Dr. Greiche Glass, Egypt

Reference - Middle East & Africa

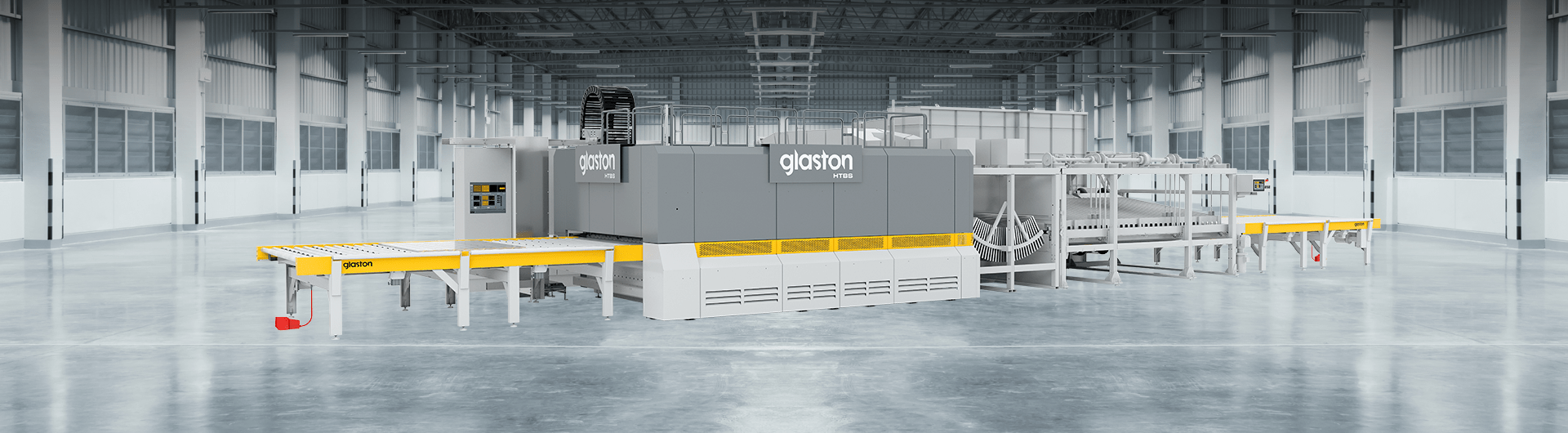

Dr. Greiche Glass buys another furnace from Glaston

“Our definition of glass has changed over the years – from a simple see-through, solid material to a high-performance smart product,” says Mohamed Ezz El-Din, Technical Department Manager at DG Glass. “That’s why we have had to change too. Today, we’re investing in new technologies like Glaston’s HTBS bending and tempering furnace to change the definition of automotive glass we’re bringing to the market.”

Dr. Greiche Glass (DG Glass) has grown from being established in automotive glass in 1985 to presently running six top-quality production facilities with over 1,600 employees.

Headquartered in the city of 10th of Ramadan, near Cairo, DG Glass is the leading glass processor in the Middle East and Africa and is the main glass supplier for all car manufacturers in Egypt.

At the end of 2016, DG Glass commissioned the new HTBS bending and tempering furnace from Glaston to help the company increase its production capacity for glass products to serve both passenger cars and bus manufacturers.

The company’s relationship with Glaston dates back to 1992, when the first bending and tempering line for sidelites was ordered. DG Glass has several Glaston furnaces. One of the previous investments included Glaston Matrix, a modern windshield bending furnace, commissioned in 2016, along with the new HTBS.

“Glaston’s HTBS bending and tempering furnace is well known in the market for its flexibility and high end-product quality. This is exactly what we were looking for to meet the growing requirements of the modern automotive market. And indeed, it allows us to be more creative when needed.”

Similar references

FLACHGLAS, Germany

#flat glass laminating #glass processing #glass quality #laminated glass #laminating #ProL #ProL-zone #quality control #reference #safety glass #upgrades

At FLACHGLAS, a culture of operational excellence fuels continuous modernizations. “The latest Glaston ProL upgrade for our 50-year-old lamination line has helped us raise performance, save energy and automate production with the push of a button,” says Martin Geiss, Technical Manager at FLACHGLAS Wernberg.

Read moreFull Glass, Peru

#architectural #automation #flat glass tempering #glass tempering #glass tempering process #iControL #RC Series #reference #tempered glass

“We are very satisfied with the quality of our new RC Series tempering line and the glass it produces. The Vortex Pro convection control system is excellent. The furnace made by Glaston China is just as well manufactured as the previous furnace we bought from Glaston’s factory in Finland,” says Frank Calderón Gómez, Managing Director at Full Glass in Lima, Peru.

Read moreAGC Interpane, Germany

#architectural #automation #glass processing #IG unit #insulating glass #reference #technology

“I walk through our insulating glass production facility every day with pride,” says Daniel Bruckelt, Production Manager Insulating Glass of AGC Interpane in Plattling, Germany. “Not just because everything is so well organized and structured, but also because Glaston has given us a coherent concept for our unique insulating glass (IG) production. And this is what allows us to remain top-of-mind for challenging world-class projects.”

Read moreArticles

GPD 2023 Presentations – Sustainability and trends

The Glass Performance Days 2023 conference brought forward a compelling array of presentations focused on sustainability and emerging trends within the glass industry....

Read moreGPD 2023 Presentations – Glass processing technologies

The Glass Performance Days 2023 conference showcased a range of pioneering presentations on glass processing technologies, bringing together industry leaders and...

Read moreGPD 2023 Presentations – Architectural glass

The Glass Performance Days 2023 conference has once again brought together a wealth of knowledge and innovation from the leading minds in the glass industry. We...

Read more