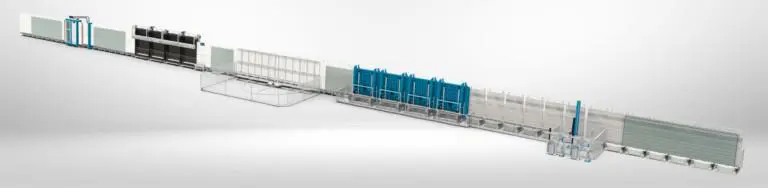

JUMBO & JUMBO XXL

The system solution for maximum requirements

Looking to aim big?

Here are three reasons why Glaston JUMBO and Glaston JUMBO XXL are your best choice

1.

Insulating glass units

up to 600 kg/m

2.

Maximum glass size

3.3 x 18 m

3.

“Green production” with optimum energy efficiency

JUMBO & JUMBO XXL

Impressive insulating glass manufacturing in maximum size

Glaston JUMBO and Glaston JUMBO XXL are insulating glass lines specially designed for manufacturing large-sized insulating glass units and façade elements up to 18 m in length.

- Up to 600 kg per running meter with heavy unit capability

- Optimized insulating glass line energy efficiency

Edge deletion of jumbo units in rectangular and shaped formats

Automatic positioning and pressing of the upper frame edge

Automatic turning of coated glass plates up to 12 m in length

Automatic assembling, gas filling and pressing of up to four-sided stepped jumbo units

Continuous sealing of up to four-sided stepped jumbo units with up to 30 mm sealing depth

References

Viridian Glass, Australia

#architectural #automation #COMFORT #glass quality #IG unit #insulating glass #reference

As building regulations require more energy-efficient glass, Viridian Glass has stepped up its game. Purchasing Glaston’s COMFORT BOX IG manufacturing line enables its Woodville plant in Adelaide to meet burgeoning demands with visibly better quality and shorter lead times. “High quality insulated glass is the future in Australia,” says, National Operational Excellence Manager, Tarun Bhatia at Viridian Glass.

Read moreAGP, New Zealand

#architectural #automation #autopilot #digitalization #FC Series #flat glass tempering #reference

“We’re now running with the stability, reliability and consistency we aimed to achieve when we invested in Glaston’s Autopilot,” David Bunting, Managing Director of Architectural Glass Products (AGP), says.

Read moreVitropor, Portugal

#architectural #automation #flat glass laminating #flat glass tempering #glass processing #glass tempering #iControL #laminating #ProL #reference #RHC #safety glass #tempered glass #upgrades

“When we buy a new TV or piece of furniture for our home, it gives us good vibes – a nice feeling. In a similar way, we chose to upgrade our tempering furnace to make things easier and better for our team, so their work would be more enjoyable,” says Pedro Aguilar, Managing Director of Vitropor.

Read moreArticles

Breakthroughs in automating glass processing

From traditional applications to cutting-edge capabilities, automation revolutionizes production, enhances quality and boosts efficiency. In this blog, we’ll discuss...

Read moreKey applications of automation in glass processing

What glass processes gain the most from automation? In this blog, we’ll focus on some of the particularly promising application areas. As we discovered in the...

Read moreWhy embrace glass processing automation?

When finding, training and retaining personnel for routine jobs is a challenge, processing automation offers a game-changing solution. But other drivers are also...

Read more