Pavle, Serbia

Reference - Europe

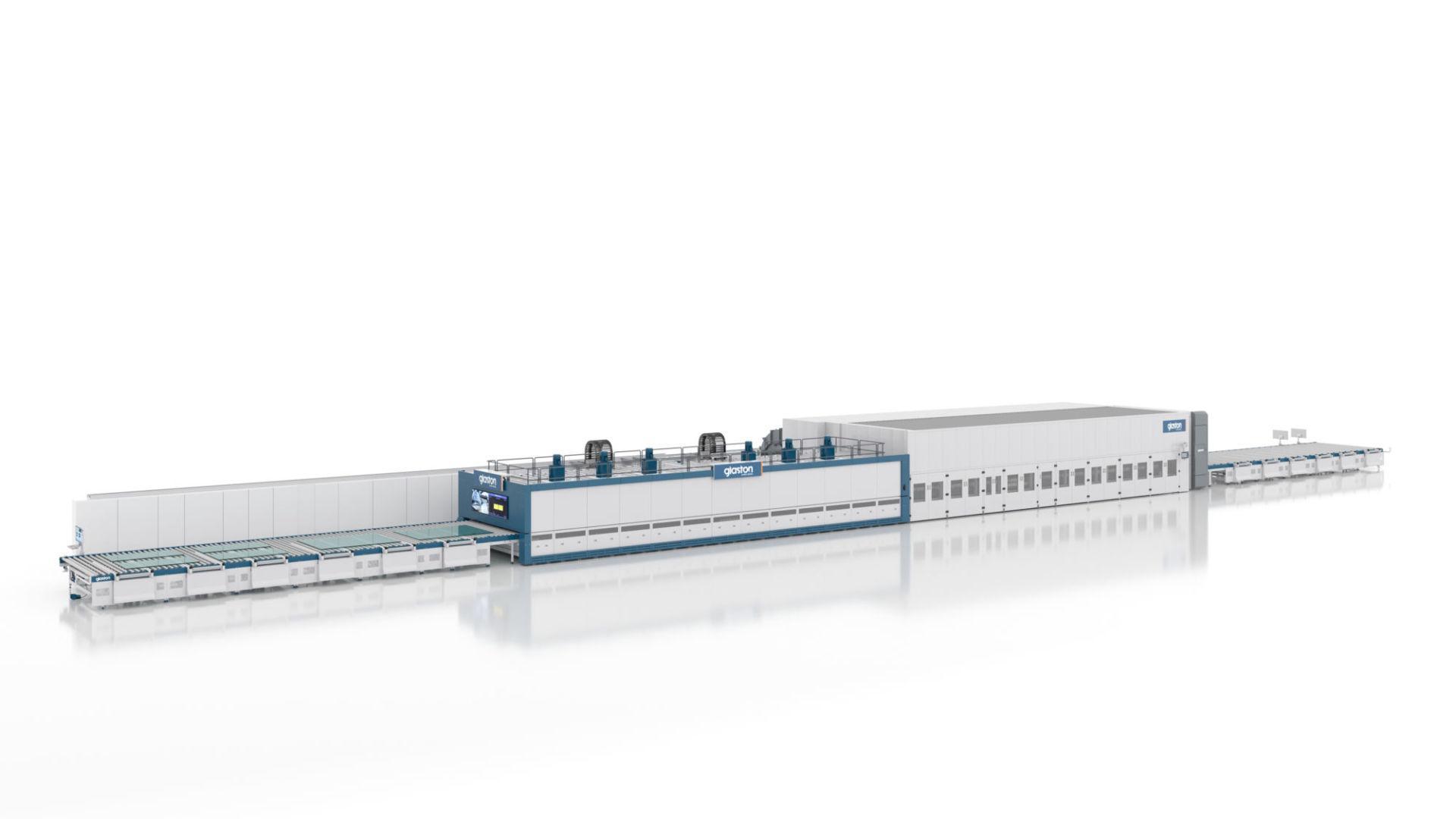

Pavle invests in Glaston’s Jumbo Series tempering line

“With our Glaston Jumbo furnace and insulating line, we can now produce the biggest IG units in the Balkans, and our business is taking off internationally. The line helps us serve architects who want ever-larger, top-quality windows for offices, schools and even shopping malls with glass sizes up to 3.5 meters or more,” says Jelena Blagojevic, Marketing Manager of Pavle.

