Paragon Tempered Glass, U.S.A.

Reference - Americas

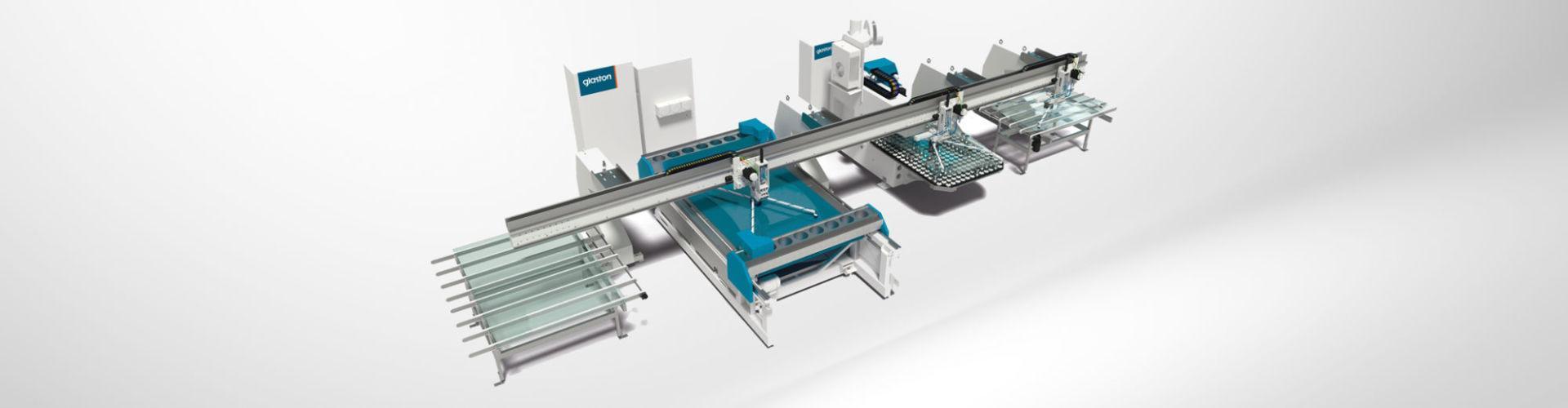

Glaston’s CHAMP 25 helps Paragon meet growing demands

“When we saw the CHAMP 25 a few years ago, we knew this was the future we should pursue for our next round of capital expenditures,” says Dan Wright, CEO of Paragon Tempered Glass.

Dan and his colleague Wes Brigner, Director of Manufacturing, already knew Bystronic glass and Glaston well from their vast experience in the glass industry. The two Paragon plants have 30-year-old Bystronic glass pre-processing equipment and Glaston tempering lines.

”We know that Glaston is very reliable, and the equipment does an awesome job,” says Wes. “We’ve always thought highly of the two equipment manufacturers that are now one Glaston.”

About two years ago, the men saw the CHAMP 25. They reached out to Glaston to learn more and decided it was the right path for their business.

“Not only would the line give us the speed and capacity we needed, we also knew our relationship with Glaston would be excellent and the quality would be of the highest caliber,” Dan says. And this all proved to be so – even down to the way the product was packaged and shipped.

“Of all the equipment we have purchased over the years, this machine came with the best packaging, instructions and top-of-the-line support,” Wes emphasizes. “When it came to support, the Glaston team had a response for us within minutes and a game plan to take care of any issue within an hour. This means the world to us!”

Paragon purchased their first CHAMP 25 in October 2019. Although COVID-19 slowed the process, the line was installed in September 2021. The new line incorporates four different processes – robotic loading, cutting, grinding and drilling with two sets of drills. Earlier, this would have taken four separate pieces of equipment. Now the line combines all processes into one and is tied into the company’s digital printer.

Automation opens door to greater capacity

CHAMP automates the processes, significantly improving yield and quality. At the same time, it helps Paragon focus on what they’re best at – fabricating a high volume of high value-added parts.

This is the direction their business is moving – providing parts with more holes and odder shapes – and serving new and different cab styles with a sharper look.

“Our operators are really excited about the CHAMP line, as they see this as the future. Especially at the Ohio plant, our people have adapted over the years to many changes and expect the best. They also know we share the business profits with our workforce. They understand that the better we do, the better they do, too,” Dan says.

Wes adds that the additional automation is helping them grow the business in a way they can excel without making the personnel work more hours.

“We’ve been short on team members and see automation as a way for us to work to live – and not live to work.”

Similar references

Pilkington Automotive Finland, Finland

#automotive glass #automotiveindustry #CNC #CNC96 #lifecycleservices #mobility #reference #Upgrades

“We decided to extend the lifetime of our Bystronic (now Glaston) automotive glass cutting equipment with a Glaston CNC96 upgrade kit and ensure that we can continue to get spare parts,” says Matti Säynäväjärvi, Technical Services Group Leader, Pilkington Automotive Finland Oy, Laitila plant.

Lue lisääViridian Glass, Australia

#architectural #automation #COMFORT #glass quality #IG unit #insulating glass #reference

As building regulations require more energy-efficient glass, Viridian Glass has stepped up its game. Purchasing Glaston’s COMFORT BOX IG manufacturing line enables its Woodville plant in Adelaide to meet burgeoning demands with visibly better quality and shorter lead times. “High quality insulated glass is the future in Australia,” says, National Operational Excellence Manager, Tarun Bhatia at Viridian Glass.

Lue lisääAGP, New Zealand

#architectural #automation #autopilot #digitalization #FC Series #flat glass tempering #reference

“We’re now running with the stability, reliability and consistency we aimed to achieve when we invested in Glaston’s Autopilot,” David Bunting, Managing Director of Architectural Glass Products (AGP), says.

Lue lisääArticles

Breakthroughs in automating glass processing

From traditional applications to cutting-edge capabilities, automation revolutionizes production, enhances quality and boosts efficiency. In this blog, we’ll discuss...

Lue lisääKey takeaways from glasstec 2024

Held in late October, glasstec 2024 buzzed with energy, robotic solutions and serious discussions. Based on what we saw and heard at the event, we can outline a...

Lue lisääKey applications of automation in glass processing

What glass processes gain the most from automation? In this blog, we’ll focus on some of the particularly promising application areas. As we discovered in the...

Lue lisää