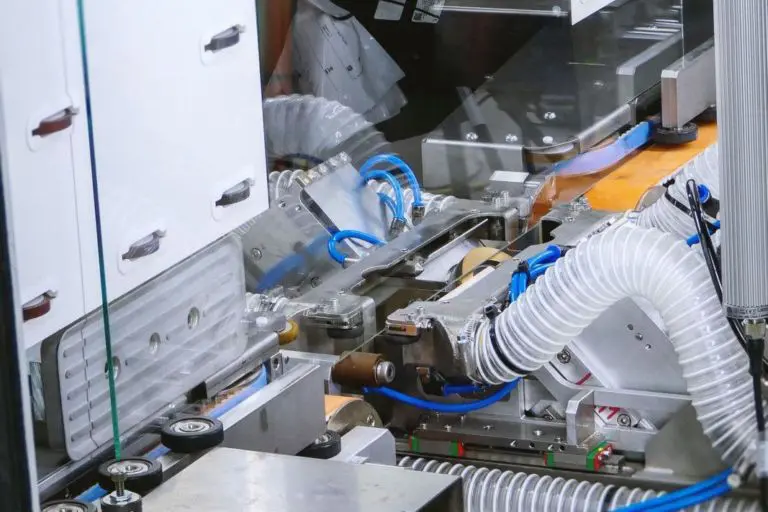

Edge processing

Quick and economical high-quality glass arrissing

The 3in1 glass arrissing solution with cup wheel technology

1.

Versatile and flexible applications

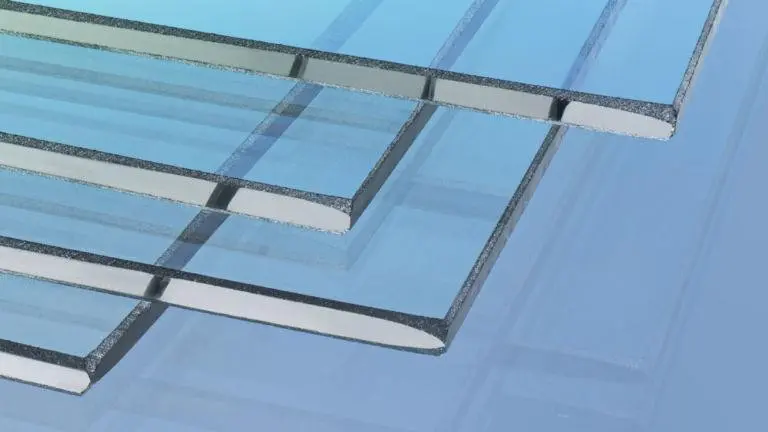

- Automatic arrssing of rectangular and shaped glasses

- Straight edges and radii – both possible

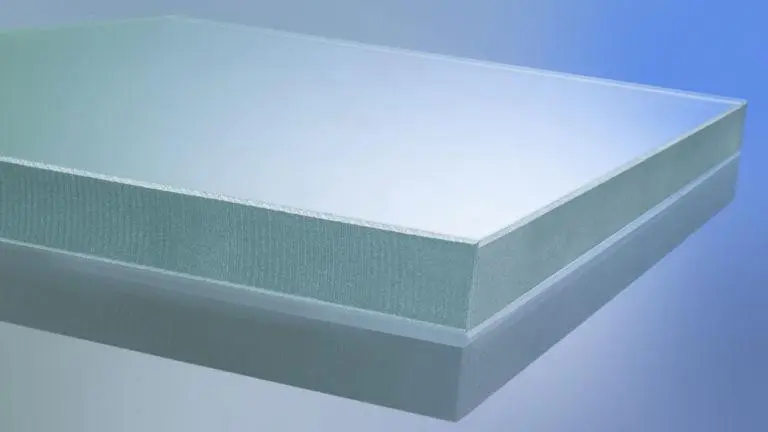

- Float glass, tempered glass and laminated glass

2.

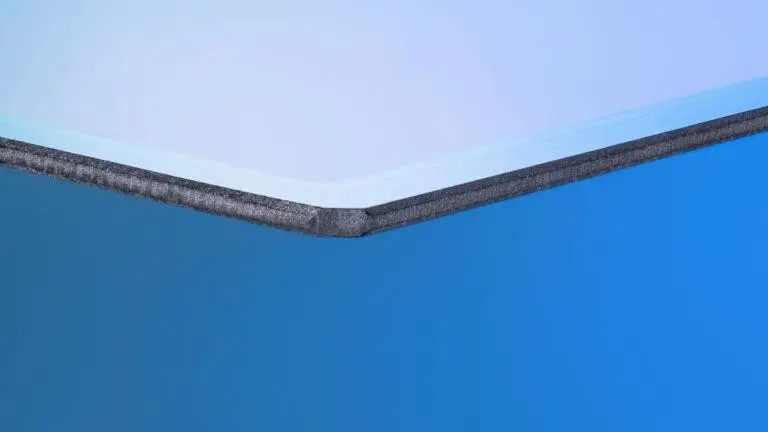

Homogeneous and uniform arrissing quality

- Edge arrissing

- Flat edge arrissing

- Corner dubbing

3.

