Mid-American Glass, US

Reference - Americas

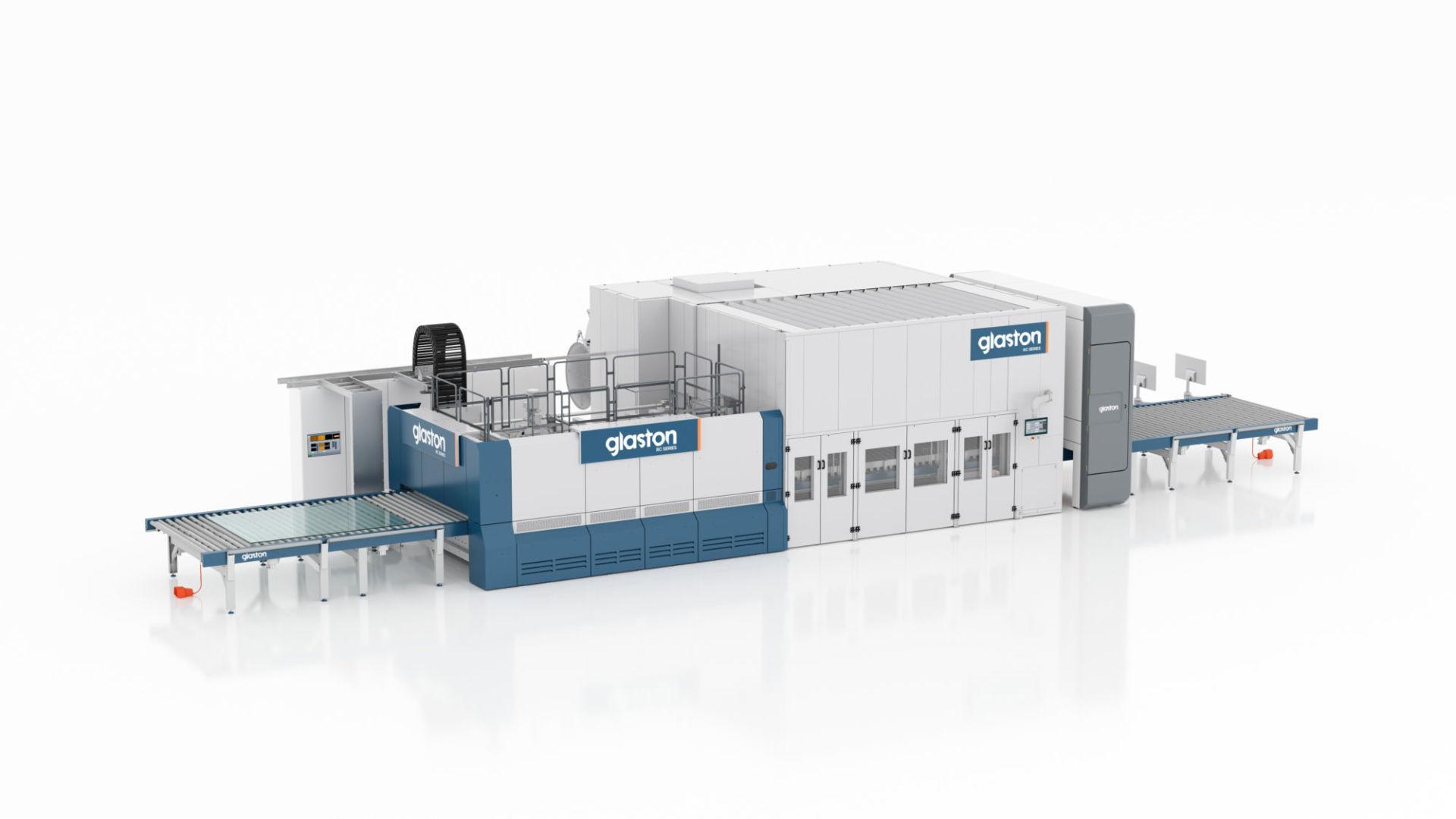

Glaston’s RC Series joins existing FC line - Maggie meets Louie Noodles

“Maggie gives us outstanding flexibility to temper 3 to 19 mm glass. Louie gives us purpose – to temper the best heat-strengthened and heavy commercial insulated glass,” says Michelle Magyar, President of Mid-American Glass.

