Upgrade Kit – CNC96 Retrofit

Retrofit your existing glass cutting equipment with proven Glaston OEM upgrade kits

1.

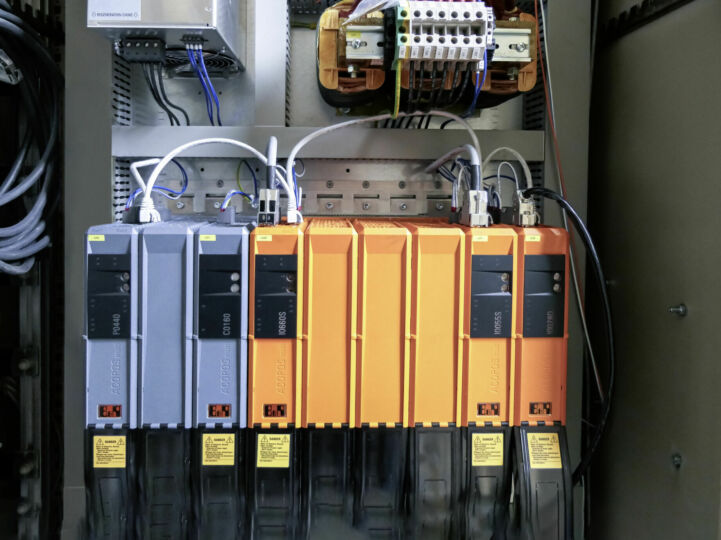

CABINET CONVERSION

- Time-saving, pre-installed and pre-tested back planes as complete units to be changed

- Reuse of existing cabinet and connection cables

- Line control connection remains in place

- Safety concept according to current regulations

- Heavy parts on back planes are easily detachable, no crane needed

2.

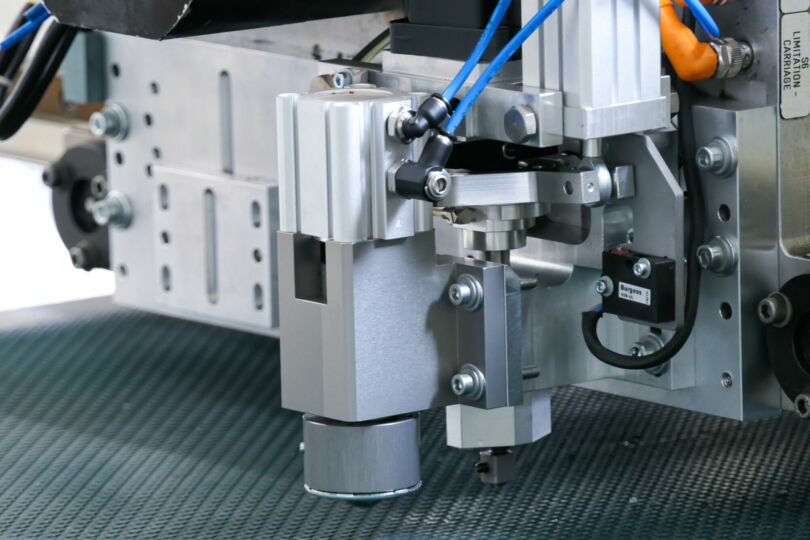

KSBM DIRECT CONTROLLED CUTTING TOOL UPGRADE

- Higher cutting accuracy and more precise radius at process start and finish

- Significantly reduced glass grinding allowance

- Reduced cycle time and increased grinding wheel life

- Cutting path is simple to program

- Reduction of wear parts

- Repeatable cutting accuracy of ± 0.1 mm

- Highly precise cutting force adjustability, even for lowest ranges

3.

ACS STATE-OF-THE-ART CN CONTROL

- Microsoft® Windows 10 operating system

- Touch screen control

- Ready for Glaston digital service offerings and OPC UA interface

- Multiple languanges supported

- Access to network folder for job management

- Same look and feel as latest Glaston machine generation

- Option to transfer line control to new operator desk

Back to strength with state-of-the-art CN control

It is now possible to retrofit your existing former Bystronic glass automotive and architectural glass cutting equipment using a CNC96 control with a state-of-the-art CN control including most modern features.

CNC96 is an in-house system engineered with exclusively developed hardware components used from 1996 until 2010. Avoid any risks as from 2025 many components are coming to the end of their life and replacements won’t be possible anymore.

Glaston’s cost-efficient CNC96 upgrade kit is a proactive step to extend the lifetime of your processing equipment and to ensure uninterrupted performance. It includes the latest advances in automation to keep your operations running with steady, high-quality yield and gain from the most up-to-date improvements.

- Entire upgrade requires minimal component replacement and can be performed cost effectively in as few as 3 to 5 working days

- Complete hardware kits are ready for immediate delivery

- Comprehensive support and continued long-term availability of spare parts

- ACS state-of-the-art CN control with most modern features

- Future maintenance costs are lowered

References

Lippert Components, USA

#automation #automotive #automotive glass #bending #CHAMP #CHF #glass bending #glass tempering #Matrix #reference #safety glass

Tim Widner at Lippert Components in the US is sharing his and his team's experiences working with the Glaston glass processing machinery. "The new equipment has been a great addition to us. We are able to one-piece flow our raw material through our line, hands-free. No humans come in contact with the glass until it is fully tempered and at the end of the process."

Read moreParagon Tempered Glass, U.S.A.

#automation #automotive #automotive glass #CHAMP #glass processing #Matrix #pre-processing #thin glass #windshield

“When we saw the CHAMP 25 a few years ago, we knew this was the future we should pursue for our next round of capital expenditures,” says Dan Wright, CEO of Paragon Tempered Glass.

Read moreLong Nhien, Vietnam

#automotive #automotive glass #bending #glass bending #Matrix #reference #windshield

“The market in Vietnam for cars is very large with lots of room for growth. People are becoming wealthier, and sitting in a car is more comfortable than being on a scooter, which may be prohibited in the next few years,” says Nguyen Phuong Tran, Production Manager, and son of Long Nhien Automotive Glass’s owners, about his home market. “The Glaston Matrix windshield bending furnace is a stepping stone for us to tap into this rapidly expanding business of hundreds of thousands new cars per year.”

Read moreArticles

GPD 2023 Presentations – Sustainability and trends

The Glass Performance Days 2023 conference brought forward a compelling array of presentations focused on sustainability and emerging trends within the glass industry....

Read moreGPD 2023 Presentations – Glass processing technologies

The Glass Performance Days 2023 conference showcased a range of pioneering presentations on glass processing technologies, bringing together industry leaders and...

Read moreGPD 2023 Presentations – Architectural glass

The Glass Performance Days 2023 conference has once again brought together a wealth of knowledge and innovation from the leading minds in the glass industry. We...

Read more