Economical and accurate production

- Highest process speed up to 60 m/min (edge and flat edge)

- Low cycle times & operating costs

- No tool change with the cup wheel technology

MULTI'ARRISSER

Automatic vertical arrissing machine

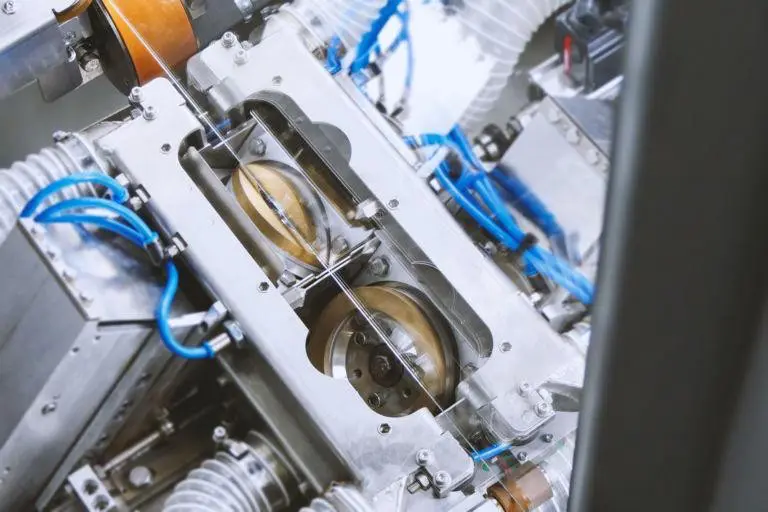

Homogeneous and uniform arrissing quality even at the beginning and the end

- Best arrissing quality through the use of cup wheels.

- Compared to profiled wheels, the contact surface to the glass with cup wheels is much higher.

- Material removal is distributed over several diamonds and thus becomes more even.

Highest arrissing speed

- The cup wheels allow a maximum arrissing speed of 60m/min (also for flat edge).

- With these speed the MULTI’ARRISSER is the fastest single-head-machine worldwide.

No tool change necessary

- Always the same cup wheels are used for different glass plate thicknesses and different functions.

One cup wheel for multiple functions

- Different glass thickness from 3 mm to 25 mm

- Different functions such as edge, flat side, corner dubbing are realized with the same cup wheel

- No loss of production time in mixed operation

- Only one wear part

- Best price/performance ratio for the tool due to simplest geometry

Long lifetime of arrissing tool

- 5 to 10 times higher lifetime for glass edge arrissing than all other arrissing systems

- Higher productivity due to higher uptime

- Less service interventions due to less shutdown time

- Possible cost reduction within a shortest period of time due to longer lifespan of the tools

References

Euroglas, Belgium

#flat glass tempering #glass tempering #iControL #RHC #safety glass #tempered glass #upgrades

Euroglas chose Glaston’s Roller Heat Control (RHC) upgrade to improve its tempering line performance as part of a series of investments to grow with its customers. “We aim to offer the width and depth of glass products they need to be their best partner,” says Frederik De Knijf, CEO of Euroglas in Belgium.

Read morePilkington Automotive Finland, Finland

#automotive glass #automotiveindustry #CNC #CNC96 #lifecycleservices #mobility #reference #upgrades

“We decided to extend the lifetime of our Bystronic (now Glaston) automotive glass cutting equipment with a Glaston CNC96 upgrade kit and ensure that we can continue to get spare parts,” says Matti Säynäväjärvi, Technical Services Group Leader, Pilkington Automotive Finland Oy, Laitila plant.

Read moreViridian Glass, Australia

#architectural #automation #COMFORT #glass quality #IG unit #insulating glass #reference

As building regulations require more energy-efficient glass, Viridian Glass has stepped up its game. Purchasing Glaston’s COMFORT BOX IG manufacturing line enables its Woodville plant in Adelaide to meet burgeoning demands with visibly better quality and shorter lead times. “High quality insulated glass is the future in Australia,” says, National Operational Excellence Manager, Tarun Bhatia at Viridian Glass.

Read moreArticles

Does turning a tempering furnace off really save energy?

Some manufacturers suggest you can save energy by heating the furnace from room temperature in just one hour at the start of each shift. Does this approach actually...

Read moreTempering energy-consumption claims – don’t fall for them

Modern tempering technologies bring glass processors significant energy efficiencies. However, some tempering line manufacturers make energy-saving claims that sound...

Read moreBreakthroughs in automating glass processing

From traditional applications to cutting-edge capabilities, automation revolutionizes production, enhances quality and boosts efficiency. In this blog, we’ll discuss...

Read more