Semcoglas, Germany

Reference - Europe

Semcoglas uses insulating glass with thermoplastic spacers

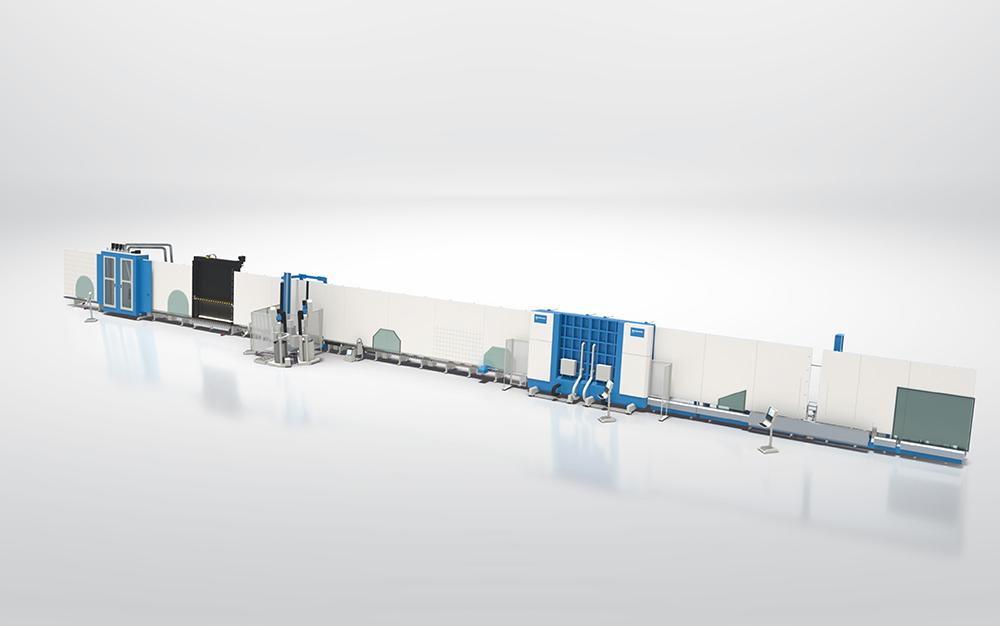

When Semcoglas added the German Aschaffenburg location to its Company Group in October 2003, the production facility only had an old glass cutting facility and a small insulating glass line at its disposal. Since the start of this year, Semcoglas has now been working with an ultra-modern Bystronic glass production line for the manufacture of insulating glass which uses glass supplied by a rapid HEGLA insulating glass feed system.

The new insulating glass line measures 64 metres in length and processes glass sizes ranging from 19 x 35 centimetres up to 2.70 x 5.00 metres. In doing so, the production is completely focused on the current and future requirements of the insulating glass customers.

The Company Group produces insulating glass in 15 of the 20 branches and has used Bystronic glass production lines for many years – mostly including the tps’applicator for the processing of thermoplastic spacers. ”We made the conscious decision to invest in this future-oriented technology as it is one of the most advanced warm edge technologies on the market: The thermoplastic edge bond simultaneously replaces a conventional metallic spacer, the desiccant and the primary seal”, explains Michel Schüller, Technical Branch Manager in Aschaffenburg and son of the Managing Partner of the Semcoglas Group, Hermann Schüller. He goes on to explain: ”As a result, the thermal bridges found at the edge of the insulating glass are considerably reduced compared to the conventional spacers, thus improving the internal temperature.”

”The use of thermoplastic spacers is of particular benefit when producing triple insulating glass units as both spacers are automatically applied without any offset whatsoever – even when dealing with shaped formats. As a result, we are able to achieve better quality even in terms of visual appearance. Semcoglas customers also appreciate this”

Similar references

Pavle, Serbia

#architectural #automation #flat glass tempering #glass tempering #iControL #Jumbo Series #reference #safety glass #tempered glass

“With our Glaston Jumbo furnace and insulating line, we can now produce the biggest IG units in the Balkans, and our business is taking off internationally. The line helps us serve architects who want ever-larger, top-quality windows for offices, schools and even shopping malls with glass sizes up to 3.5 meters or more,” says Jelena Blagojevic, Marketing Manager of Pavle.

Lue lisääLippert Components, USA

#automation #automotive #automotive glass #bending #champ #CHF #glass bending #glass tempering #MATRIX #mobility #reference #safety glass

Tim Widner at Lippert Components in the US is sharing his and his team's experiences working with the Glaston glass processing machinery. "The new equipment has been a great addition to us. We are able to one-piece flow our raw material through our line, hands-free. No humans come in contact with the glass until it is fully tempered and at the end of the process."

Lue lisääPress Glass Inc., U.S.A.

#automation #flat glass laminating #glass processing #laminating #ProL #reference #safety glass #Upgrades

Since establishing their presence in the US through an acquisition, Poland-based Press Glass has continued its brisk growth based on the same values that make it the #1 glass fabricator in Europe and the UK. The company’s latest US investment is a Glaston ProL convection control upgrade at its Ridgeway, Virginia, plant.

Lue lisää