COMPACT & COMFORT

Start-up solutions in automated insulating glass production

Looking to start automated insulating glass production?

Here are three reasons why Glaston COMPACT and Glaston COMFORT are your best choice

1.

Up to 800 gas-filled insulating glass units per shift

2.

Low investment costs

3.

Compact line layout

The Glaston COMPACT and Glaston COMFORT provide high quality I.G. unit manufacturing with an excellent cost/performance ratio – optional with gas filling by Glaston COMFORT.

In addition to the proven quality and reliability, these I.G. lines offer real added value.

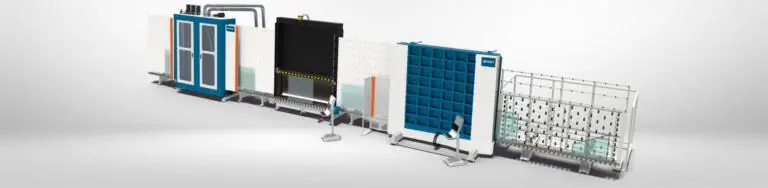

COMPACT

Your entry into the world of insulating glass manufacturing.

Double-sided spacer frame coating with thermoplastic sealants

Coated glass plate edge deletion

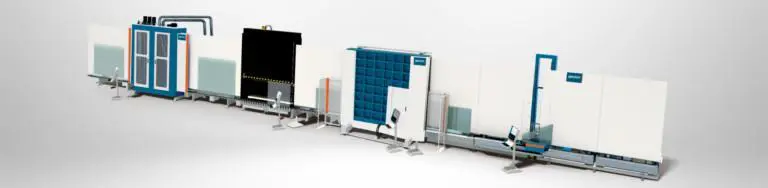

COMFORT

Your entry into the world of insulating glass manufacturing with automated gas filling.

Continuous washing and drying of diverse glass plates

Visual glass inspection and manual positioning of spacer frames

Automatic assembling, gas filling and pressing of I.G. units

Continuous sealing of I.G. units of different formats and dimensions

References

Viridian Glass, Australia

#architectural #automation #COMFORT #glass quality #IG unit #insulating glass #reference

As building regulations require more energy-efficient glass, Viridian Glass has stepped up its game. Purchasing Glaston’s COMFORT BOX IG manufacturing line enables its Woodville plant in Adelaide to meet burgeoning demands with visibly better quality and shorter lead times. “High quality insulated glass is the future in Australia,” says, National Operational Excellence Manager, Tarun Bhatia at Viridian Glass.

Read moreAGC Interpane, Germany

#architectural #automation #glass processing #IG unit #insulating glass #reference #technology

“I walk through our insulating glass production facility every day with pride,” says Daniel Bruckelt, Production Manager Insulating Glass of AGC Interpane in Plattling, Germany. “Not just because everything is so well organized and structured, but also because Glaston has given us a coherent concept for our unique insulating glass (IG) production. And this is what allows us to remain top-of-mind for challenging world-class projects.”

Read moreGlas Dreisbusch, Germany

#architectural #IG unit #insulating glass #reference #TPS #VARIO

“The idea of a special U-shaped design to fit our confined space was created over lunch by my son Maximillian Dreisbusch and two Glaston service engineers. I think this says everything about our close and collaborative partnership with Glaston,” says Thomas Dreisbusch, Managing Director of Glas Dreisbusch.

Read moreArticles

Breakthroughs in automating glass processing

From traditional applications to cutting-edge capabilities, automation revolutionizes production, enhances quality and boosts efficiency. In this blog, we’ll discuss...

Read moreKey takeaways from glasstec 2024

Held in late October, glasstec 2024 buzzed with energy, robotic solutions and serious discussions. Based on what we saw and heard at the event, we can outline a...

Read moreKey applications of automation in glass processing

What glass processes gain the most from automation? In this blog, we’ll focus on some of the particularly promising application areas. As we discovered in the...

Read more