Spacer bending

Excellent bending quality and high dimensional accuracy for all common profile types

Here are three reasons why Glaston’s spacer bending plants are your best choice

1.

Excellent bending quality thanks to special bending technology

2.

High measurement accuracy due to precision-guided profile conveyor

3.

Ideal for operations with a separate subsequent filling station

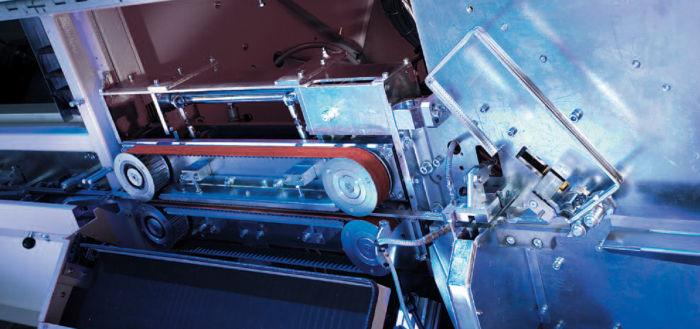

SPACER’BENDER Type RB-AL

A basic spacer-bending robot designed specifically for spacers made of aluminum

- Efficient bending equipment for processing unfilled aluminum profiles

- No tool change required for profile widths of 8–24 mm

- Processes plastic profiles

- Optimization with simultaneous saw cutting and bending of the fourth corner

- Storage for two spacer bar bundles

- Material savings and work made easier thanks to endless spacer bar connection

- Integrated assembly tool for finishing the last joint

Options

- Rotation magazine for eight profile widths or types with residual recovery

- Product labeling with inkjet printer

- Integrated drilling station for manual gas filling

SPACER’BENDER Type RB-EST

A combined spacer-bending robot designed specifically for warm edge spacer systems

- Fully flexible with combined bending equipment for two-way alternate processing of various materials

- Particularly suitable for hollow plastic profiles as well as web profiles made of stainless steel

- Over-bending possible for all corners

- Tools for aluminum and various other plastic profiles independent of spacer width

- Direct access to the bending tool enables quick changeover

- Rotation magazine for eight profile widths or types with residual recovery

- Material savings and work made easier thanks to endless spacer bar connection

- Integrated assembly tool for finishing the last joint

- Double-head profile saw for a variety of materials

Options

- Product labeling with inkjet printer

- Integrated drilling station for manual gas filling