ll discuss...

Read more