Not many tempering furnaces are fortunate to be christened with human names. But then, not many have an owner who treats them as family, just as she does her team of talented personnel. Together, they have helped Mid-American Glass (MAG) grow and expand with additional factory space and a brand-new Glaston tempering furnace – the RC Series. Recently, it joined the company’s first Glaston tempering furnace, the third FC line at the time in North America.

Michelle contacted Glaston at the end of August 2020. Jim Hartley came to talk about ways Glaston could help Michelle get more out of Maggie. But Michelle had another idea. “I want to buy the Glaston RC Series furnace,” she insisted. “When can I get the paperwork?”

Once again, Michelle had been doing her homework. She had collected opinions from others in the field and heard lots of positive comments about Glaston’s RC 350 Series.

MAG’s customers were evolving. Michelle needed to go where her customers were taking the business – toward heat-strengthened and heavy commercial insulated glass.

“Louie Noodles, as we call the RC Series line, was my grandmother’s nickname for my father,” Michelle explains. “It fits them both perfectly – a strong workhorse that knows exactly what it needs to do. As my operators say: ‘Louie eats up glass.’” Louie’s 110” x 190” bed provides the company with 60% greater capacity than Maggie.

Michelle turned all RC Series project management over to Weston Grove, who joined MAG about five years ago as Processing and Quality Engineer. Wes supervised the building construction, checked the drawings and oversaw the installation.

Both Michelle and Wes praise Vishal Haswani and Petri Mattila, Glaston’s technicians, for their work. “They were diligent and precise,” Wes says. “It was amazing how they paid attention to details. They wanted everything to be less than 1 mm off – even the squareness of the walls – just to make sure the machine would sit perfectly.” Vishal even made the electricians rewire the furnace, as he said the electrical cables looked like a rat’s nest.

“I didn’t even look at any other suppliers. Ever since we got Maggie, I have been very satisfied with the relationship we have with Glaston and the quality. For me, it’s essential to work with suppliers who stay with you throughout the lifecycle of the equipment – far beyond the point of sale.”

Similar references

Pilkington Automotive Finland, Finland

#automotive glass #automotiveindustry #CNC #CNC96 #lifecycleservices #mobility #reference #Upgrades

“We decided to extend the lifetime of our Bystronic (now Glaston) automotive glass cutting equipment with a Glaston CNC96 upgrade kit and ensure that we can continue to get spare parts,” says Matti Säynäväjärvi, Technical Services Group Leader, Pilkington Automotive Finland Oy, Laitila plant.

Lue lisääViridian Glass, Australia

#architectural #automation #COMFORT #glass quality #IG unit #insulating glass #reference

As building regulations require more energy-efficient glass, Viridian Glass has stepped up its game. Purchasing Glaston’s COMFORT BOX IG manufacturing line enables its Woodville plant in Adelaide to meet burgeoning demands with visibly better quality and shorter lead times. “High quality insulated glass is the future in Australia,” says, National Operational Excellence Manager, Tarun Bhatia at Viridian Glass.

Lue lisääAGP, New Zealand

#architectural #automation #autopilot #digitalization #FC Series #flat glass tempering #reference

“We’re now running with the stability, reliability and consistency we aimed to achieve when we invested in Glaston’s Autopilot,” David Bunting, Managing Director of Architectural Glass Products (AGP), says.

Lue lisääArticles

Breakthroughs in automating glass processing

From traditional applications to cutting-edge capabilities, automation revolutionizes production, enhances quality and boosts efficiency. In this blog, we’ll discuss...

Lue lisääKey takeaways from glasstec 2024

Held in late October, glasstec 2024 buzzed with energy, robotic solutions and serious discussions. Based on what we saw and heard at the event, we can outline a...

Lue lisääKey applications of automation in glass processing

What glass processes gain the most from automation? In this blog, we’ll focus on some of the particularly promising application areas. As we discovered in the...

Lue lisää