Virtual Engineer

As if we were on site with you – but much faster

Three reasons to use Virtual Engineer

1.

Quick availability

- Quick availability of technicians

- Senior-level specialists from our Technology Centers will advise and support your workforce on site using a Microsoft HoloLens 2 mixed reality headset

2.

Warranty included

- Warranty for the work performed

- Clear documentation of all interventions

3.

Cost savings and other advantages

- Savings of 10–40% per intervention

- Modular system of available services

- Access to previous jobs and relevant documentation

- Can also be used for internal training purposes

Simple, fast, efficient

Sometimes, it simply has to be done quickly before major damage or long downtime occurs. Now, you can easily carry out service work or spare parts installation yourself – under the live guidance of our experts.

Our mixed reality-based support

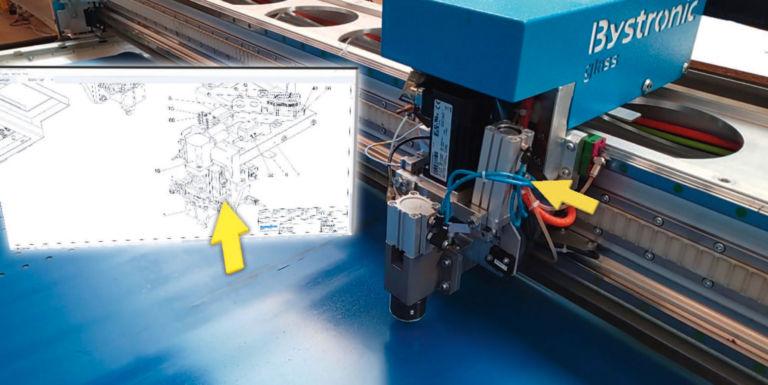

Using mixed reality, you have everything where you need it

- Marking objects with arrows in real time

- Integrated documents, instructions and technical drawings

- Live values from the controller or control panel

- Photo or video recording capability

Visual support for better understanding

- Virtual laser pointer clarifies what is being discussed

- Text and video chat functions with our engineers

- Support in English, German and Finnish

Reliable technology provided by Microsoft Teams

- Easy project planning

- Simple data exchange and full control of all your data

- Video conferencing

- Libraries

- Easy collaboration

Choose your individual solution

| Our services | Case to case | Contract |

| Mobile app use | • | • |

| HoloLens use | • | • |

| HoloLens use for hotline support | - | • |

| Number of HoloLens users | 1 (one case per month) | 2 |

| Warranty for work performed | •* | •* |

| Access to the Microsoft Teams platform | 1 (one case per month) | 2 |

| Use for internal purposes | - | Yes |

| Flat-rate support | - | Yes |

| VPN Care use included | - | Yes |

| Costs | Cost per hour | Fixed cost per year |

* = Preconditions for warranty

- Only valid for the continuous use of HoloLens

- Applies as long as the instructions of the Virtual Engineer are strictly followed

- Requires session recording

Service contracts are always the better choice

- We provide you with individual, customized contracts

- Our services are scalable depending on your machinery and requirements

- Additional users are also possible

References

Lippert Components, USA

#automation #automotive #automotive glass #bending #CHAMP #CHF #glass bending #glass tempering #Matrix #reference #safety glass

Tim Widner at Lippert Components in the US is sharing his and his team's experiences working with the Glaston glass processing machinery. "The new equipment has been a great addition to us. We are able to one-piece flow our raw material through our line, hands-free. No humans come in contact with the glass until it is fully tempered and at the end of the process."

Read moreParagon Tempered Glass, U.S.A.

#automation #automotive #automotive glass #CHAMP #glass processing #Matrix #pre-processing #thin glass #windshield

“When we saw the CHAMP 25 a few years ago, we knew this was the future we should pursue for our next round of capital expenditures,” says Dan Wright, CEO of Paragon Tempered Glass.

Read moreLong Nhien, Vietnam

#automotive #automotive glass #bending #glass bending #Matrix #reference #windshield

“The market in Vietnam for cars is very large with lots of room for growth. People are becoming wealthier, and sitting in a car is more comfortable than being on a scooter, which may be prohibited in the next few years,” says Nguyen Phuong Tran, Production Manager, and son of Long Nhien Automotive Glass’s owners, about his home market. “The Glaston Matrix windshield bending furnace is a stepping stone for us to tap into this rapidly expanding business of hundreds of thousands new cars per year.”

Read moreArticles

GPD 2023 Presentations – Sustainability and trends

The Glass Performance Days 2023 conference brought forward a compelling array of presentations focused on sustainability and emerging trends within the glass industry....

Read moreGPD 2023 Presentations – Glass processing technologies

The Glass Performance Days 2023 conference showcased a range of pioneering presentations on glass processing technologies, bringing together industry leaders and...

Read moreGPD 2023 Presentations – Architectural glass

The Glass Performance Days 2023 conference has once again brought together a wealth of knowledge and innovation from the leading minds in the glass industry. We...

Read more