TPS® – Thermo Plastic Spacer

Trust the original from the inventor

Sustainable, efficient and durable.

1.

Designed with a focus on usability, adjustability and efficiency

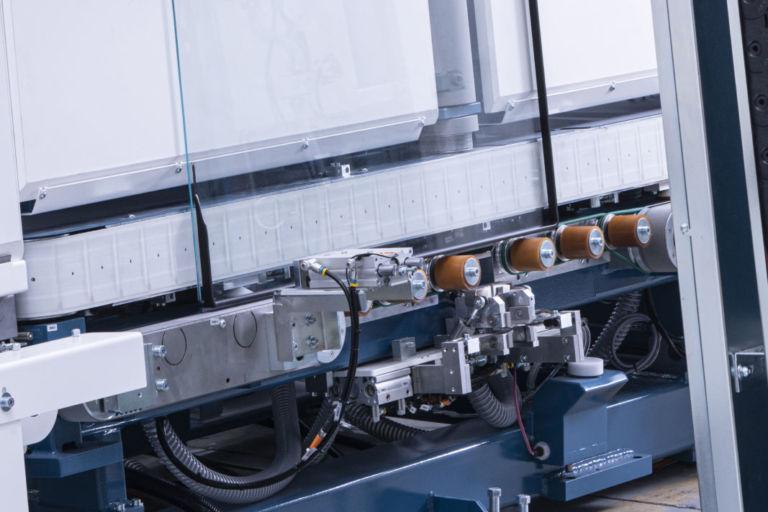

- TPS® production line is the most advanced and flexible solution for insulating glass manufacturing and allows applying the thermoplastic spacer material directly onto the glass plate

- Increased production capacity and higher output

- Flexible settings and versatile options

- Production process can be customized

- Even mixed production can be flexibly manufactured on a single line in an endless mode – without any loss of time.

2.

Boost your operation

- Production increase by decreasing cycle times with innovative parallel transportation of glass plates

- Exclusive gear pump system for high material dosing accuracy and application quality

- Double material feed through master-master drum pump

- Automatic IG thickness adjustment for compensating glass thickness tolerances

- Easy-to-use drum trolley system for a simple drum change in less than 3 minutes

3.

Premium insulating glass

- TPS® is well proven with several million IG units installed and is suitable for residential as well as commercial buildings

- Especially versatile for structural glazing, fire-resistant and noise-protecting glass as well as for glazing vehicle and train glass

- Excellent tension, expansion and resilience properties

- Optimal sealing barrier against gas loss

- Homogeneous, continuously applied Thermo Plastic Spacer TPS® –

the perfect primary seal

New drum trolley system

- TPS® features a new drum trolley system

- The trolley system enables a simple drum change in less than three minutes. The same process takes around 10 minutes for alternative solutions

- Easy to use, the new drum trolley system requires only four actions from the operator: unlock, lift, replace, lock

- No need for heavy lifting, eliminating risks to operator health and safety

Bevel joint

- Glaston can now address individual customer needs and position the bevel joint in every corner, which makes it almost invisible

- The bevel joint positioning on the glass side is also possible

- It is suitable for all glass formats and spacer widths between 4 and 20 mm

- Unlike other solutions on the market, Glaston’s bevel joint doesn’t require any thermal-mechanical reworking or finishing processes

- Irrespective of radii, small or large airspaces between the glass units, Glaston’s bevel joint ensures the highest gas tightness

- When installed in a window frame, it makes the final aesthetic appearance admirable

And more...

References

Glas Dreisbusch, Germany

#architectural #IG unit #insulating glass #reference #TPS #VARIO

“The idea of a special U-shaped design to fit our confined space was created over lunch by my son Maximillian Dreisbusch and two Glaston service engineers. I think this says everything about our close and collaborative partnership with Glaston,” says Thomas Dreisbusch, Managing Director of Glas Dreisbusch.

Read moreNortheast Building Products, U.S.A.

#architectural #glass processing #IG unit #insulating glass #reference #TPS #VARIO

With over 650 employees, Northeast Building Products, based in Philadelphia PA, USA, manufactures high quality, energy efficient windows, doors and ancillary products for the residential window and door market. Alan Levin, President of NBP, has partnered with Bystronic glass since 2009 when they invested in the cutting edge Sashlite™ technology, SashLine, to support the company’s diversification and growth strategy.

Read moreMetro Performance Glass, New Zealand

#architectural #glass processing #IG unit #insulating glass #JUMBO #reference #TPS

Bystronic glass once again achieved great success after the commissioning and installation of a new B’JUMBO I.G. line in Auckland, New Zealand. The progressive project is part of an expansion phase at one of Australasia’s leading glass processors – Metro Performance Glass.

Read moreArticles

Breakthroughs in automating glass processing

From traditional applications to cutting-edge capabilities, automation revolutionizes production, enhances quality and boosts efficiency. In this blog, we’ll discuss...

Read moreKey applications of automation in glass processing

What glass processes gain the most from automation? In this blog, we’ll focus on some of the particularly promising application areas. As we discovered in the...

Read moreWhy embrace glass processing automation?

When finding, training and retaining personnel for routine jobs is a challenge, processing automation offers a game-changing solution. But other drivers are also...

Read more