Press Glass Inc., U.S.A.

Reference - Americas

Bringing European expertise to high-quality US glass production

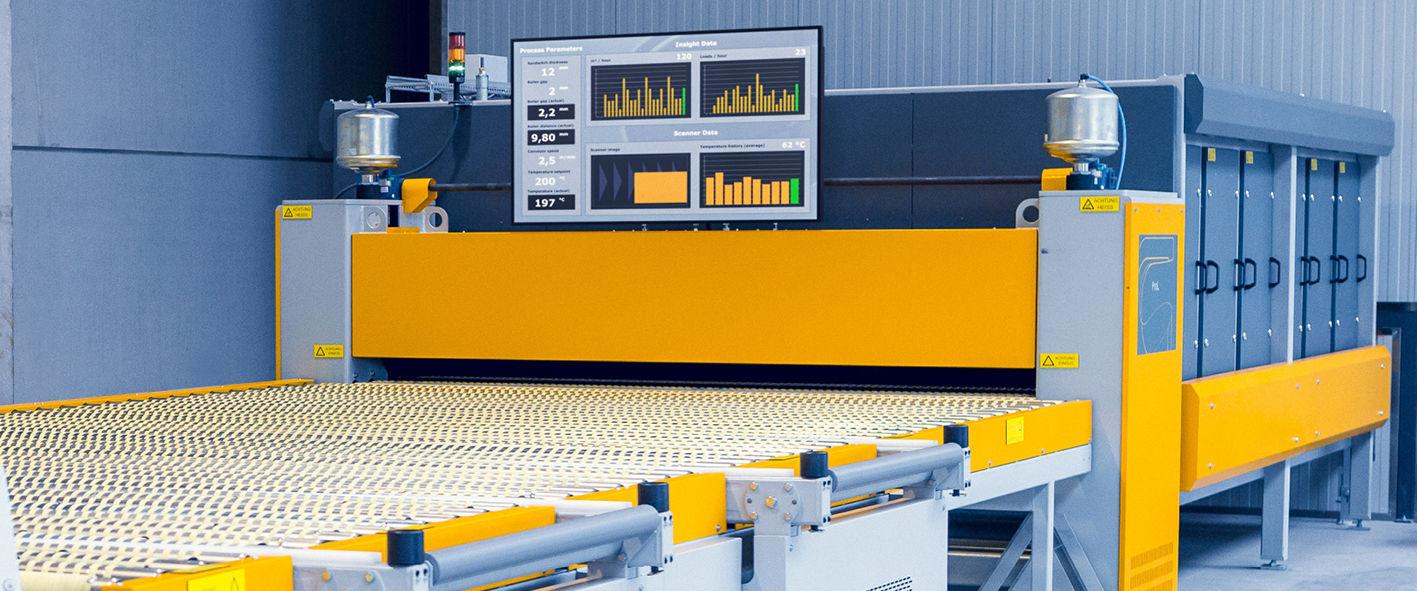

Since establishing their presence in the US through an acquisition, Poland-based Press Glass has continued its brisk growth based on the same values that make it the #1 glass fabricator in Europe and the UK. The company’s latest US investment is a Glaston ProL convection control upgrade at its Ridgeway, Virginia, plant.

Bringing European expertise to high-quality US glass production

Glaston and Press Glass share a longstanding partnership. Most of the tempering lines in Press Glass’s European facilities are from Glaston. The company’s US branch has Glaston FC Series and Jumbo Series tempering lines at the Ridgeway factory for larger projects and an additional smaller line in Stoneville for smaller IG units and heavier interior glass. Currently, a fourth line – another tempering furnace – is being assembled and will be delivered soon.

“Glaston is considered the ‘Cadillac’ of the market. The price point may be higher, but a Glaston machinery lasts longer and produces higher quality,” says Gregg Vanier, Director of Manufacturing and Technology at Press Glass.

In another move forward, Press Glass was the first in the world to invest in Glaston’s convection upgrade for its lamination line in Ridgeway, completed in April 2023.

“It was clear we needed to upgrade when the market started asking for more complex end products. We needed better control to help process the multilayer laminates that are more common in the US market than the monolayers in Europe,” Gregg explains.

The ProL convection upgrade helps eliminate trapped air inside the layers that causes a lack of adhesion.

“Since commissioning, we have been able to gain traction in the market. We just had our most efficient production period in terms of square footage produced per day. The upgrade also led to higher quality, enabling us to reach 98% on-time delivery.”

Similar references

Lippert Components, USA

#automation #automoti #automotive glass #B'CHAMP #Bending #CHF #glass bending #glass tempering #Matrix #reference #safety glass

Tim Widner at Lippert Components in the US is sharing his and his team's experiences working with the Glaston glass processing machinery. "The new equipment has been a great addition to us. We are able to one-piece flow our raw material through our line, hands-free. No humans come in contact with the glass until it is fully tempered and at the end of the process."

Lue lisääEmirates Glass, UAE

#architectural #automation #Flat tempering #glass tempering #iLooK #Jumbo Series #reference #safety glass #tempered glass

Emirates Glass LLC, one of the leading organizations in the glass industry and a long-time advocate of Glaston technology, continues its journey of innovation and quality enhancement with the installation of the Glaston Jumbo Series flat glass tempering line featuring Vortex Pro convection technology. This investment marks Emirates Glass’s commitment to delivering top-notch architectural glass solutions to the region and far beyond.

Lue lisääArticles

GPD 2023 Presentations – Sustainability and trends

The Glass Performance Days 2023 conference brought forward a compelling array of presentations focused on sustainability and emerging trends within the glass industry....

Lue lisääGPD 2023 Presentations – Glass processing technologies

The Glass Performance Days 2023 conference showcased a range of pioneering presentations on glass processing technologies, bringing together industry leaders and...

Lue lisääGPD 2023 Presentations – Architectural glass

The Glass Performance Days 2023 conference has once again brought together a wealth of knowledge and innovation from the leading minds in the glass industry. We...

Lue lisää