SPEED

The benchmark in triple and quadruple insulating glass manufacturing using conventional, flexible and TPS® spacers

Looking for the fastest possible insulating glass production?

Here are three reasons why Glaston SPEED is your best choice

1.

Produce triple units in the same time other lines produce double units

2.

Ideally designed work steps

3.

Choose between conventional, flexible or TPS® spacers

Glaston SPEED is a quick insulating glass manufacturing line that produces triple and quadruple units in the fastest possible cycle times. It is available in the following variants:

SPEED BOX

Fastest insulating glass manufacturing using conventional spacers

Quick, synchronized gas filling of both spaces between triple insulating glass units

Dynamic quality sealing at the maximum flow rate and highest speed application

Shortest cycle times thanks to parallel filling and transporting operations

Precise, automatic spacer frame butyl coating

SPEED FLEX

Fastest insulating glass manufacturing using flexible spacers from the reel

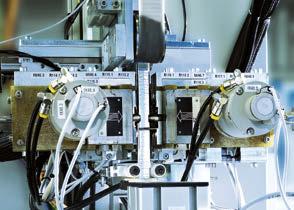

Twin-head applicator for interruption-free insulating glass production with different spacer widths

Processing of flexible spacers with double-sided polyisobutylene application

SPEED TPS®

Fastest insulating glass manufacturing using TPS®

Direct application of the Thermo Plastic Spacer (TPS®) onto the glass plate. The spacer width can be changed as desired during operation without any time loss

The dual-drum pump system enables completely interruption-free operation. The material drum change takes place during production

Possibility of individual product identification according to local regulations.