Armour Sealed Units Ltd., UK

Reference - Europe

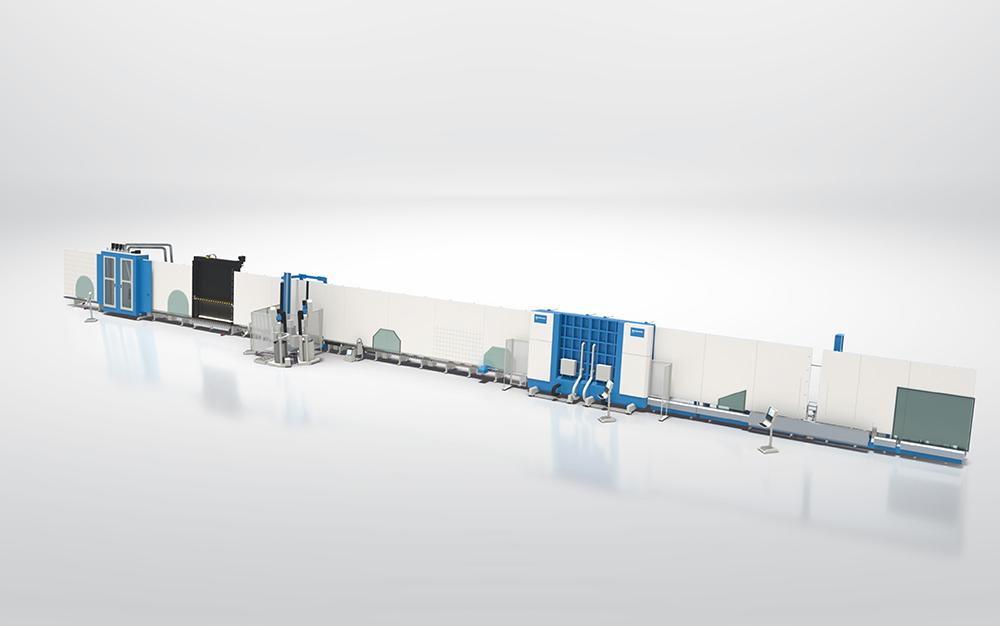

Tailor-made IG solution for Armour Sealed Units Ltd. in Bristol

Those who believe that insulating glass (IG) manufacturers are always located on industrial estates on the outskirts of towns are very much mistaken. The route to Armour Sealed Units passes through the centre of a quiet residential area in Bristol and ends in a cul-de-sac. An older building, measuring almost 250 square metres with the white-red company logo can be found at the end of this cul-de-sac. Company founder and owner Peter Crowley explains how his desire for an insulating glass line in the small factory was fulfilled thanks to Bystronic glass and tells of the challenges that had to be overcome.

Peter Crowley founded Armour Sealed Units Ltd. in 1983 and, since then, has been able to acquire numerous regular customers from the surrounding area for his insulating glass. Two years later, the family company – his son is the head of production and his wife takes care of the office work – moved to the current location. Initially, the insulating glass production was largely performed on a manual basis. Later, it was only the sealing that was performed manually. ”For a long time, I could not imagine that a complete insulating glass line including a sealing robot would fit in our small factory”, explains Peter. However, the entrepreneur was fully aware that he needed to invest in his production facility and modernise the old machinery in order to remain competitive and continue to be able to produce premium products that meet the current legal requirements.

”Bystronic glass was the only provider that was able to offer me a fully-equipped insulating glass line for my factory that only measures about 20 metres in length.What most impressed me was the fact that they did not want to force a standard solution full of compromises upon us, they fully recognised our production needs and the on-site conditions.”

Similar references

Press Glass Inc., U.S.A.

#automation #Flat laminating #glass processing #Laminating #ProL #reference #safety glass #Upgrades

Since establishing their presence in the US through an acquisition, Poland-based Press Glass has continued its brisk growth based on the same values that make it the #1 glass fabricator in Europe and the UK. The company’s latest US investment is a Glaston ProL convection control upgrade at its Ridgeway, Virginia, plant.

Lue lisääEmirates Glass, UAE

#architectural #automation #Flat tempering #glass tempering #iLooK #Jumbo Series #reference #safety glass #tempered glass

Emirates Glass LLC, one of the leading organizations in the glass industry and a long-time advocate of Glaston technology, continues its journey of innovation and quality enhancement with the installation of the Glaston Jumbo Series flat glass tempering line featuring Vortex Pro convection technology. This investment marks Emirates Glass’s commitment to delivering top-notch architectural glass solutions to the region and far beyond.

Lue lisääMid-American Glass, US

#appliances #architectural #automation #FC Series #Flat tempering #glass tempering #glass tempering process #RC Series #reference

“Maggie gives us outstanding flexibility to temper 3 to 19 mm glass. Louie gives us purpose – to temper the best heat-strengthened and heavy commercial insulated glass,” says Michelle Magyar, President of Mid-American Glass.

Lue lisääArticles

What if it was your child?

Safety is the most important characteristic of tempered glass. When broken, tempered glass breaks into small pieces that do not cause severe injuries as larger glass...

Lue lisääIR Dynamics at Step Change 2023 event

The company’s name is IR Dynamics, and we specialize in making vanadium dioxide thermochromic material that goes onto the glass. Being here at the Step Change...

Lue lisääeLstar Dynamics at Step Change 2023 event

We are eLstar Dynamics based in Eindhoven, the Netherlands. We are developing dynamic glass technology, which has the widest range on the market at the moment. Our...

Lue lisää