Pavle Pančevo, located about 20 kilometers northeast of Belgrade, Serbia, has grown from humble beginnings. Founder Pavle Tmušić began as a delivery driver for glass products and went on to become a reseller. From there, he started processing glass himself and founded Pavle Pančevo with his late wife Zorica in 1992. Today, the family-owned business is still very much in the hands of the family members. Jelena Tmušić Blagojevic, Marketing Manager; Marko Tmušić General Manager, and Marija Jovicevic, CFO, are the owner’s children.

In 2006, Pavle invested in its first Glaston tempering line – the ProE. “At the time, it was not very easy to get information on glass processing machinery like you can today through the Internet,” Jelena says. “So, my father traveled to meet a few companies with furnaces – and at each location, he was told that the best machinery came from Glaston, then Tamglass.”

“We’re thankful for that decision. It wasn’t easy then – and it wasn’t any easier this time either, because the Jumbo tempering line was a huge investment for us,” Jelena says. “We received many bids, honestly,” she continues. “When we sat down and talked about it, we realized we were so happy with the quality of our Glaston ProE, the service, the installation support – there was no other option. But we know we made the right choice. The furnace quality really sets Glaston apart from the rest.” Pavle decided to go with the Glaston Jumbo Series around the beginning of 2021, while still during the COVID-19 pandemic. The Glaston Jumbo Series was delivered in February 2022 and started running the same summer.

“It has been most important for us to use the size of the furnace to our advantage,” says Marko Tmušić. “We can process a lot of glass simultaneously, which drastically improves our production time. If an order needs to be ready in two weeks, we can process it in 7 to 10 days, greatly speeding up our deliveries.”

“For our customers, the most important factor is the speed, especially with colored or enameled glass. Even with Low-E and special coatings, our production speed has given us a competitive edge.”

Similar references

Pilkington Automotive Finland, Finland

#automotive glass #automotiveindustry #CNC #CNC96 #lifecycleservices #mobility #reference #Upgrades

“We decided to extend the lifetime of our Bystronic (now Glaston) automotive glass cutting equipment with a Glaston CNC96 upgrade kit and ensure that we can continue to get spare parts,” says Matti Säynäväjärvi, Technical Services Group Leader, Pilkington Automotive Finland Oy, Laitila plant.

Lue lisääViridian Glass, Australia

#architectural #automation #COMFORT #glass quality #IG unit #insulating glass #reference

As building regulations require more energy-efficient glass, Viridian Glass has stepped up its game. Purchasing Glaston’s COMFORT BOX IG manufacturing line enables its Woodville plant in Adelaide to meet burgeoning demands with visibly better quality and shorter lead times. “High quality insulated glass is the future in Australia,” says, National Operational Excellence Manager, Tarun Bhatia at Viridian Glass.

Lue lisääAGP, New Zealand

#architectural #automation #autopilot #digitalization #FC Series #flat glass tempering #reference

“We’re now running with the stability, reliability and consistency we aimed to achieve when we invested in Glaston’s Autopilot,” David Bunting, Managing Director of Architectural Glass Products (AGP), says.

Lue lisääArticles

Breakthroughs in automating glass processing

From traditional applications to cutting-edge capabilities, automation revolutionizes production, enhances quality and boosts efficiency. In this blog, we’ll discuss...

Lue lisääKey takeaways from glasstec 2024

Held in late October, glasstec 2024 buzzed with energy, robotic solutions and serious discussions. Based on what we saw and heard at the event, we can outline a...

Lue lisääKey applications of automation in glass processing

What glass processes gain the most from automation? In this blog, we’ll focus on some of the particularly promising application areas. As we discovered in the...

Lue lisää