Al-Manna, Saudi Arabia

Reference - Middle East & Africa

Glaston’s Jumbo and FC Series lines set Al-Manna apart from the rest

“Our aim is to achieve the highest level of perfection with the glass we provide to the booming market in Saudi Arabia,” says Mr. Ibrahim and Mr. Dafeer Manna Al-Amri, who head up Al-Manna Glass in the country’s capital of Riyadh.

Al-Manna is no stranger to Glaston. Established in 1952 by the father of Ibrahim and Dafeer, the company began its journey as a pioneer of high-quality tempered glass in the Middle East. Now 70 years later, with 35 branches of glass processing and mirror factories, Ibrahim and Dafeer carry on the legacy of delivering only the very best.

Al-Manna has been a leader in the field throughout its seven decades, thanks to the top-class glass processing machinery it has chosen along the way. From early on, the company selected the highest-quality equipment from Glaston and other European technology.

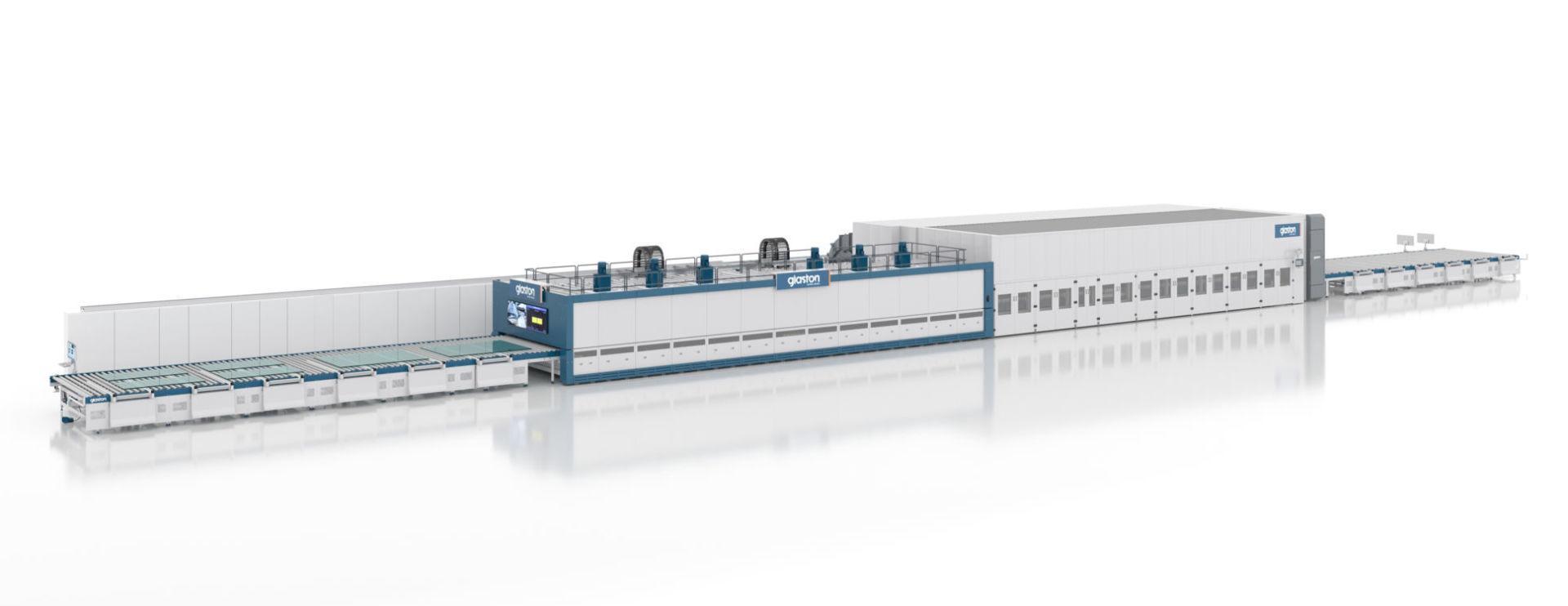

“We’re still taking full advantage of the two FC Series tempering lines with the Chinook convection technology we bought from Glaston in 2014,” says Ibrahim. “And the latest innovations in Glaston’s tempering technology led us to invest in the Jumbo Series tempering line, which was commissioned and ready to run in the spring of 2022. We also purchased the latest FC Series line, which was delivered in the middle of this year, to produce coated 6-mm glass for double-glazing units.”

The latest Glaston Jumbo Series tempering line with the unique Fusion option offers scalability and a modular design to meet varying business needs. It can easily switch between single- and double-chamber modes when needed. This saves energy costs and allows a mixed load of two kinds of glass in the same batch to meet requirements for laminated and gapless (vacuum) glass, boosting production efficiency.

Glaston FC Series enables Al-Manna to produce fire-rated glass, which makes it only the second company in the world after one in the UK with this capability. This enables the company to meet the new high-quality regulations from the Saudi government to isolate homes and hotels from the spread of fire. When on fire, the glass remains as a single panel for 120 minutes without collapse. This helps save residents’ lives and contributes to energy savings.

“We’re working very hard to develop our offering, as customers are keen to get the best quality. With the Jumbo Series, we’ll be able to meet the requirements of extra-large glass, which is now in high demand, with a large production capacity. Architects and owners alike prefer the larger sizes for everything now – from facades to high-rise buildings. This trend has empowered us to purchase the Jumbo furnace from Glaston to stay ahead in our market.”

Similar references

Euroglas, Belgium

#flat glass tempering #glass tempering #iControL #RHC #safety glass #tempered glass #upgrades

Euroglas chose Glaston’s Roller Heat Control (RHC) upgrade to improve its tempering line performance as part of a series of investments to grow with its customers. “We aim to offer the width and depth of glass products they need to be their best partner,” says Frederik De Knijf, CEO of Euroglas in Belgium.

Read morePilkington Automotive Finland, Finland

#automotive glass #automotiveindustry #CNC #CNC96 #lifecycleservices #mobility #reference #upgrades

“We decided to extend the lifetime of our Bystronic (now Glaston) automotive glass cutting equipment with a Glaston CNC96 upgrade kit and ensure that we can continue to get spare parts,” says Matti Säynäväjärvi, Technical Services Group Leader, Pilkington Automotive Finland Oy, Laitila plant.

Read moreViridian Glass, Australia

#architectural #automation #COMFORT #glass quality #IG unit #insulating glass #reference

As building regulations require more energy-efficient glass, Viridian Glass has stepped up its game. Purchasing Glaston’s COMFORT BOX IG manufacturing line enables its Woodville plant in Adelaide to meet burgeoning demands with visibly better quality and shorter lead times. “High quality insulated glass is the future in Australia,” says, National Operational Excellence Manager, Tarun Bhatia at Viridian Glass.

Read moreArticles

Does turning a tempering furnace off really save energy?

Some manufacturers suggest you can save energy by heating the furnace from room temperature in just one hour at the start of each shift. Does this approach actually...

Read moreTempering energy-consumption claims – don’t fall for them

Modern tempering technologies bring glass processors significant energy efficiencies. However, some tempering line manufacturers make energy-saving claims that sound...

Read moreBreakthroughs in automating glass processing

From traditional applications to cutting-edge capabilities, automation revolutionizes production, enhances quality and boosts efficiency. In this blog, we’ll discuss...

Read more